- Case Study

Emmi is the leading manufacturer of high-quality dairy products in Switzerland. At its Dagmersellen location in the canton of Lucerne, Emmi produces milk powder and cheeses such as mozzarella, ricotta, and cottage cheese.

Modernization of production

As part of an ambitious sustainability strategy, Emmi has set itself the goal of using raw materials as efficiently as possible to reduce food losses to an absolute minimum. In the course of mozzerella production line moderinisation, the focus was on the transfer of the cheese-curd-whey mixture from the cheese vat to the drain table.

The cheese-curds-whey mixture was washed into tubs by gravity, a process which was both time consuming and labour intensive, so an efficient transfer pump was sought.

Emmi carried out a series of comprehensive tests using a number of pump types including centrifugal, air operated diaphragm alongside other positive displacement pumps, all with the same criteria. Amongst the pumps trialled was a Certa Sine™ pump, a sinusoidal pump from MasoSine.

Goal: Gentle lift pump for maximum product yield

The pump Emmi sought needed to combine the following characteristics:

- Flow rate of approx. 10,000-20,000 liters per hour

- Clean in place (CIP) capability for efficient cleaning

- Low shear pumping of the delicate cheese curds-whey mixture

High shear forces durng transfer can degrade the curds and create excessive cheese fines, which in turn reduces the product yield.

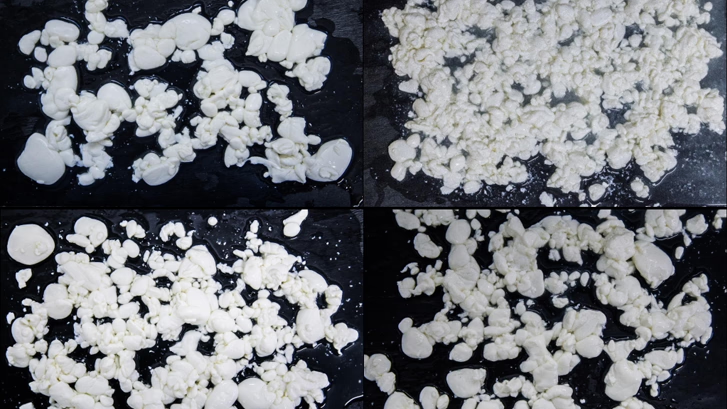

For each pump tested, the fracture condition before and after the pumping process was visually analysed and the whey fat content measured. In order to further quantify the product losses caused by the pumping process, the cheese fines produced in the whey were collected and weighed. Analysis of the pump results quickly revealed significant cheese curd quality differences.

Although purchase costs were lower for some of the pump types tested, the reduction in product yield due to curds and whey degradation using those pumps, quickly convinced Emmi that the Certa Sine pump was superior for their application. The Certa Sine pump 500 model had the lowest fat loss in the whey and the curds remained virtually unchanged after transfer.

Product-friendly sinusoidal principle for high viscosities

Florian Walter, Product Manager at MaoSine commented "The Certa Sine pump design has been specially developed for the most gentle transfer of highly viscous and shear sensitive ingredients in the food and beverage industry".

"The Certa Sine pump design has been specially developed for the most gentle transfer of highly viscous and shear sensitive ingredients in the food and beverage industry".

Lowest total cost of ownership and rapid payback

By increasing cheese yield, the Certa Sine pump trailed at Emmi added extremely low total cost of ownership to the benefits experienced and they consequently chose to use two Certa 500 pumps in the production of their popular mozzarella cheese.

Further reading

-

![]()

Certa Sine pumps

Improve process efficiency and minimize total cost of ownership.

-

Insight

![]()

-

Insight

![]()

New report reveals how to improve dairy production yield

Watson-Marlow Fluid Technology Group (WMFTG) has made available a new report for the dairy sector...

News/Insight

-

Insight

![]()

Choosing the right pump technologies

How choosing the right pumping technologies to make processes more efficient requires an...

News/Insight

The world leader in peristaltic pump manufacture and associated fluid path technologies

To order a product or ask a question call +1 800 282 8823 or