CSM hose

CSM hose elements. Outstanding resistance to strong, oxidising products and concentrated acids and bases.

Hose pump elements

Call +27 11 796 2960

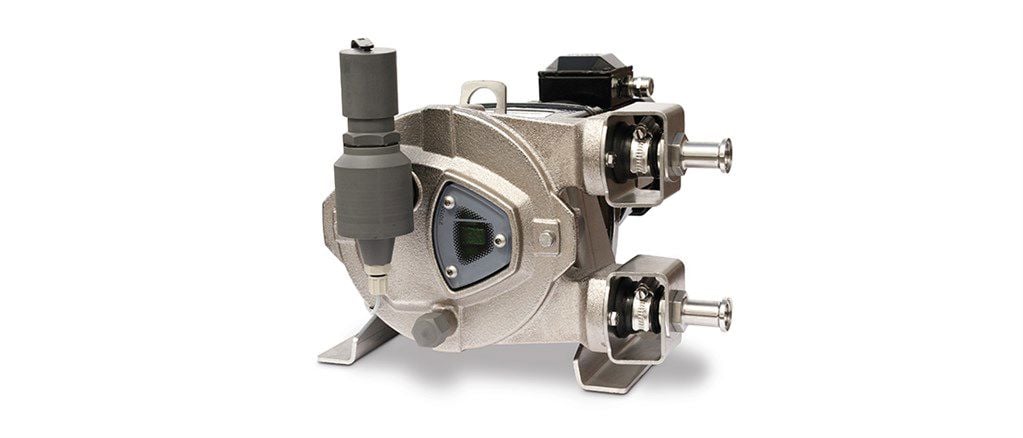

Bredel DuCoNite® pumps with a paint-free electroplated housing which protects against corrosive and caustic fluids and atmospheres. The DuCoNite® pump is used for the most challenging applications. A high-tech surface protection method has rendered the pump ultra-resistant to aggressive liquids. The DuCoNite® hose pumps are available in five pump sizes - with capacities up to 5,250 L/h and pressures up to 16 bar.

The DuCoNite® hose pump reliably handles a variety of harsh materials, such as sodium hypochlorite, titanium dioxide, sodium hydroxide, catalytic agents, sulfuric acid, lime slurry, acidic liquids, solvents and resins.

| Max. flow rate continuous | 3200 L/h |

| Max. flow rate continuous | 844 USGPH |

| Volume per revolution | 0.022 - 0.625 L |

| Max. continuous operating speed | 65 - 100 rpm |

| Max. operating pressure | 16 bar |

| Max. operating pressure | 232 psi |

| Min. starting torque | 47 - 210 N m |

| Min. starting torque | 416 - 1,859 in.lbs |

| Weight | 30 - 130 kg |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| DuCoNite10 | DuCoNite15 | DuCoNite20 | DuCoNite25 | DuCoNite32 | |

|---|---|---|---|---|---|

| Max. flow rate continuous | 105 L/h | 375 L/h | 600 L/h | 1800 L/h | 3200 L/h |

| Max. flow rate continuous | 28 USGPH | 99 USGPH | 158 USGPH | 475 USGPH | 844 USGPH |

| Max. flow rate intermittent | 160 L/h | 525 L/h | 820 L/h | 2740 L/h | 5250 L/h |

| Max. flow rate intermittent | 42 USGPH | 139 USGPH | 216 USGPH | 723 USGPH | 1385 USGPH |

| Volume per revolution | 0.022 L | 0.083 L | 0.152 L | 0.3 L | 0.625 L |

| Volume per revolution | 0.0058 USG | 0.0219 USG | 0.0402 USG | 0.079 USG | 0.165 USG |

| Max. continuous operating speed | 80 rpm | 75 rpm | 65 rpm | 100 rpm | 86 rpm |

| Max. intermittent operating speed | 120 rpm | 105 rpm | 90 rpm | 155 rpm | 140 rpm |

| Max. operating pressure | 12 bar | 12 bar | 10 bar | 16 bar | 16 bar |

| Max. operating pressure | 174 psi | 174 psi | 145 psi | 232 psi | 232 psi |

| Suction pressure | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs |

| Suction pressure | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs |

| Max. inlet pressure | 2 bar abs | 2 bar abs | 2 bar abs | 3.5 bar abs | 3 bar abs |

| Max. inlet pressure | 30 psi abs | 30 psi abs | 30 psi abs | 51 psi abs | 44 psi abs |

| Max. suction capability | 9.5 mWC | 9.5 mWC | 9.5 mWC | 9.5 mWC | 9.5 mWC |

| Max. suction capability | 374 inWC | 374 inWC | 374 inWC | 374 inWC | 374 inWC |

| Operating temperature range | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C | -20 °C to 45 °C |

| Operating temperature range | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F | -4 °F to 113 °F |

| Fluid temperature range | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C | -20 °C to 80 °C |

| Fluid temperature range | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F | -4 °F to 176 °F |

| Min. starting torque | 47 N m | 60 N m | 85 N m | 115 N m | 210 N m |

| Min. starting torque | 416 in.lbs | 531 in.lbs | 752 in.lbs | 1018 in.lbs | 1859 in.lbs |

| Weight | 30 kg | 45 kg | 45 kg | 90 kg | 130 kg |

| Weight | 66 lbs | 99 lbs | 99 lbs | 198 lbs | 287 lbs |

| Hose lubricant required | 0.5 L | 1 L | 1 L | 2.5 L | 4.5 L |

| Hose lubricant required | 0.13 USG | 0.26 USG | 0.26 USG | 0.66 USG | 1.19 USG |

| Port configurations | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up |

| Compatible hose materials | CSM, EPDM, F-NBR, NBR, NBR for food, NR, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NBR for food, NR, NR-Metering, NR-Transfer |

| Flange assembly type | ANSI, DIN | ANSI, DIN | ANSI, DIN | ANSI, DIN | ANSI, DIN |

| Type | A | A1 | B | C | D | ØE | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuCoNite 10 (mm) | 337 | 311 | 171 | 62 | 116 | 16 | 235 | 265 | 225 | 127 | 254 | 78 | 51 | 501 | 46 | 378 | 150 | 65 | 25 | 12 |

| DuCoNite 10 (inches) | 13.3 | 12.2 | 6.7 | 2.44 | 4.6 | 16mm | 9.3 | 10.4 | 8.9 | 5.0 | 10.0 | 3.1 | 2 | 19.7 | 1.8 | 14.9 | 5.9 | 2.6 | 1.0 | 12mm |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| DuCoNite 10 | 0.5” | 10mm | 10mm |

| Type | A | A1 | B | C | D | ØE | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuCoNite 15 (mm) | 427 | 431 | 230 | 63 | 195 | 20 | 285 | 315 | 304 | 167 | 294 | 82 | 61 | 505 | 46 | 378 | 150 | 75 | 25 | 12 |

| DuCoNite 15 (inches) | 16.8 | 17.0 | 9.1 | 2.5 | 7.7 | 20mm | 11.2 | 12.4 | 12.0 | 6.6 | 11.6 | 3.2 | 2.4 | 19.9 | 1.8 | 14.9 | 5.9 | 3.0 | 1.0 | 12mm |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| DuCoNite 15 | 0.75” | 20mm | 20mm |

| Type | A | A1 | B | C | D | ØE | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuCoNite 20 (mm) | 427 | 431 | 230 | 63 | 195 | 20 | 285 | 315 | 304 | 167 | 294 | 82 | 61 | 505 | 46 | 378 | 150 | 75 | 25 | 12 |

| DuCoNite 20 (inches) | 16.8 | 17.0 | 9.1 | 2.5 | 7.7 | 20mm | 11.2 | 12.4 | 12.0 | 6.6 | 11.6 | 3.2 | 2.4 | 19.9 | 1.8 | 14.9 | 5.9 | 3.0 | 1.0 | 12mm |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| DuCoNite 20 | 0.75” | 20mm | 20mm |

| Type | A | B | C | D | E | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP | ØQ | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuCoNite 25 (mm) | 521 | 304 | 2.5 | 264 | 98 | 279 | 315 | 460 | 222 | 359 | 66 | 97 | 592 | 58 | 468 | 305 | 120 | 15 | 12 | 14 | 85 |

| DuCoNite 25 (inches) | 20.5 | 12 | 0.09 | 10.4 | 3.9 | 11 | 12.4 | 18.1 | 8.7 | 14.1 | 2.6 | 3.8 | 23.3 | 2.3 | 18.4 | 12 | 4.7 | 0.6 | 0.47 | 0.6 | 3.3 |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| DuCoNite 25 | 1" | 25mm | 25mm |

| Type | A | B | C | D | E | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP | ØQ | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DuCoNite 32 (mm) | 631 | 375 | 2.5 | 330 | 105 | 324 | 360 | 538 | 260 | 402 | 72 | 93 | 684 | 68 | 544 | 370 | 120 | 20 | 12 | 18 | 100 |

| DuCoNite 32 (inches) | 24.8 | 14.8 | 0.09 | 13 | 4.1 | 12.8 | 14.2 | 21.2 | 10.2 | 15.8 | 2.8 | 3.7 | 26.9 | 2.7 | 21.4 | 14.6 | 4.7 | 0.79 | 0.47 | 0.71 | 3.94 |

| Connector sizes | ANSI 150# | EN DIN | JIS |

|---|---|---|---|

| DuCoNite 32 | 1.25"/1.5" | 32mm | 32mm |

| Hose material | CSM, EPDM, F-NBR, Natural rubber (NR), NBR, NBR for food, NR-Metering, NR-Transfer |

| Housing | Cast iron with DuCoNite surface treatment |

| Rotor assembly | Cast iron with DuCoNite surface treatment |

| Cover assembly | Cast iron with DuCoNite surface treatment |

| Brackets and fasteners | Stainless steel 316 |

| Support frame | Stainless steel 316 |

| Hose clamps | Stainless steel 316 |

| Coupling bush | Alloy steel |

| Seals | EPDM, Viton® |

CSM hose elements. Outstanding resistance to strong, oxidising products and concentrated acids and bases.

Hose pump elements

NBR (Buna N) hose elements. Resistant to oils, greases, alkalis and detergents.

Hose pump elements

EPDM hose elements. Excellent chemical resistance, especially to ketones, alcohols and concentrated acids.

Hose pump elements

Flow rates to 6,200 L/h (27.3 USGPM) and pressures up to 8 bar (116 psi). Optimised for process uptime.

Pumps - hose pumps

Flow rates to 17,520 L/h (4,623 USGPH) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

Flow rates to 108,000 L/h (475 GPM) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

To order a product or ask a question