EPDM and EPDM plus diaphragms

EPDM diaphragms. Not suitable for use with solvents or petroleum agents. Parylene surface treated version available.

Valves - diaphragms

Call +1 800 282 8823

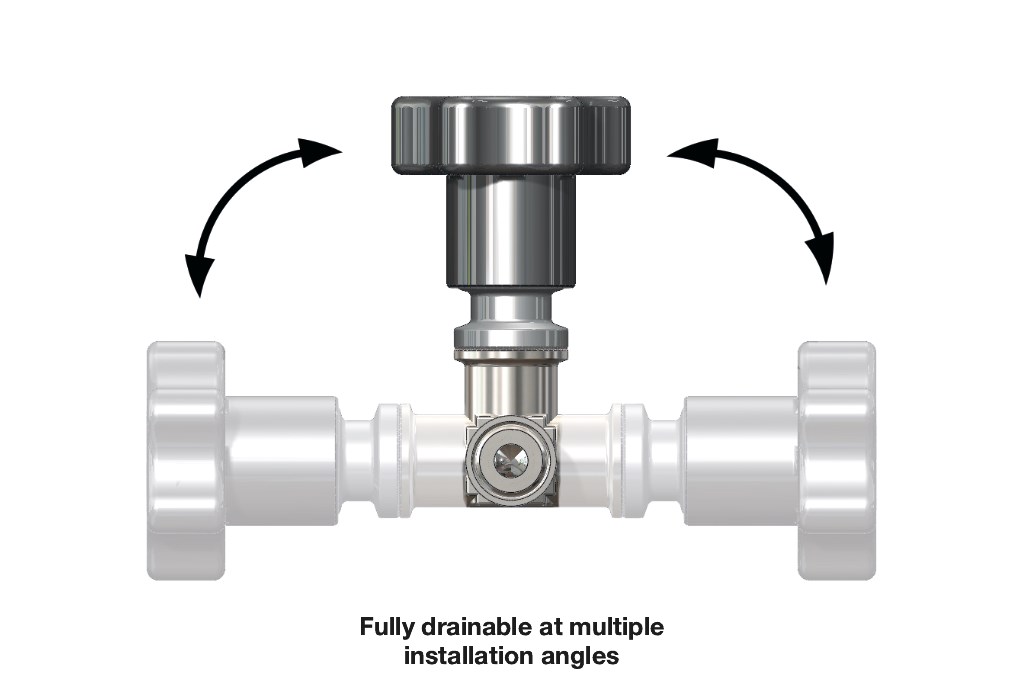

With accelerated diaphragm change over and easy maintenance, the new weirless in-line valve series from ASEPCO valves has been developed with time and cost savings in mind.

Composed of a forged body, the in-line valve is designed to provide a less restrictive fluid path over traditional weir style valves. The weirless in-line valve also eliminates the potential of trapping impurities through our innovative shoulder seal design.

Every surface material that touches your process fluid is manufactured to comply with multiple global industry standards, safeguarding you and your process.

| Mounting type | Clamp, Weld-in |

| Max. operating pressure | 10 bar |

| Max. operating pressure | 150 psi |

| Compatible actuators | Fail closed, Manual, Pneumatic |

| Compatible diaphragms | EPDM, EPDM plus, Silicone |

| Surface finish options | Electropolished, Inner: Max. 15 µin Ra (0.38 µm), Outer: Max. 32 µin Ra (0.8 µm) |

| Certification | ISO 9001 |

| Standards | ASME BPE, ASME BPVC, CE-PED |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

| Performance | |||

|---|---|---|---|

| Cv (gpm) | Kv (m3/h) Kv = .865Cv |

||

| ASME BPE | 0.5" | 2.94 | 2.54 |

| 0.75" | 8.00 | 6.92 | |

| 1" | 16.96 | 14.67 | |

| 1.5" | 43.78 | 37.87 | |

| DIN 11866 DIN 32676 Series A | DN 10 A | 2.94 | 2.54 |

| DN 15 A | 8.00 | 6.92 | |

| Inline valves | |

|---|---|

| Mounting type | Clamp, Weld-in |

| Flow rate (Cv) | 2.94 - 43.78 gpm |

| Flow rate (Kv) | 2.54 - 37.87 m³/h |

| Mounting sizes | 0.5", 0.75", 1.0", 1.5", DN 10 A, DN 15 A |

| Max. operating pressure | 10 bar |

| Max. operating pressure | 150 psi |

| Operating temperature range | -35 to 135 °C |

| Operating temperature range | -30 to 275 °F |

| Compatible actuators | Fail closed, Manual, Pneumatic |

| Compatible diaphragms | EPDM, EPDM plus, Silicone |

| Surface finish options | Electropolished, Inner: Max. 15 µin Ra (0.38 µm), Outer: Max. 32 µin Ra (0.8 µm) |

| Certification | ISO 9001 |

| Standards | ASME BPE, ASME BPVC, CE-PED |

| Weight | 0.12 - 1.1 kg |

| Weight | 0.27 - 2.43 lbs |

| Dimensions | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Size | A mm (inch) | L mm (inch) | L2 mm (inch) | B - with manual actuator mm (inch) | B - with pneumatic actuator mm (inch) | C - with manual actuator mm (inch) | D - with pneumatic actuator mm (inch) | E - with pneumatic actuator mm (inch) | |

| ASME BPE | 0.5" | 63.5 (2.5) | 81.0 (3.19) | 20.1 (0.79) | 66.4 (2.6) | 45.7 (1.8) | 100.5 (4.0) | 149.9 (5.9) | 149.9 (5.9) |

| 0.5" | 101.6 (4.0) | 104.8 (4.13) | 20.4 (0.80) | 66.4 (2.6) | 85.8 (3.4) | 100.5 (4.0) | 170.0 (6.7) | 170.0 (6.7) | |

| 1" | 114.3 (4.5) | 114.3 (4.5) | 20.7 (0.81) | 66.4 (2.6) | 85.8 (3.4) | 119.7 (4.7) | 189.4 (7.5) | 189.4 (7.5) | |

| 1.5" | 139.7 (5.5) | 139.7 (5.5) | 22.2 (0.87) | 66.4 (2.6) | 105.0 (4.1) | 126.0 (5.0) | 207.5 (8.2) | 207.5 (8.2) | |

DIN 11866 DIN 32676 Series A |

DN 10 A | 108.0 (4.25) | 108.0 (4.25) | 33.6 (1.32) | 66.4 (2.6) | 45.7 (1.8) | 101.0 (4.0) | 150.0 (5.9) | 150.0 (5.9) |

| DN 15 A | 108.0 (4.25) | 108.0 (4.25) | 21.9 (0.86) | 66.4 (2.6) | 85.8 (3.4) | 101.0 (4.0) | 170.5 (6.7) | 170.5 (6.7) | |

| C, D and E dimension shown when valve is in closed position All dimensions are for reference only | |||||||||

| Valve body weight | Assembly weight | |||||||

|---|---|---|---|---|---|---|---|---|

| Size | Connection | lbs | kg | Weight with manual actuator (lbs) | Weight with manual actuator (kg) | Weight with pneumatic actuator (lbs) | Weight with pneumatic actuator (kg) | |

| ASME BPE | 0.5" | Clamp-end | 0.30 | 0.13 | 1.5 | 0.67 | 1.7 | 0.76 |

| 0.5" | Weld-end | 0.27 | 0.12 | 1.4 | 0.65 | 1.6 | 0.75 | |

| 0.75" | Clamp-end | 0.64 | 0.29 | 2.1 | 0.97 | 3.1 | 1.41 | |

| 0.75" | Weld-end | 0.62 | 0.28 | 2.1 | 0.96 | 3.1 | 1.40 | |

| 1" | Clamp-end | 1.36 | 0.62 | 3.5 | 1.58 | 4.4 | 2.02 | |

| 1" | Weld-end | 1.13 | 0.51 | 3.2 | 1.47 | 4.2 | 1.91 | |

| 1.5" | Clamp-end | 2.53 | 1.15 | 7.2 | 3.25 | 9.3 | 4.22 | |

| 1.5" | Weld-end | 2.43 | 1.10 | 7.1 | 3.20 | 9.2 | 4.17 | |

DIN 11866 DIN 32676 Series A |

DN 10 A | Clamp-end | 0.47 | 0.21 | 1.6 | 0.75 | 1.8 | 0.84 |

| DN 10 A | Weld-end | 0.27 | 0.12 | 1.4 | 0.65 | 1.6 | 0.75 | |

| DN 15 A | Clamp-end | 0.80 | 0.36 | 2.3 | 1.04 | 3.3 | 1.48 | |

| DN 15 A | Weld-end | 0.61 | 0.28 | 2.1 | 0.96 | 3.1 | 1.40 | |

| Material | Stainless steel 316L |

Available in silicone, EPDM and EPDM plus Extensively tested to ensure long service life Patented, leak-free static shoulder seal High performance with minimal maintenance

EPDM diaphragms. Not suitable for use with solvents or petroleum agents. Parylene surface treated version available.

Valves - diaphragms

Valve diaphragms. Medical grade silicone available in white or clear finish. Parylene surface treated version available.

Valves - diaphragms

Excellent heat and chemical resistance. Not suitable for use with ketones and esters. Steam resistant version available.

Valves - diaphragms

Durable, easy to maintain pneumatic actuators made of a plastic housing and stainless steel diaphragm interface.

Valves - actuators

Eliminate the usual dead leg between seal points, in a reliable block-and-bleed valve.

Valves - inline valves

Minimize hold-up volume, with two flow paths in one efficient valve.

Valves - inline valves

To order a product or ask a question