Certa and Certa Compact pump

Overview

Certa process pumps

Engineers in food and beverage and hygienic solution plants are frequently faced with pumping a wide range of products from high-viscosity orange juice concentrates and bakery products to sheer sensitive products like deli salads, cheese curds and savoury pie fillings. Certa meets the highest standards in hygiene and cleanability combined with improving process efficiency and minimising total cost of ownership.

Hygienic design

- EHEDG Type EL - Class I

- Now with EHEDG Type EL Aseptic Class I

- All contact parts FDA and EG1935 compliant

Virtually pulse free

- Smooth product flow, no need for ancillary dampeners

- Up to 255,000 L/h, 8 million cP and 15 bar

Low shear handling

- Prevents aeration foaming

- Improves yield and maintains product quality

Lowest cost of ownership

- Reduced CIP cycle time and reduced cleaning agents

- Maintenance can be carried out within minutes. Pump can remain in the system for maintenance. No need to take it to the maintenance shop.

Energy efficient

- Up to 50 % less power consumption than lobe or circumferential pumps

- Higher energy efficiency at higher viscosities

Features and benefits

- Gentle product handling preserves high quality of product - superior viscous handling

- EHEDG Type EL Class I - now also with EHEDG Type EL Aseptic Class I

- Impressive suction capability: -12.3 psi (atm)

- Low shear and virtually no pulsation

- Outstanding energy efficient pumping principle - up to 50 % less power than other pumps

- Only one shaft and one seal system - different port orientations available

- Bi-directional running

- Two year warranty

Technical summary

| Max. flow rate | 255000 L/h |

| Max. flow rate | 1124 USGPM |

| Volume per revolution | 0.08 - 10.64 L |

| Volume per revolution | 0.021 - 2.81 USG |

| Max. particle size | 13 - 100 mm |

| Max. particle size | 0.51 - 3.9 in |

| Standards | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic |

| Certification and compliance | EC 1935/2004, FDA |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

Performance

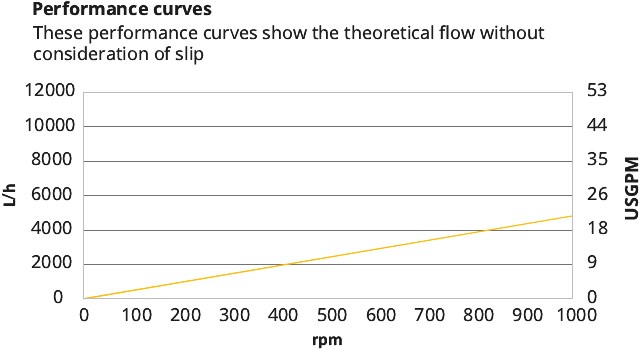

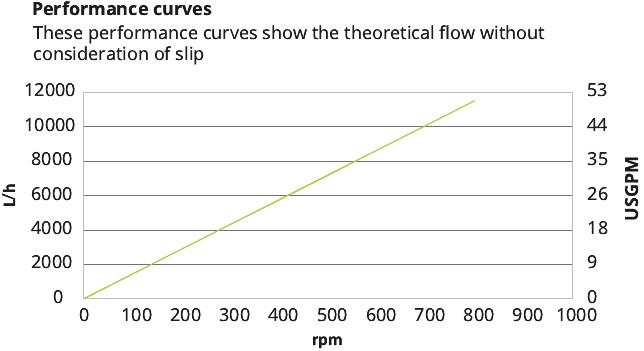

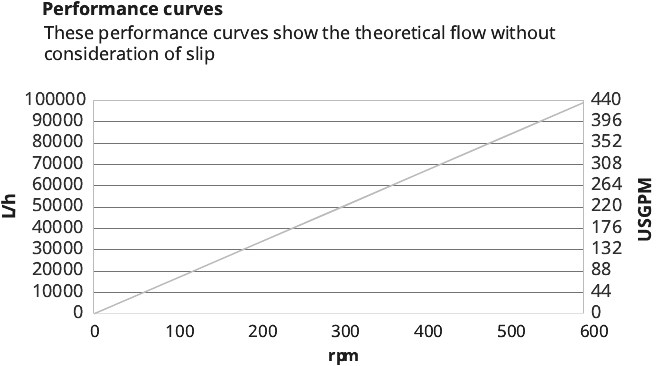

Certa 100 / Certa Compact performance

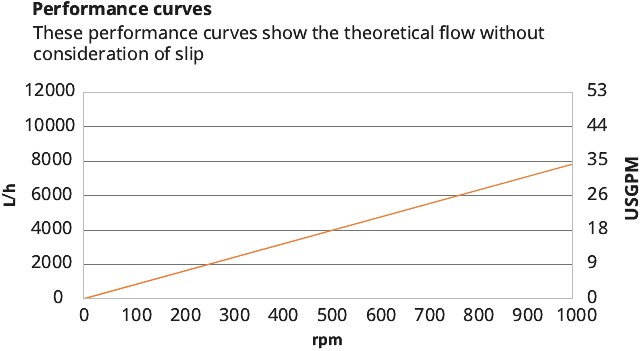

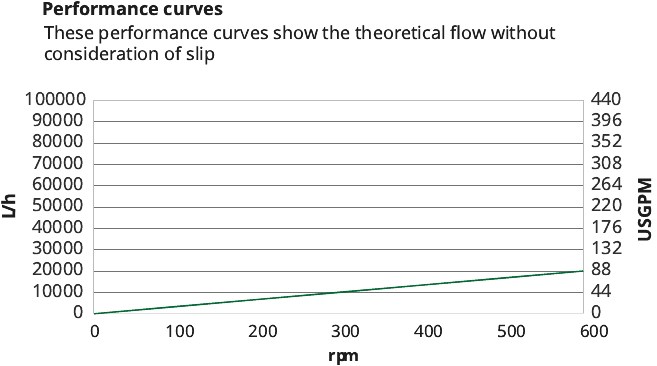

Certa 200 / Certa Compact performance

Certa 250 / Certa Compact performance

Certa 300 / Certa Compact performance

Certa 400 / Certa Compact performance

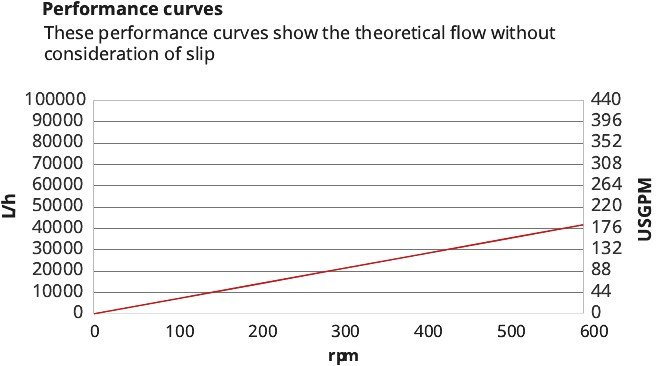

Certa 500 / Certa Compact performance

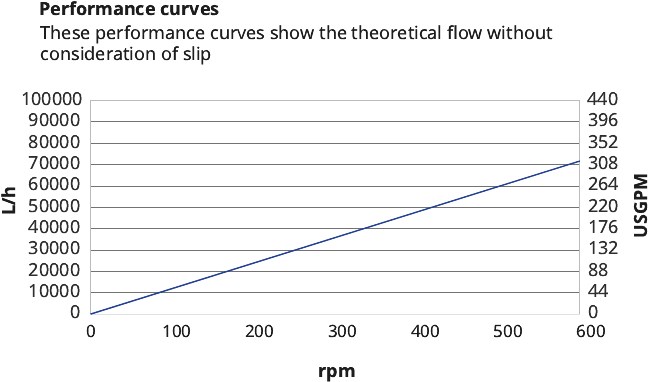

Certa 600 / Certa Compact performance

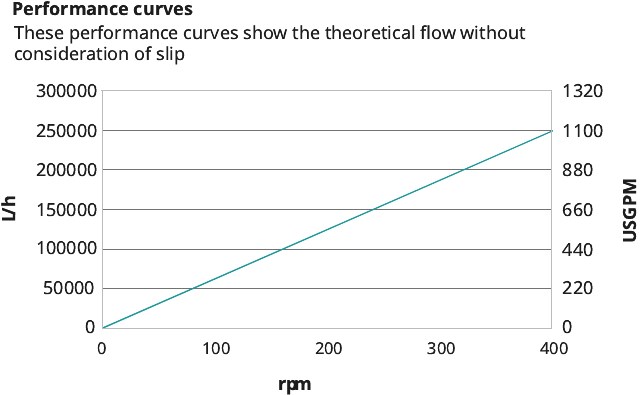

Certa 800 performance

Specifications

Technical specifications

| Certa 100 / Certa Compact | Certa 200 / Certa Compact | Certa 250 / Certa Compact | Certa 300 / Certa Compact | Certa 400 / Certa Compact | Certa 500 / Certa Compact | Certa 600 / Certa Compact | Certa 800 | |

| Volume per revolution | 0.021 USG (0.08 L) | 0.034 USG (0.13 L) | 0.063 USG (0.24 L) | 0.132 USG (0.5 L) | 0.305 USG (1.16 L) | 0.505 USG (1.92 L) | 0.724 USG (2.75 L) | 2.81 USG (10.64 L) |

| Max. particle size | 0.51 in (13 mm) | 0.71 in (18 mm) | 0.87 in (22 mm) | 1.18 in (30 mm) | 1.5 in (38 mm) | 1.97 in (50 mm) | 2.36 in (60 mm) | 3.9 in (100 mm) |

| Suction pressure | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum | 85% of a vacuum |

| Maximum operating pressure | 87, 145 psi (6, 10 bar) | 87, 145 psi (6, 10 bar) | 87, 217 psi (6, 15 bar) | 87, 217 psi (6, 15 bar) | 87, 217 psi (6, 15 bar) | 87, 217 psi (6, 15 bar) | 87, 217 psi (6, 15 bar) | 217 psi (15 bar) |

| Operating temperature | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) | -4 °F to 212 °F (-20 °C to 100 °C) |

| Max. SIP temperature | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) | 250 °F (121 °C) |

| Standards | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic | 3-A, ATEX, EHEDG Type El Class I, EHEDG Type EL Class I Aseptic |

| Certification and compliance | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA | EC 1935/2004, FDA |

| Port orientation | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements | Various options to meet your requirements |

| Port type | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC | Flange, Milk fitting, Others available on request, RJT, SMS, TC |

| Shaft diameter | 0.98 in (28 mm) | 0.98 in (28 mm) | 0.98 in (28 mm) | 1.97 in (50 mm) | 1.97 in (50 mm) | 1.97 in (50 mm) | 2.56 in (65 mm) | 4.33 in (110 mm) |

| Shaft height | 3.74 in (95 mm) | 4.31 in (109.5 mm) | 5.91 in (150 mm) | 6.69 in (170 mm) | 7.87 in (200 mm) | 9.84 in (250 mm) | 10.04 in (255 mm) | 15.94 in (405 mm) |

| Pump size | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Nozzles | Length | ||||||||||||||||

| N1 | N2 Certa | N2 Certa Compact | N3 | L1 Certa | L1 Certa Compact | L2 Certa | L2 Certa Compact | |||||||||||

| mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | |||

| Certa 100 | 139 | 5.472 | 228 - 25 | 8.976 - 0.984 | 220 ± 25 | 8.661 ± 0.984 | 10 | 0.394 | 265 | 10.079 | 122.5 | 4.823 | 730 | 28.740 | 320 | 12.598 | ||

| Certa 200 | 155 | 6.102 | 242.5 - 25 | 5.610 - 0.984 | 230 ± 25 | 9.055 ± 0.984 | 10 | 0.394 | 299 | 11.772 | 124 | 4.882 | 730 | 28.740 | 370 | 14.567 | ||

| Certa 250 | 192 | 7.559 | 281 - 25 | 11.063 - 0.984 | 270 ± 25 | 10.630 ± 0.984 | 12 | 0.472 | 352 | 13.858 | 134.5 | 5.295 | 850 | 33.465 | 400 | 15.748 | ||

| Certa 300 | 238 | 9.370 | 305 - 35 | 12.008 - 1.378 | 263 ± 25 | 10.354 ± 0.984 | 18 | 0.709 | 456 | 17.953 | 149 | 5.866 | 1100 | 43.307 | 480 | 18.898 | ||

| Certa 400 | 324 | 12.756 | 322 - 35 | 12.677 - 1.378 | 329 ± 25 | 12.953 ± 0.984 | 31 | 1.221 | 514 | 20.236 | 174 | 6.850 | 1300 | 51.181 | 600 | 23.622 | ||

| Certa 500 | 327 | 12.874 | 378 - 35 | 14.882 - 1.378 | 335 ± 25 | 13.189 ± 0.984 | 25 | 0.984 | 564 | 22.205 | 210 | 8.268 | 1300 | 51.181 | 600 | 23.622 | ||

| Certa 600 | 343 | 13.504 | 380 - 35 | 14.961 - 1.378 | 352 ± 25 | 13.858 ± 0.984 | 28 | 1.102 | 639 | 25.158 | 252.5 | 9.941 | 1400 | 55.118 | 650 | 25.591 | ||

| Certa 800 | 535 | 21.063 | 740 | 29.134 | N/A | N/A | 38 | 1.496 | 807 | 31.771 | N/A | N/A | 2200 | 86.614 | N/A | N/A | ||

| Pump weight | ||

|---|---|---|

| Model | kg | lb |

| Certa 100 | 44 | 97 |

| Certa 100 Compact | 25.5 | 56 |

| Certa 200 | 49 | 108 |

| Certa 200 Compact | 34 | 75 |

| Certa 250 | 89 | 196 |

| Certa 250 Compact | 52 | 115 |

| Certa 300 | 124 | 273 |

| Certa 300 Compact | 79.5 | 175 |

| Certa 400 | 215 | 474 |

| Certa 400 Compact | 164.5 | 363 |

| Certa 500 | 344 | 758 |

| Certa 500 Compact | 231.5 | 510 |

| Certa 600 | 508 | 1120 |

| Certa 600 Compact | 411 | 906 |

Materials of construction

| Housing | Stainless steel 1.4404, Stainless steel 316L |

| Bearing frame | Stainless steel 1.4301, Stainless steel 304 |

| Rotor | A276 (CF10SMnN), A494, Hardened and chrome plated |

| Gate | MWR, PA6GF30, PEEK, Polyamide, POM metal detectable, PTFE, WRP, WRP PUR-Inlay |

| Seals/gaskets | EPDM, FKM, Others available on request |

| Mechanical seal | SiC/Ca-PTFE, SiC/SiC-PTFE |

| Double Mechanical seal | SiC/SiC |

| Shaft seal | PTFE, SSIC |

| O-Ring seal system | FKM |

| Single Lip seal system | PUR |

Documentation

Brochures

-

Certa pump brochure (US).pdf

PDF - 1mb -

Certa pump aftercare (US).pdf

PDF - 183.5kb -

Food and Beverage overview (US).pdf

PDF - 1.3mb -

Personal care sector (US).pdf

PDF - 1mb

Datasheets

-

Certa 800 datasheet (US).pdf

PDF - 1.2mb -

Certa 250 Certa Compact datasheet (US).pdf

PDF - 1.2mb -

Certa 500 Certa Compact datasheet (US).pdf

PDF - 1.3mb -

Certa 200 Certa Compact datasheet (US).pdf

PDF - 1.3mb -

Certa 300 Certa Compact datasheet (US).pdf

PDF - 1.3mb -

Certa 400 Certa Compact datasheet (US).pdf

PDF - 1.3mb -

Certa 600 Certa Compact datasheet (US).pdf

PDF - 1.3mb -

Certa 100 Certa Compact datasheet (US).pdf

PDF - 1.2mb

Manuals

-

Certa Compact Manual (EN).pdf

PDF - 1.9mb -

Certa pump manual addendum (EN).pdf

PDF - 1.8mb -

Certa pump manual (EN).pdf

PDF - 9mb -

Certa 800 pump manual (EN).pdf

PDF - 1.9mb -

Certa pump COP addendum (EN).pdf

PDF - 812.8kb

Other Resources

-

Certa Compact Sustainability Scorecard.pdf

PDF - 342.8kb -

Certa 800 Mee sustainability curves (US).pdf

PDF - 146.2kb -

Certa 100 to 600 Mee sustainability curves (US).pdf

PDF - 4mb

Certification

The European Hygienic Engineering & Design Group (EHEDG) is a consortium of equipment manufacturers, food industries, research institutes as well as public health authorities and was founded in 1989 with the aim to promote hygiene during the processing and packing of food products. More

3-A SSI is an independent, not-for-profit corporation dedicated to advancing hygienic equipment design for the food, beverage, and pharmaceutical industries.

FDA is responsible for protecting the public health by assuring the safety, efficacy and security of human and veterinary drugs, biological products, medical devices, our nation’s food supply, cosmetics, and products that emit radiation.

REGULATION (EC) No 1935/2004 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 October 2004 on materials and articles intended to come into contact with food

ATEX Directive (2014/34/EU): Machinery and equipment manufacturers, their authorized representatives, importers, or any persons responsible for placing a product on the market, must ensure that equipment falling under the ATEX Directive (2014/34/EU) prevents, or limits the impact to an adequate level of safety, an ignition of explosive atmospheres. As a visible sign of compliance with ATEX, the CE marking must be affixed to the equipment.

Options and accessories

Options and accessories

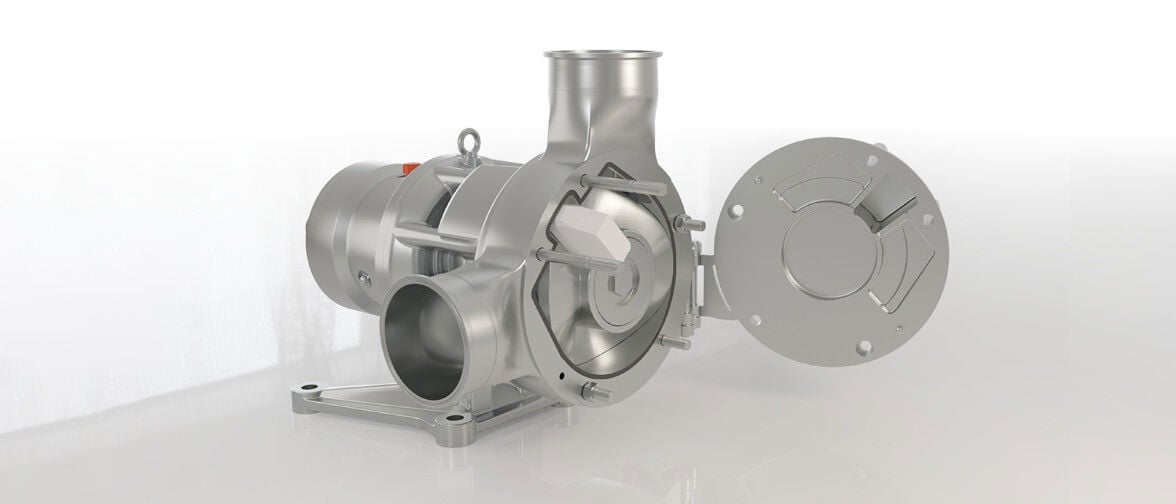

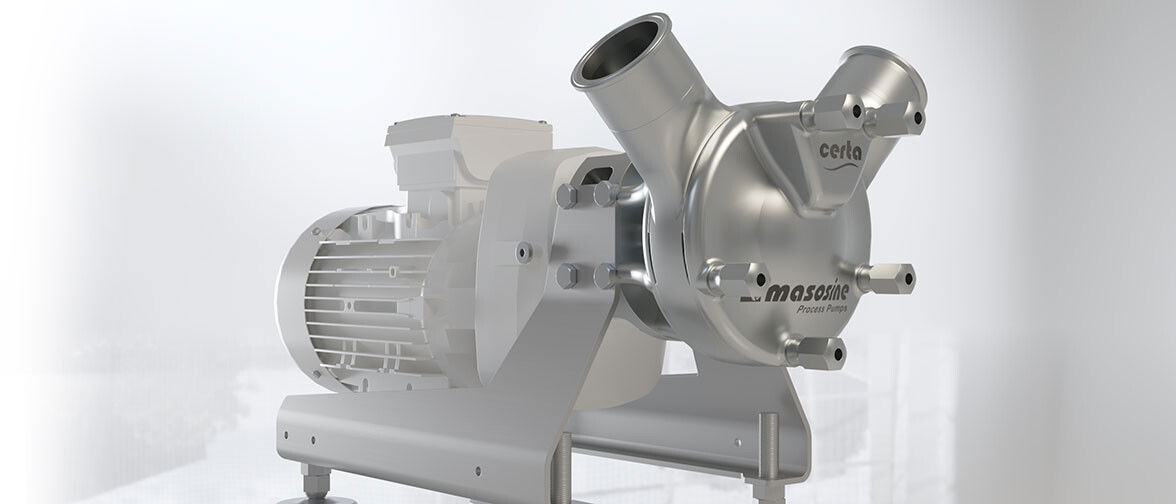

Certa Compact Sine pump

Limited on space?

With a 30% reduction in footprint on the Certa Sine pump from MasoSine, the Certa Compact Sine pump is a compact solution for customers when space for an installation is limited.

As with all Certa Sine pumps, the Certa Compact delivers energy savings as it consumes up to 50% less power than lobe or circumferential pumps with exceptional performance for all applications, including handling highly viscous products.

O-ring seal system

To support customers with clean out of place (COP) processes, Certa pumps are offered with an ergonomic hinge and O-ring seal system. The hybrid system includes a hexagonal locking screw and O-ring seal system to support frequent assembly and disassembly without the need for specialist tools or training. The O-ring seal provides additional protection against system vibration and cavitation.

Other options and accessories

- Pump jacketing to maintain the duty fluid temperature

- Static and dynamic flush systems available

- Single mechanical seal or single mechanical seal with flush

- Double mechanical seal, either flushed only or pressurized

- Flush and double mechanical seal can be retrofitted without any modification

Videos

Take a tour

Certa animation

Certa cut away

Certa clean in place

The video shows the MasoSine Certa pumps’ ability to clean in place even the toughest substances. For the purposes of this demonstration, mustard has been pumped and allowed to dry. Just cold water without a cleaning agent is then run through the pump, removing all traces of the mustard with ease.

Certa pumps are:

- Designed for CIP cleaning and SIP sterilisation

- Cleanability proven by EHEDG and 3A

- Food compliance materials: FDA and EG 1935

Maintenance Videos

Certa - Assembly

Certa - Dismantling

Certa - Changing pump orientation

Case studies

Related Products

-

![SPS pump]()

SPS pump

Low shear pumping with flow rates to 434 GPM and pressures up to 217 psi.

Pumps - sine pumps

Our pump specialists are here to help you succeed.

To order a product or ask a question