APEX NR hose

Natural Rubber hose element for APEX hose pumps. Generally resistant to diluted acids and alcohols.

Hose pump elements

Call +1 800 282 8823

The newly expanded range of APEX hose pumps is ideal for aggressive and abrasive applications up to 8 bar (116 psi). With their seal-less, valve-less design, APEX pumps are engineered for a more competitive price/performance ratio vs high pressure hose pumps. Designed to suit all dosing, metering and transfer applications with unmatched flow stability from 2.8 to 6,200 L/h.

The APEX pump incorporates Bredel’s long proven direct-coupled technology, delivering the most reliable pump design in a compact footprint. While the APEX gearbox mounts directly to the pump housing, the APEX pump rotor is supported by its own sealed bearing hub, isolating and protecting the gearbox from integral forces.

| Max. flow rate continuous | 5310 L/h |

| Max. flow rate continuous | 1401 USGPH |

| Volume per revolution | 0.046 - 0.74 L |

| Max. continuous operating speed | 100 - 140 rpm |

| Max. operating pressure | 8 bar |

| Max. operating pressure | 116 psi |

| Min. starting torque | 48 - 230 N m |

| Min. starting torque | 425 - 2,040 in.lbs |

| Weight | 40 - 140 kg |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

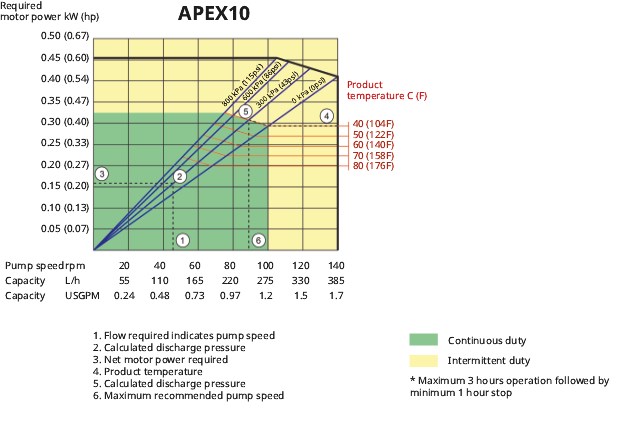

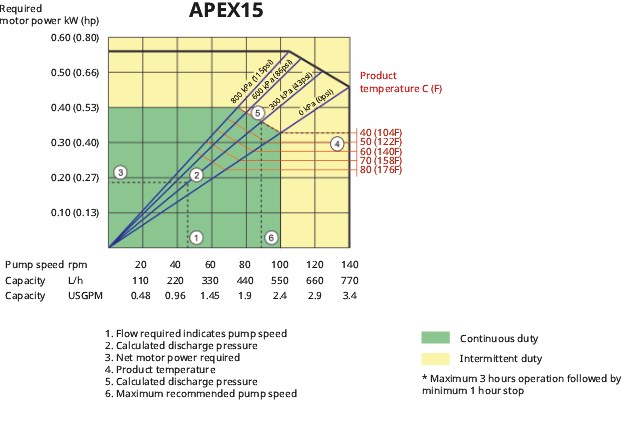

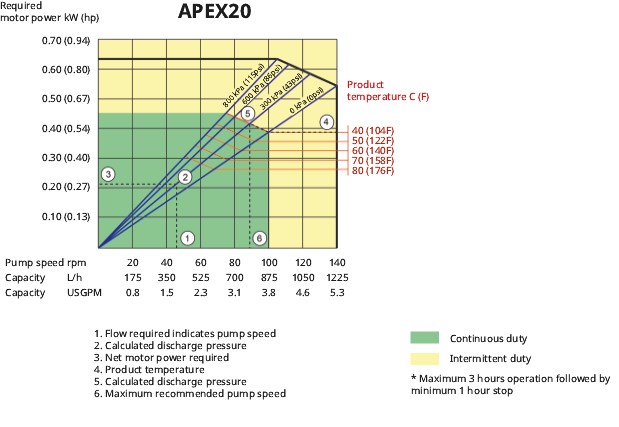

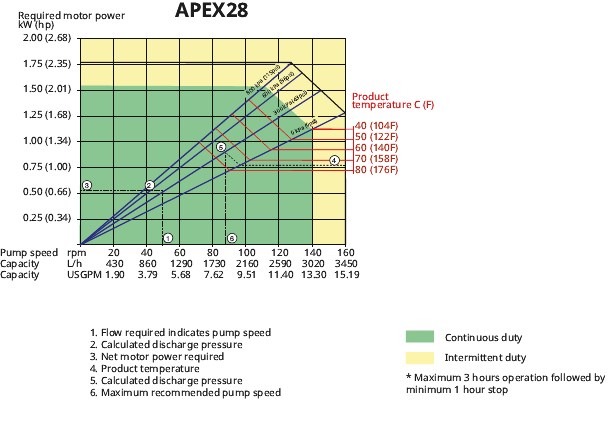

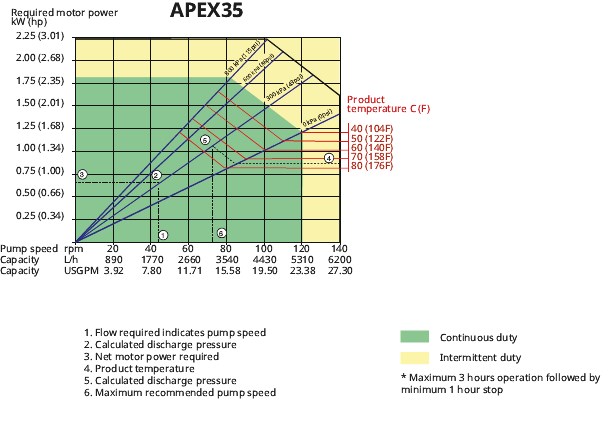

| APEX10 | APEX15 | APEX20 | APEX28 | APEX35 | |

|---|---|---|---|---|---|

| Max. flow rate continuous | 275 L/h | 550 L/h | 875 L/h | 3020 L/h | 5310 L/h |

| Max. flow rate continuous | 73 USGPH | 145 USGPH | 231 USGPH | 797 USGPH | 1401 USGPH |

| Max. flow rate intermittent | 385 L/h | 770 L/h | 1225 L/h | 3450 L/h | 6200 L/h |

| Max. flow rate intermittent | 102 USGPH | 203 USGPH | 323 USGPH | 910 USGPH | 1636 USGPH |

| Volume per revolution | 0.046 L | 0.091 L | 0.145 L | 0.36 L | 0.74 L |

| Volume per revolution | 0.0122 USG | 0.024 USG | 0.038 USG | 0.095 USG | 0.195 USG |

| Max. continuous operating speed | 100 rpm | 100 rpm | 100 rpm | 140 rpm | 120 rpm |

| Max. intermittent operating speed | 140 rpm | 140 rpm | 140 rpm | 160 rpm | 140 rpm |

| Max. operating pressure | 8 bar | 8 bar | 8 bar | 8 bar | 8 bar |

| Max. operating pressure | 116 psi | 116 psi | 116 psi | 116 psi | 116 psi |

| Suction pressure | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs | 0.05 bar abs |

| Suction pressure | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs | 0.73 psi abs |

| Max. inlet pressure | 2 bar abs | 2 bar abs | 2 bar abs | 2.5 bar abs | 2.5 bar abs |

| Max. inlet pressure | 30 psi abs | 30 psi abs | 30 psi abs | 37 psi abs | 37 psi abs |

| Operating temperature range | -20 to 45 °C | -20 to 45 °C | -20 to 45 °C | -20 to 45 °C | -20 to 45 °C |

| Operating temperature range | -4 to 113 °F | -4 to 113 °F | -4 to 113 °F | -4 to 113 °F | -4 to 113 °F |

| Fluid temperature range | -20 to 80 °C | -20 to 80 °C | -20 to 80 °C | -20 to 80 °C | -20 to 80 °C |

| Fluid temperature range | -4 to 176 °F | -4 to 176 °F | -4 to 176 °F | -4 to 176 °F | -4 to 176 °F |

| Min. starting torque | 48 N m | 57 N m | 57 N m | 150 N m | 230 N m |

| Min. starting torque | 425 in.lbs | 505 in.lbs | 505 in.lbs | 1330 in.lbs | 2040 in.lbs |

| Weight | 40 kg | 40 kg | 40 kg | 100 kg | 140 kg |

| Weight | 88 lbs | 88 lbs | 88 lbs | 220 lbs | 309 lbs |

| Hose lubricant required | 1 L | 1 L | 1 L | 2 L | 4 L |

| Hose lubricant required | 0.26 USG | 0.26 USG | 0.26 USG | 0.53 USG | 1.05 USG |

| Port configurations | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up | Down, Left, Right, Up |

| Compatible hose materials | CSM, EPDM, F-NBR, NBR, NBR for food, NR | CSM, EPDM, F-NBR, NBR, NBR for food, NR | CSM, EPDM, F-NBR, NBR, NBR for food, NR | EPDM, NBR, NBR for food, NR | EPDM, NBR, NBR for food, NR |

| Flange assembly type | ANSI, DIN | ANSI, DIN | ANSI, DIN | ANSI, DIN, JIS | ANSI, DIN, JIS |

| A | A1 | B | E | H2max | Lmax | L2max | |

|---|---|---|---|---|---|---|---|

| APEX10 (mm) | 388.5 | 374.5 | 197.5 | Ø16 | 170 | 545.5 | 401 |

| APEX10 (inches) | 15.3 | 17.7 | 7.8 | 1/2" NPT | 6.7 | 21.5 | 15.8 |

| Connector sizes | MNPT | EN DIN | JIS |

|---|---|---|---|

| APEX10 | 0.5" | 10mm | 10mm |

| A | A1 | B | E | H2max | Lmax | L2max | |

|---|---|---|---|---|---|---|---|

| APEX15 (mm) | 394.5 | 380.5 | 197.5 | Ø20 | 170 | 545.5 | 401 |

| APEX15 (inches) | 15.5 | 15 | 7.8 | 3/4" NPT | 6.7 | 21.5 | 15.8 |

| Connector sizes | MNPT | EN DIN | JIS |

|---|---|---|---|

| APEX15 | 0.75" | 20mm | 20mm |

| A | A1 | B | E | H2max | Lmax | L2max | |

|---|---|---|---|---|---|---|---|

| APEX20 (mm) | 394.5 | 380.5 | 197.5 | Ø20 | 170 | 545.5 | 401 |

| APEX20 (inches) | 15.5 | 15 | 7.8 | 3/4" NPT | 6.7 | 21.5 | 15.8 |

| Connector sizes | MNPT | EN DIN | JIS |

|---|---|---|---|

| APEX20 | 0.75" | 20mm | 20mm |

| A | B | C | D | E | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| APEX28 (mm) | 481 | 297 | 2.5 | 264 | 98 | 338 | 370 | 415 | 221 | 359 | 124 | 82.5 | 714 | 63 | 528 | 152 | 121 | 27 | 12 |

| APEX28 (inch) | 18.9 | 11.7 | 0.1 | 10.4 | 3.9 | 13.3 | 14.6 | 16.3 | 8.7 | 14.1 | 4.9 | 3.2 | 28.1 | 2.5 | 20.8 | 6.0 | 4.8 | 1.1 | 0.5 |

| Connector sizes | ASME B16.5, 150# (ANSI) | EN 1092-1, PN40 (DIN) | JIS B2220, 10/16/20 kgf/cm2 |

|---|---|---|---|

| APEX28 | DN 1" | DN 25 | 25mm |

| A | B | C | D | E | F | G | H | H1 | H2max | J | K | Lmax | L1 | L2max | M | N | O | ØP | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| APEX35 (mm) | 557 | 335 | 2.5 | 330 | 100 | 406 | 442 | 490 | 255 | 373 | 126 | 95 | 734 | 66 | 528 | 140 | 140 | 30 | 12 |

| APEX35 (inch) | 21.9 | 13.2 | 0.1 | 13.0 | 3.9 | 16.0 | 17.4 | 19.3 | 10.0 | 14.7 | 5.0 | 3.7 | 28.9 | 2.6 | 20.8 | 5.5 | 5.5 | 1.2 | 0.5 |

| Connector sizes | ASME B16.5, 150# (ANSI) | EN 1092-1, PN40 (DIN) | JIS B2220, 10/16/20 kgf/cm2 |

|---|---|---|---|

| APEX35 | DN 1.5" | DN 32 | 32mm |

| Hose material | CSM, EPDM, F-NBR, NBR, NBR for food, NR |

| Housing | Cast iron, Die-cast aluminum (RAL 3011) |

| Rotor assembly | Cast iron, Die-cast aluminum |

| Cover assembly | Die-cast aluminum, EPDM, PMMA |

| Brackets and fasteners | Stainless steel 316 |

| Brackets | Cast iron, Stainless steel AISI 316L |

| Fasteners | Galvanized steel, Stainless steel AISI 316L |

| Support frame | Galvanized steel, Stainless steel AISI 316L |

| Hose clamps | Stainless steel 316 |

| Coupling bush | Alloy steel |

| Seals | EPDM, NBR |

Natural Rubber hose element for APEX hose pumps. Generally resistant to diluted acids and alcohols.

Hose pump elements

NBR hose element for APEX hose pumps. Resistant to non-mineral oils, greases, alkalis and detergents

Hose pump elements

EPDM hose element for APEX hose pumps. Excellent chemical resistance, especially to ketones, alcohols and concentrated acids

Hose pump elements

F-NBR hose element for APEX hose pumps. Suitable for a wide range of food products including dairy. Compliant to EC1935/2004 and FDACFR177.2600

Hose pump elements

Flow rates to 37 GPM (8500 L/h) and pressures up to 232 psi. Food quality hose compliant.

Pumps - hose pumps

Flow rates to 23.1 GPM (5250 L/h) and pressures up to 232 psi. Paint-free electroplated pump housing.

Pumps - hose pumps

Flow rates to 4623 GPH (17520 L/hr) and pressures up to 232 psi. Eliminate ancillary equipment.

Pumps - hose pumps

Flow rates to 108000 L/h (475 GPM) and pressures up to 232 psi. Eliminate ancillary equipment.

Pumps - hose pumps

To order a product or ask a question