Bredel CIP hose pumps 40-50

Flow rates to 37 GPM (8500 L/h) and pressures up to 232 psi. Food quality hose compliant.

Pumps - hose pumps

The hose element is critical to ensure pump performance, durability and efficiency. Bredel composite reinforced hoses are constructed from high-quality compounded rubbers reinforced with four individual layers of braided nylon, and finished by high-precision machining. Inner and outer layers are extruded and, after construction, machined to ensure critical tolerances are maintained.

Excellent chemical resistance, especially to ketones, alcohols and concentrated acids.

Perfect 100 % compression eliminates slippage which can destroy shear sensitive product and reduce metering accuracy.

Examples of compatible media:

| Max. operating pressure | 16 bar |

| Max. operating pressure | 232 psi |

| Bore size | 10 - 100 mm |

| Bore size | 0.39 - 3.94 in |

| Wall thickness | 8.5 - 22 mm |

| Wall thickness | 0.337 - 0.866 in |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

| EPDM Hose 10 | EPDM Hose 15 | EPDM Hose 20 | EPDM Hose 25 | EPDM Hose 32 | EPDM Hose 40 | EPDM Hose 50 | EPDM Hose 65 | EPDM Hose 80 | EPDM Hose 100 | |

| Max. operating pressure | 145 psi (10 bar) | 145 psi (10 bar) | 145 psi (10 bar) | 232 psi (16 bar) | 232 psi (16 bar) | 232 psi (16 bar) | 232 psi (16 bar) | 232 psi (16 bar) | 232 psi (16 bar) | 232 psi (16 bar) |

| Max. suction capability | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 354 inWC (9 mWC) | 335 inWC (8.5 mWC) | 256 inWC (6.5 mWC) |

| Suction capability (80% Flow rate) | 8.5 mWC ( 335 inWC) | 8.5 mWC ( 335 inWC) | 8.5 mWC ( 335 inWC) | 8.5 mWC ( 335 inWC) | 8.5 mWC ( 335 inWC) | 8.5 mWC ( 335 inWC) | 7 mWC ( 276 inWC) | 7 mWC ( 276 inWC) | 6 mWC ( 236 inWC) | 4.5 mWC ( 177 inWC) |

| Operating temperature | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) | -4 °F to 113 °F (-20 °C to 45 °C) |

| Fluid temperature ranges | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) | 14 °F to 176 °F (-10 °C to 80 °C) |

| Bore size | 0.39 in (10 mm) | 0.59 in (15 mm) | 0.79 in (20 mm) | 0.98 in (25 mm) | 1.26 in (32 mm) | 1.57 in (40 mm) | 1.97 in (50 mm) | 2.56 in (65 mm) | 3.15 in (80 mm) | 3.94 in (100 mm) |

| Wall thickness | 0.413 in (10.5 mm) | 0.413 in (10.5 mm) | 0.337 in (8.5 mm) | 0.555 in (14.1 mm) | 0.571 in (14.5 mm) | 0.52 in (13.2 mm) | 0.591 in (15 mm) | 0.673 in (17.1 mm) | 0.827 in (21 mm) | 0.866 in (22 mm) |

| Length | 20.1 in (510 mm) | 29.7 in (755 mm) | 29.7 in (755 mm) | 39.9 in (1005 mm) | 49.2 in (1250 mm) | 58.7 in (1490 mm) | 71.7 in (1820 mm) | 91.1 in (2340 mm) | 109.4 in (2780 mm) | 129.1 in (3280 mm) |

| Weight | 0.88 lbs (0.4 kg) | 1.76 lbs (0.8 kg) | 1.32 lbs (0.6 kg) | 4.41 lbs (2 kg) | 6.61 lbs (3 kg) | 7.72 lbs (3.5 kg) | 13.23 lbs (6 kg) | 26.46 lbs (12 kg) | 46.3 lbs (21 kg) | 66.14 lbs (30 kg) |

| Material | EPDM |

| Inner layer | EPDM |

| Outer layer | NR |

|

|

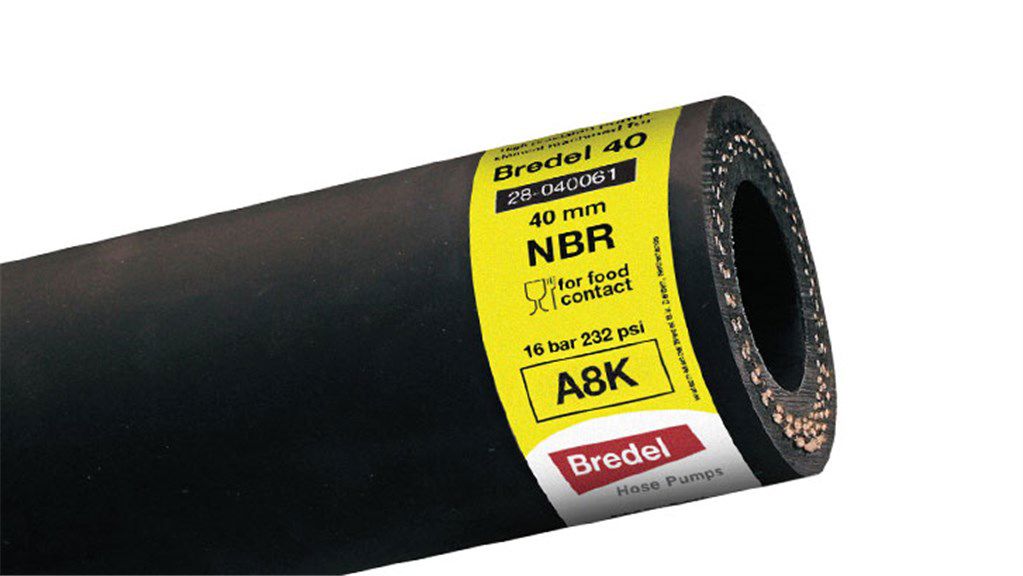

Label codes |

|

A |

Pump type |

|

B |

Re-order number |

|

C |

Bore size |

|

D |

Material of the inner layer |

|

E |

Maximum permitted pressure |

|

F |

Factory code [material; year; month] |

On one end of each hose the factory code [material; year; month] and the batch number are engraved.

Year: last digit (7 = 2017)

Month: A = Jan, E = May

Material: E = F-NBR, M = CSM, NM or NT = NR, P = NBR, S = EPDM

Flow rates to 37 GPM (8500 L/h) and pressures up to 232 psi. Food quality hose compliant.

Pumps - hose pumps

Flow rates to 23.1 GPM (5250 L/h) and pressures up to 232 psi. Paint-free electroplated pump housing.

Pumps - hose pumps

Bioprene hose elements. Meets FDA standards, resistant to alcohols, acids and oxidizing products.

Hose pump elements

NBR (Buna N) hose elements. Resistant to oils, greases, alkalis and detergents.

Hose pump elements

CSM hose elements. Outstanding resistance to strong, oxidizing products and concentrated acids and bases.

Hose pump elements

F-NBR hose elements. Suitable for all food products including oils and greases. Meets FDA, EC and 3A standards.

Hose pump elements

Natural Rubber hose elements. Outstanding abrasion resistance. Generally resistant to diluted acids and alcohols.

Hose pump elements

NBR for Food hose elements. Suitable for a wide range of food products. Resistant to most cleaning chemicals.

Hose pump elements

To order a product or ask a question