Gentle and superior viscous fluid handling

-

![masosine certa 400 pump]()

Selecting the right pump lowers your process costs

Reduce energy costs, optimize operations and ensure product integrity.

-

![masosine certa pump 250]()

Reduce energy costs

Discover how to make your process more efficient

-

![masosine certa compact pump]()

Limited on space?

Certa Compact Sine pump is a solution when installation space is limited

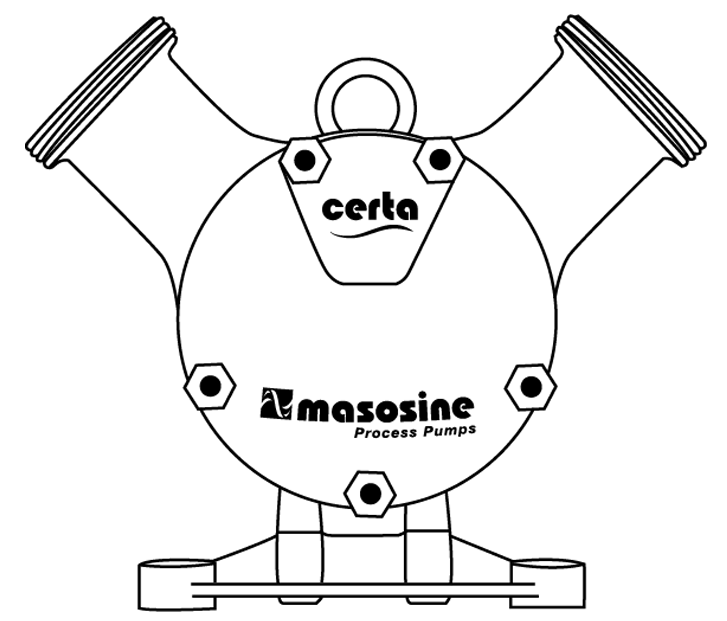

Certa process pumps

MasoSine provides energy-efficient, gentle sinusoidal pumps for food and beverage, pharmaceutical, chemical and cosmetics applications. Certa Sine® pumps from MasoSine are easy to clean and perfect for handling viscous products or fluids. With their one-shaft, one-seal design, Certa pumps significantly reduce energy consumption compared to other positive displacement pumps. Certa’s design significantly reduces the number of components, resulting in faster service times, lower maintenance costs, and minimal downtime. This boosts overall efficiency and reliability. Certa pumps have a wide range of applications including integration into beverage systems for both carbonated and non-carbonated drinks. They are also used at various stages of production by dairy and brewery companies, as well as by cosmetics manufacturers to transfer gels, creams, and pastes without causing any damage.

Certa is cleaner than any lobe or circumferential piston pump.

- EHEDG Type EL - Class I

- Now with EHEDG Type EL Aseptic Class I

- All contact parts FDA and EG1935 compliant

Contact the MasoSine team

-

Features and benefits of Certa pumps

-

- Gentle product handing preserves high quality of product – superior viscous handling

- EHEDG Type EL Class I and EHEDG Type EL Aseptic Class I

- Impressive suction capability:- 0.85 bar (Vacuum) / -12.3 psi (atm)

- Low shear and virtually no pulsation

- Outstanding energy efficient pumping principle – up to 50% less power than other pumps

- Only one shaft and one seal system – different port orientations available

- Bi-directional running

- Two-year warranty

Model

(CC = Certa Compact)Maximum Flow Maximum Pressure L/h bar Certa 100 (CC) 4,800 10 (6) Certa 200 (CC) 7,800 10 (6) Certa 250 (CC) 11,520 15 (6) Certa 300 (CC) 18,000 15 (6) Certa 400 (CC) 41,760 15 (6) Certa 500 (CC) 69,120 15 (6) Certa 600 (CC) 99,000 15 (6) Certa 800 255,360 15 Certa Plus 100 4,800 6 Certa Plus 200 7,800 6 Certa Plus 250 11,520 6 Certa Plus 300 18,000 6 Certa Plus 400 41,760 6

-

Certa Plus process pump

-

Drawing on considerable experience in sinusoidal pumping technology, Certa Plus has been developed by MasoSine to meet a broad range of applications for the pharmaceutical industry.

![certa plus process pump]()

- High suction capability to handle viscous fluids

- Low shear, zero pulsation and self-draining

- Uses up to 50 % less power than lobe and circumferential piston pump types

- Easy to clean pump design certified with EHEDG Type EL Class I, EHEDG Type EL Aseptic Class I

- Exposed fluid contact materials made of stainless steel 1.4435 material with electropolished surface

- All fluid contact materials meet the latest FDA and USP Class VI requirements

Learn more about Certa Plus

-

Certa Compact process pump

-

With a 30% reduction in footprint on the well-known Certa Sine pump from MasoSine, the Certa Compact Sine pump is a competitive format for a wide range of applications where traditionally AODD or lobe pumps would be employed. As with all Certa Sine pumps, the Certa Compact delivers energy savings as it consumes up to 50% less power than lobe or circumferential pumps with exceptional performance for all applications, including handling highly viscous products. Certa Compact has all the performance features as the rest of the Certa range, except pressure rating.

- Applications up to 6 bar / 87 PSI

- No motor coupling required

- No misalignment of motor

-

Artisan cheesemaker optimizes operations and ensures product integrity with Certa

-

Family-run cheesemaker Greenfields Dairy Products Ltd improved reliability and yield after switching to a MasoSine Certa 400 from a centrifugal pump. The Certa pump also reduced energy consumption at a time of rising energy costs. After adding the energy-efficient MasoSine Certa pump for the transfer of curds and whey across its facility in Lancashire, England, Greenfields won awards for its cheeses at an international cheese awards event.

“It was all about the technology. It’s a lot safer for us to use the MasoSine Certa because if you damage the product it can lose yield and that could affect the quality and certainly our profitability. By using the MasoSine Certa it has made our operation better.”

Featured articles

-

Case Study

![]()

Padstow Cheese quadruples output and boosts quality with help of Certa pump

Fast-growing cheese producer switches from centrifugal pump to Certa sine pump.

Case Study

-

Case Study

![]()

Italian pharmaceutical company reduces product waste when transferring gel with MasoSine Certa Plus 250 sinusoidal pump

The pharmaceutical company adopted a Certa Plus 250 and the low shear, gentle handling sinusoidal...

Case Study

-

Case Study

![]()

Independent, artisan cheesemaker chooses Certa to reduce energy costs

Investment has led to better quality of cheese, improved yield and expansion of lines.

Case Study

-

Case Study

![]()

Certa pumps eradicate yeast handling issues at German brewery

Certa Sine pumps have replaced rotary lobe pumps at the family-owned Hofmann brewery in Germany

Case Study

Contact a specialist from the MasoSine team

To order a product or ask a question call +1 800 282 8823 or