Understanding the technology

Centrifugal pumps are one of the most common machines in the industrial landscape. The technology relies on two central components: an impeller, and a volute casing which contains the impeller and the cased fluid.

The pumps are available in a wide variety of sizes. Axial centrifugal pumps in municipal water applications can be very large, whereas they can be small and compact in domestic systems.

The basics of how they work

Fluid enters the pump through an inlet positioned at the center of the impeller, or the 'suction eye'. Friction between the liquid and the surface of the rotating impeller causes the fluid to rotate. The rotating fluid is then thrown to the outside of the impeller by centrifugal force. It is this phenomenon that causes objects revolving around a center point to move away from the center. This is how the fluid gains kinetic energy.

The amount of energy added to the fluid is dependent on three factors; the density of the liquid, the impellers speed of rotation; and the diameter of the impeller.

From the impeller, the liquid is released into the chamber of the volute casing and directed to the discharge outlet, and ultimately into the system.

The pump design allows for high flow rates with low pressure. The design also creates a pulseless flow which makes them well suited to continuous pumping duties.

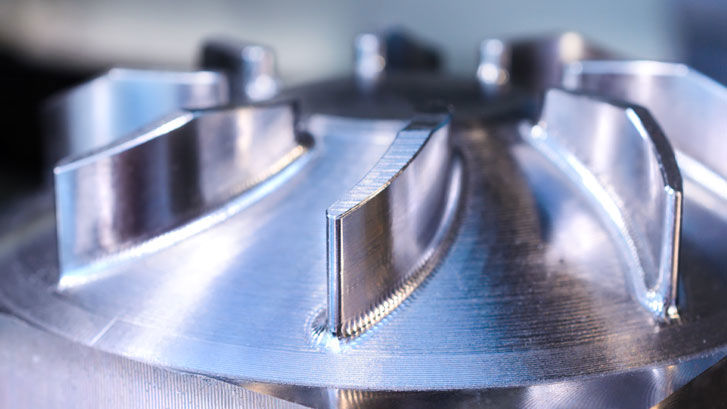

A common misconception is that the curvature of an impellers vanes help to move fluid by trapping and pushing it through the pump. In reality, the vanes purpose is to conduct the liquid across the smoothest possible path as it travels through the pump. Backwards curved vanes, for example, help to stabilize flow conditions at high speeds and reduce demands on the motor of the pump. It is, therefore, possible to tell the correct rotation of an impeller by looking at the curvature of the vanes.

Challenges of centrifugal pumps

It is important to add that, because of the way centrifugal pumps impart energy onto the fluid, the pump must be fully submerged and in direct contact with the pumped fluid.

A centrifugal pump will not pump air and is unable to impart suction. Therefore, before the pumps are switched on, they need to be primed. Likewise, during operation, there must be under positive pressure as the pump can not run dry and should not be used in applications that require suction lift. In the event of there being insufficient fluid, not only will performance be affected, but the pump will run into cavitation and soon fail, typically irreparably.

- In critical suction conditions, the pumps cannot dry run

- Fixed speed and limited speed control

- Impeller typically requires a complex mechanical seal

- Struggles with abrasive and materials with a high viscosity

The pump's design is also complex compared to other pump types—such as peristaltic pumps—and requires skilled staff for maintenance and changing seals.

Related articles

-

Case Study

![]()

High suction pumps reduce yeast harvesting time

The average yeast harvest time for one yeast strain was reduced by 56%.

Case Study

-

Case Study

![]()

Bredel hose pumps transfer abrasive slurry 24/7 at aluminum salt slag recovery plant

RVA, a France-based company that specializes in the recovery of salt slag, a by-product of...

Case Study

The world leader in peristaltic pump manufacture and associated fluid path technologies

To order a product or ask a question call +1 800 282 8823 or