Brewing beer is a complex, multi-stage process that requires robust, reliable and sustainable processing solutions. The brewing process involves the use of viscous, abrasive and shear-sensitive raw materials which can be difficult to handle. Top brand beers require dependable fluid handling equipment to maintain their consistent high quality whilst all the time striving for production efficiency.

The efficiency of your brewing process is achieved through increased uptime and reduced costs. Our products can help to

- Lower energy usage

- Reduce product wastage

- Simplify and accelerate process equipment maintenance

- The highly competitive nature of the beverage market is subject to an increasing number of strict regulations necessitating compliance to hygiene and energy-efficiency standards.

At Watson-Marlow Fluid Technology Solutions, we rigorously test our complete product range—and audit our supply chain—to ensure a secure supply of products that meet the most up to date regulatory frameworks. Backed by a global network of specialist engineers and technical support team, we partner with you to simplify the design and engineering processes at your facility.

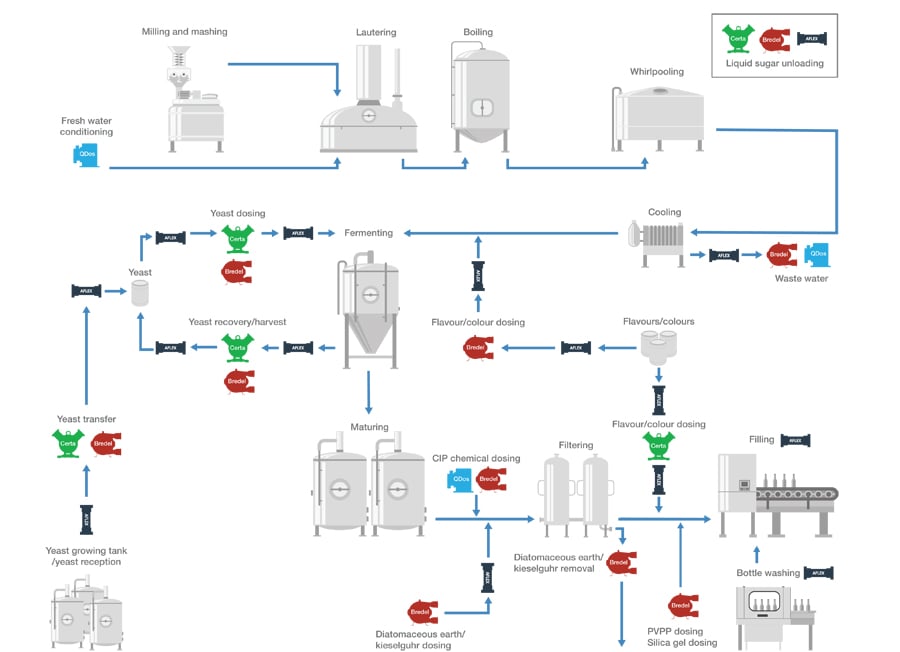

Beer production process

A brewing process typically begins with barley, which is used to produce the wort via malting, mashing and lautering stages. Once the wort is prepared, it is boiled with hops and other key ingredients depending on the specific brew before whirlpooling removes unwanted solids.

Once cooled, the wort enters the crucial fermentation stage where yeast is added (pitched) to start the process of turning sugar into alcohol and carbon dioxide, both of which must be precisely controlled to produce a high quality and consistent beer.

The fermented beer is then matured in conditioning tanks until the desired characteristics, such as flavour and aroma are achieved. Finally the brew is filtered and packaged (bottled, canned, kegged etc.). The basic process is essentially the same whether the brewer is a small craft brewery or a large industrial scale beer producer.

Quality processing equipment and specialist support

Whether carefully handling yeast, accurately dosing additives, pumping abrasive diatomaceous earth or metering water treatment chemicals, Watson-Marlow Fluid Technology Solutions can offer a pumping solution to optimise all stages of your brewing process.

Our innovative range of peristaltic and sinusoidal pumps ensure that the product is transferred or dosed accurately and hygienically without damage, offering the following benefits to brewers.

- Gentle, low shear pumping action

- Highly accurate

- High suction capability

- Abrasives handling

- Viscous fluid handling

- Self-priming and dry-running

- Hygienic, aseptic design and CIP/SIP capability

- No seals or valves to block

- Minimal, easy and low cost maintenance

- Energy-efficient

- In addition to brewery process pumps, Watson-Marlow Fluid Technology Solutions offer other specialist fluid handling products such as the Aflex range of PTFE-lined hose assemblies which are ideal for the brewing industry.

Our diverse product range is backed by a global network of specialist engineers who can provide fluid management solutions to your process.

Brewing processes

-

![]()

Filtration in brewing

Improving accuracy and quality whilst reducing costs during beer filtration

-

![]()

Dosing in brewing

Our products help to increase accuracy and improve quality in additive dosing and CIP chemical...

-

![]()

Yeast handling in brewing

View our range of peristaltic and sinusoidal pumps help protect pumped yeast from degradation.

Key products

-

![Certa pump]()

Certa pump

Low shear, virtually no pulsation EHEDG Type EL Aseptic Class I certifed pump. Up to 50 % less power than other pumps.

Pumps - sine pumps

Products by brand

-

![]()

MasoSine for Food and Beverage

View our MasoSine process pumps used in the food and beverage sector

-

![]()

Watson-Marlow Pumps for Food and Beverage

Peristaltic process pumps for use in food and beverage processes

-

![]()

Bredel hose pumps for Food and Beverage

View Bredel hose pumps for use in food and beverage processes

-

![]()

Aflex PTFE flexible hoses for Food and Beverage

PTFE hoses for food and beverage processes

-

![]()

Watson-Marlow Tubing for Food and Beverage

View our peristaltic tubing for use in food and beverage processes

Case studies

-

Case Study

![]()

High suction pumps reduce yeast harvesting time

View the full case study for yeast harvesting.

Case Study

-

Case Study

![]()

Gentle yeast transfer in Canadian Pilsner beer production

View the full Steam Whistle Brewery Case study.

Case Study