NBR (Buna N) hose

NBR (Buna N) hose elements. Resistant to oils, greases, alkalis and detergents.

Hose pump elements

Call +63 2 295 6392

Bredel hose pumps have no valves or seals to leak, clog or replace and provide flow rates to 108,000 L/h and pressures to 16 bar.

They can pump viscous and abrasive slurries, pastes and sludge, with up to 80 % solids in suspension.

Unlike other pump types, the highly abrasive nature of grit-filled sludge or lime slurry in the environmental market, does not affect peristaltic hose pump life.

Bredel hose pumps eliminate ancillary equipment such as dry run protection, seal water flush systems and in-line check valves. They are also reversible to flush lines.

| Max. flow rate continuous | 72000 L/h |

| Max. flow rate continuous | 18997 USGPH |

| Volume per revolution | 6.7 - 40 L |

| Max. continuous operating speed | 30 - 50 rpm |

| Max. operating pressure | 16 bar |

| Max. operating pressure | 232 psi |

| Min. starting torque | 1150 - 5,300 N m |

| Min. starting torque | 10178 - 46,908 in.lbs |

| Weight | 558 - 5,985 kg |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

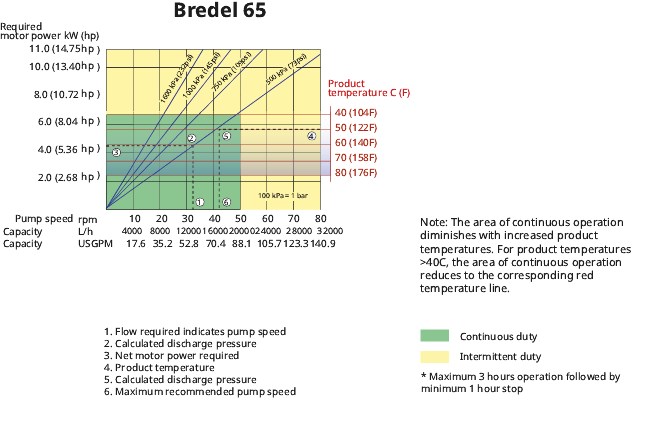

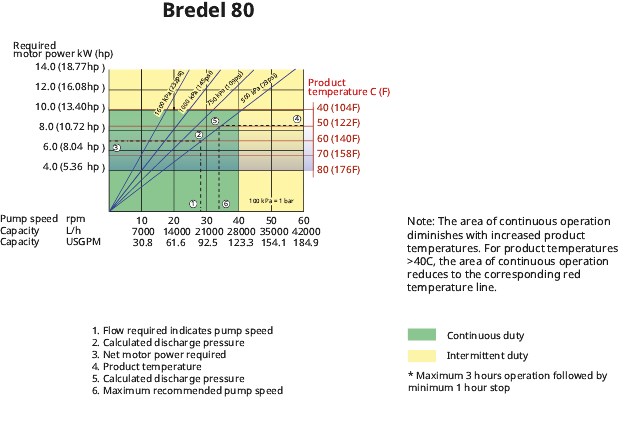

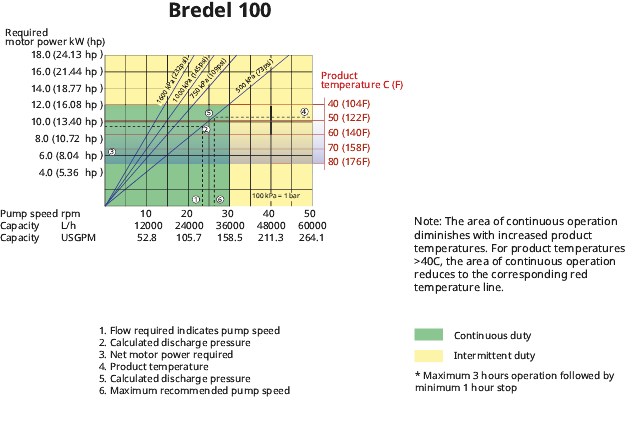

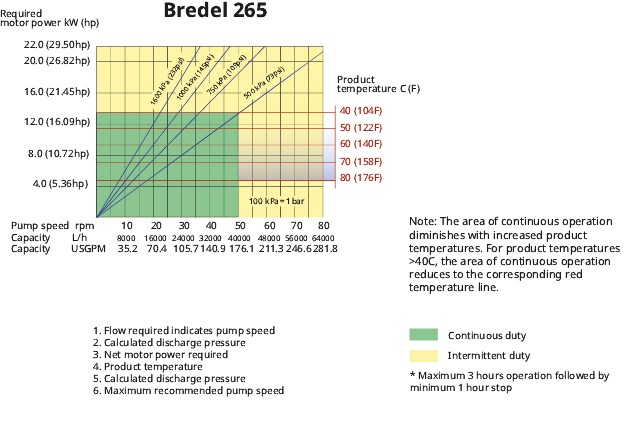

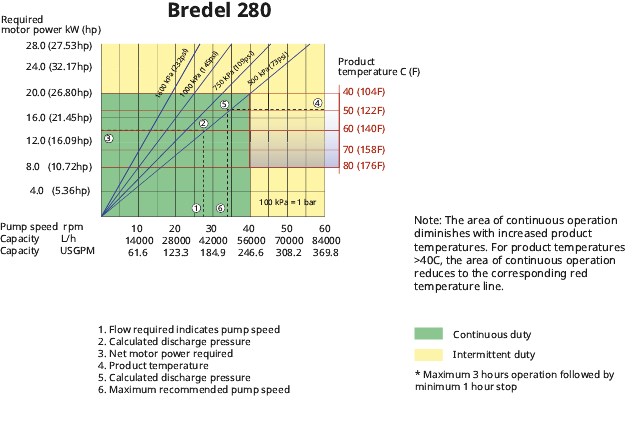

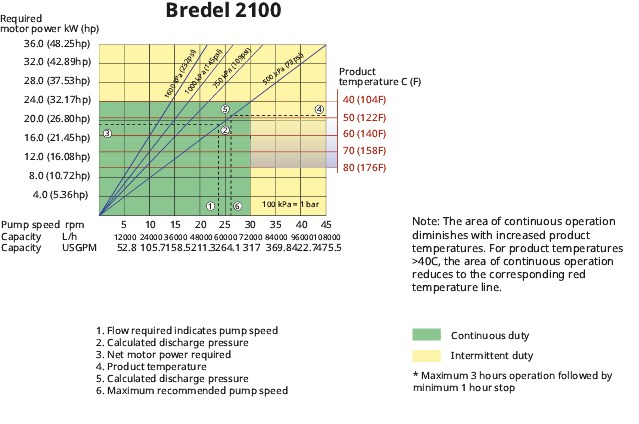

| Bredel 65 | Bredel 80 | Bredel 100 | Bredel 265 | Bredel 280 | Bredel 2100 | |

|---|---|---|---|---|---|---|

| Max. flow rate continuous | 20100 L/h | 28080 L/h | 36000 L/h | 40200 L/h | 56160 L/h | 72000 L/h |

| Max. flow rate continuous | 5303 USGPH | 7409 USGPH | 9499 USGPH | 10607 USGPH | 14818 USGPH | 18997 USGPH |

| Max. flow rate intermittent | 32160 L/h | 42120 L/h | 60000 L/h | 64320 L/h | 84240 L/h | 108000 L/h |

| Max. flow rate intermittent | 8485 USGPH | 11113 USGPH | 15831 USGPH | 16971 USGPH | 22227 USGPH | 28496 USGPH |

| Volume per revolution | 6.7 L | 11.7 L | 20 L | 13.4 L | 23.4 L | 40 L |

| Volume per revolution | 1.77 USG | 3.09 USG | 5.28 USG | 3.54 USG | 6.18 USG | 10.57 USG |

| Max. continuous operating speed | 50 rpm | 40 rpm | 30 rpm | 50 rpm | 40 rpm | 30 rpm |

| Max. intermittent operating speed | 80 rpm | 60 rpm | 50 rpm | 80 rpm | 60 rpm | 45 rpm |

| Max. operating pressure | 16 bar | 16 bar | 16 bar | 16 bar | 16 bar | 16 bar |

| Max. operating pressure | 232 psi | 232 psi | 232 psi | 232 psi | 232 psi | 232 psi |

| Max. inlet pressure | 2 bar abs | 1.5 bar abs | 1.5 bar abs | 2 bar abs | 1.5 bar abs | 1.5 bar abs |

| Max. inlet pressure | 30 psi abs | 23 psi abs | 23 psi abs | 30 psi abs | 23 psi abs | 23 psi abs |

| Max. suction capability | 9.5 mWC | 9 mWC | 7 mWC | |||

| Max. suction capability | 374 inWC | 354 inWC | 276 inWC | |||

| Suction capability (80% Flow rate) | 8 mWC | 7 mWC | 5 mWC | |||

| Suction capability (80% Flow rate) | 315 inWC | 276 inWC | 197 inWC | |||

| Operating temperature range | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C |

| Operating temperature range | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F |

| Fluid temperature range | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C |

| Fluid temperature range | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F |

| Min. starting torque | 1150 N m | 2000 N m | 3100 N m | 2000 N m | 3400 N m | 5300 N m |

| Min. starting torque | 10178 in.lbs | 17701 in.lbs | 27437 in.lbs | 17701.5 in.lbs | 30092 in.lbs | 46908 in.lbs |

| Weight | 558 kg | 930 kg | 1300 kg | 2780 kg | 4295 kg | 5985 kg |

| Weight | 1230 lbs | 2050 lbs | 2866 lbs | 6129 lbs | 9469 lbs | 13195 lbs |

| Hose lubricant required | 20 L | 40 L | 60 L | 40 L | 80 L | 120 L |

| Hose lubricant required | 5.28 USG | 10.57 USG | 15.85 USG | 10.57 USG | 21.13 USG | 31.7 USG |

| Port configurations | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up |

| Compatible hose materials | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer |

| Flange assembly type | ANSI, DIN, JIS | ANSI, DIN, JIS | ANSI, DIN, JIS | ANSI, DIN, JIS | ANSI, DIN, JIS | ANSI, DIN, JIS |

| Type | A | B | C | D | E | F | G | H | H1 | J | K | Lmax | L1 | L2max | M | N | O | ØP | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 65 (mm) | 1059 | 580 | 3 | 746 | 152 | 680 | 740 | 1036 | 525 | 104 | 137 | 1172 | 141 | 486 | 415 | 220 | 50 | 18 | 18 | 145 | 4 |

| Bredel 65 (inches) | 41.7 | 22.8 | 0.12 | 29.4 | 6 | 26.8 | 29.1 | 40.8 | 20.7 | 4.1 | 5.4 | 46.1 | 5.6 | 19.1 | 16.3 | 8.7 | 2 | 0.71 | 0.71 | 5.7 | 0.16 |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| Bredel 65 | 2.5" | 65mm | 65mm |

| Type | A | B | C | D | E | F | G | H | H1 | J | K | Lmax | L1 | L2max | M | N | O | ØP | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 80 (mm) | 1257 | 700 | 4 | 876 | 182 | 900 | 990 | 1218 | 620 | 124 | 153 | 1351 | 166 | 582 | 525 | 275 | 50 | 22 | 18 | 160 | 8 |

| Bredel 80 (inches) | 49.5 | 27.6 | 0.16 | 34.5 | 7.2 | 35.4 | 39 | 48 | 24.4 | 4.9 | 6 | 53.2 | 6.5 | 22.9 | 20.7 | 10.8 | 2 | 0.9 | 0.71 | 6.3 | 0.31 |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| Bredel 80 | 3" | 80mm | 80mm |

| Type | A | B | C | D | E | F | G | H | H1 | J | K | Lmax | L1 | L2max | M | N | O | ØP | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 100 (mm) | 1468 | 813 | 3 | 1042 | 199 | 1050 | 1140 | 1415 | 720 | 151 | 173 | 1392 | 200 | 489 | 540 | 310 | 50 | 22 | 18 | 180 | 8 |

| Bredel 100 (inches) | 57.8 | 32 | 0.12 | 41 | 7.8 | 41.3 | 44.9 | 55.7 | 28.3 | 5.9 | 6.8 | 54.8 | 7.9 | 19.3 | 21.3 | 12.2 | 2 | 0.9 | 0.71 | 7.1 | 0.31 |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| Bredel 100 | 4" | 100mm | 100mm |

| Type | A1 | A2 | B | C | D | E | F | G | H | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 265 (mm) | * | 1115 | 580 | 3 | 746 | 152 | 720 | 943 | 1036 | 18 | 145 | 4 |

| Bredel 265 (inches) | * | 43.9 | 22.8 | 0.12 | 29.4 | 5.99 | 28.3 | 37.1 | 40.8 | 0.71 | 5.7 | 0.16 |

| Type | A1 | A2 | B | C | D | E | F | G | H | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 280 (mm) | * | 1404 | 700 | 4 | 876 | 182 | 800 | 1047 | 1218 | 18 | 160 | 8 |

| Bredel 280 (inches) | * | 55.3 | 27.6 | 0.16 | 34.5 | 7.2 | 31.5 | 41.2 | 48 | 0.71 | 6.3 | 0.31 |

| Type | A1 | A2 | B | C | D | E | F | G | H | ØQ | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel 2100 (mm) | * | 1516 | 813 | 3 | 1042 | 199 | 916 | 1218 | 1415 | 18 | 180 | 8 |

| Bredel 2100 (inches) | * | 59.7 | 32 | 0.12 | 41 | 7.8 | 36.1 | 48 | 55.7 | 0.71 | 7.1 | 0.31 |

| Hose material | CSM, EPDM, F-NBR, NBR, NBR for food, NR-Metering, NR-Transfer |

| Housing | Cast iron, ISO12944 category C4M |

| Rotor assembly | Cast iron, ISO12944 category C4M |

| Cover assembly | Cast iron, ISO12944 category C4M |

| Brackets and fasteners | Galvanised steel, Stainless steel 316 |

| Support frame | Galvanised steel, Stainless steel 316 |

| Hose clamps | Galvanised steel, Stainless steel 316 |

| Seals | Neoprene, Nitrile |

NBR (Buna N) hose elements. Resistant to oils, greases, alkalis and detergents.

Hose pump elements

EPDM hose elements. Excellent chemical resistance, especially to ketones, alcohols and concentrated acids.

Hose pump elements

Flow rates to 17,520 L/h (4,623 USGPH) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

Flow rates to 6,200 L/h (27.3 USGPM) and pressures up to 8 bar (116 psi). Optimised for process uptime.

Pumps - hose pumps

Flow rates to 5,250 L/h (23.1 USGPM) and pressures up to 16 bar (232 psi). Paint-free electroplated pump housing.

Pumps - hose pumps

To order a product or ask a question