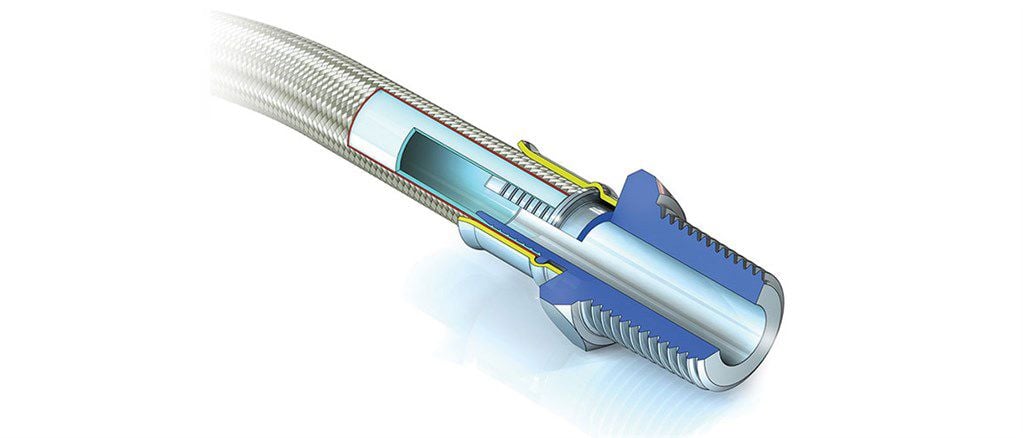

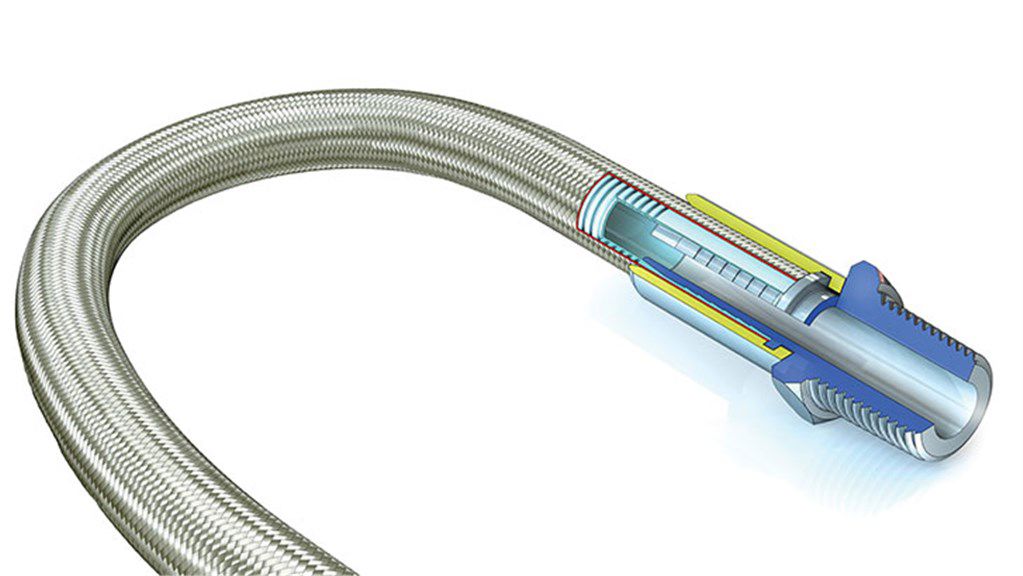

Hyperline FX hose

Smooth bore hose for all applications where improved flexibility and kink resistance are required.

Flexible hose assemblies

PTFE-lined hose for automotive and general purpose applications

Smoothbore hose comprises a straight PTFE tube liner and a stainless steel outer braid. It is the basic PTFE hose design being used successfully in many automotive and general-purpose applications. Other applications include use with high-pressure steam and gases, refrigerants, hot oils, and other hot or corrosive fluids.

| Nominal bore size | 1.5 - 50 mm |

| Nominal bore size | 0.0625 - 2 in |

| Outside diameter | 5 - 56.4 mm |

| Outside diameter | 0.197 - 2.221 in |

| Max. operating pressure | 540 bar |

| Max. operating pressure | 7800 psi |

| Certification and compliance | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 |

| Bend radius | 11 - 1,200 mm |

| Bend radius | 0.5 - 47.25 in |

| Braid | Double, Single |

| Cover | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber |

Technical Summary table lists features available within the range. See ‘Technical specifications’ tab for model specific information.

| Standard wall, single braid (SW, SB) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore size (Nominal) | Bore size (Actual) | Dash size ref (if any) | PTFE tube wall thickness | Braid outside diameter | Minimum bend radius | Maximum working pressure | Weight per unit length | *Part number | ||||||

| mm | in | mm | in | mm | in | mm | in | bar | psi | kg/mt | lbs/ft | |||

| 1/8 | 3.17 | 0.125 | - | 0.76 | 0.030 | 5.85 | 0.230 | 22 | 7/8 | 290 | 4,220 | 0.065 | 0.044 | 70-100-02-01-02 |

| 3/16 | 4.76 | 0.188 | - | 0.76 | 0.025 | 7.40 | 0.291 | 40 | 15/8 | 265 | 3,856 | 0.080 | 0.054 | 70-100-03-01-02 |

| 1/4 | 6.35 | 0.250 | - | 0.63 | 0.025 | 8.50 | 0.335 | 60 | 23/8 | 240 | 3,492 | 0.093 | 0.062 | 70-100-04-01-02 |

| 5/16 | 7.94 | 0.313 | - | 0.63 | 0.025 | 10.15 | 0.400 | 70 | 27/8 | 200 | 2,910 | 0.110 | 0.074 | 70-100-05-01-02 |

| 3/8 | 9.53 | 0.375 | - | 0.63 | 0.025 | 11.75 | 0.463 | 80 | 32/8 | 190 | 2,765 | 0.124 | 0.083 | 70-100-06-01-02 |

| 1/2 | 12.70 | 0.500 | - | 0.76 | 0.030 | 14.95 | 0.589 | 110 | 43/8 | 140 | 2,030 | 0.207 | 0.139 | 70-100-08-01-02 |

| 5/8 | 15.88 | 0.625 | - | 0.76 | 0.030 | 18.35 | 0.722 | 150 | 6 | 110 | 1,601 | 0.255 | 0.171 | 70-100-10-01-02 |

| 3/4 | 19.05 | 0.750 | - | 0.76 | 0.030 | 21.65 | 0.852 | 200 | 77/8 | 80 | 1,164 | 0.315 | 0.211 | 70-100-12-01-02 |

| 1 | 25.40 | 1.000 | - | 1.00 | 0.039 | 28.15 | 1.108 | 300 | 117/8 | 55 | 800 | 0.430 | 0.288 | 70-100-16-01-02 |

| * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 | ||||||||||||||

| Medium wall, single braid (MW, SB), also referred to as Hyperline SB | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| The Hyperline MW, SB Range meets or exceeds SAE 100R14 standard. | ||||||||||||||

Bore size (Nominal) |

Bore size (Actual) | Dash size ref (if any) | PTFE tube wall thickness | Braid outside diameter | Minimum bend radius | Max working pressure | Weight per unit length | *Part number | ||||||

| mm | in | mm | in | mm | in | mm | in | Bar | Psi | Kg/mt | Lbs/Ft | |||

| 1/16 BB | 2.0 | 0.079 | -2 | 1.00 | 0.040 | 5.00 | 0.197 | 13 | 1/2 | 450 | 6,500 | 0.045 | 0.030 | 70-300-02-01-02 |

| 1/8 BB | 3.5 | 0.138 | -3 | 1.00 | 0.040 | 6.45 | 0.254 | 20 | 3/4 | 350 | 5,076 | 0.070 | 0.047 | 70-300-03-01-02 |

| 3/16 BB | 5.0 | 0.200 | -4 | 0.76 | 0.030 | 7.65 | 0.301 | 45 | 13/4 | 290 | 4,206 | 0.078 | 0.052 | 70-400-03-01-02 |

| 1/4 BB | 6.7 | 0.264 | -5 | 0.76 | 0.030 | 9.30 | 0.366 | 60 | 23/8 | 240 | 3,480 | 0.110 | 0.074 | 70-400-04-01-02 |

| 5/16 BB | 8.4 | 0.335 | -6 | 0.76 | 0.030 | 10.72 | 0.422 | 70 | 23/4 | 220 | 3,190 | 0.136 | 0.091 | 70-400-05-01-02 |

| 3/8 BB | 10.0 | 0.394 | -7 | 0.76 | 0.030 | 12.75 | 0.500 | 80 | 3 | 190 | 2,755 | 0.166 | 0.111 | 70-400-06-01-02 |

| 1/2 BB | 13.3 | 0.536 | -10 | 0.76 | 0.030 | 16.35 | 0.644 | 130 | 5 | 150 | 2,175 | 0.210 | 0.141 | 70-400-08-01-02 |

| 5/8 BB | 16.5 | 0.654 | -12 | 0.84 | 0.033 | 19.50 | 0.768 | 163 | 61/2 | 130 | 1,885 | 0.280 | 0.188 | 70-400-10-01-02 |

| 3/4 BB | 19.8 | 0.780 | - | 1.00 | 0.040 | 22.50 | 0.860 | 180 | 7 | 110 | 1,595 | 0.327 | 0.219 | 70-400-12-01-02 |

| 1 BB | 26.4 | 1.040 | - | 1.00 | 0.040 | 30.10 | 1.190 | 230 | 9 | 80 | 1,160 | 0.524 | 0.351 | 70-400-16-01-02 |

| * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 | ||||||||||||||

| Heavy Wall, single braid (HW, SB) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore size (Nominal) | Bore size (Actual) | Dash size ref (if any) | PTFE tube wall thickness | Braid outside diameter | Minimum bend radius | Maximum working pressure | Weight per unit length | *Part number | ||||||

| mm | in | mm | in | mm | in | mm | in | bar | psi | kg/mt | lbs/ft | |||

| 1/8 | 3.17 | 0.125 | - | 1.00 | 0.039 | 6.10 | 0.240 | 20 | 7/8 | 290 | 4,220 | 0.068 | 0.046 | 70-200-02-01-02 |

| 3/16 | 4.76 | 0.188 | - | 1.00 | 0.039 | 7.65 | 0.301 | 29 | 11/8 | 270 | 3,929 | 0.087 | 0.058 | 70-200-03-01-02 |

| 1/4 | 6.35 | 0.250 | - | 1.00 | 0.039 | 9.25 | 0.364 | 30 | 12/8 | 260 | 3,783 | 0.113 | 0.076 | 70-200-04-01-02 |

| 5/16 | 7.94 | 0.313 | - | 1.00 | 0.039 | 10.90 | 0.429 | 40 | 15/8 | 230 | 3,347 | 0.135 | 0.091 | 70-200-05-01-02 |

| 3/8 | 9.53 | 0.375 | - | 1.00 | 0.039 | 12.50 | 0.492 | 55 | 22/8 | 200 | 2,910 | 0.153 | 0.103 | 70-200-06-01-02 |

| 1/2 | 12.70 | 0.500 | - | 1.00 | 0.039 | 15.60 | 0.614 | 85 | 33/8 | 160 | 2,328 | 0.240 | 0.161 | 70-200-08-01-02 |

| 5/8 | 15.88 | 0.625 | - | 1.30 | 0.051 | 19.10 | 0.752 | 110 | 43/8 | 130 | 1,892 | 0.292 | 0.196 | 70-200-10-01-02 |

| 3/4 | 19.05 | 0.750 | - | 1.30 | 0.051 | 22.05 | 0.868 | 145 | 56/8 | 92 | 1,339 | 0.344 | 0.231 | 70-200-12-01-02 |

| 1 | 25.40 | 1.000 | - | 1.50 | 0.059 | 28.80 | 1.134 | 260 | 102/8 | 69 | 1,004 | 0.470 | 0.315 | 70-200-16-01-02 |

| * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 | ||||||||||||||

| Standard wall, double braid (SW, DB) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore size (Nominal) | Bore size (Actual) | Dash size ref (if any) | PTFE tube wall thickness | Braid outside diameter | Minimum bend radius | Maximum working pressure | Weight per unit length | *Part number | ||||||

| mm | in | mm | in | mm | in | mm | in | bar | psi | kg/mt | lbs/ft | |||

| 1/8 | 3.17 | 0.125 | - | 0.76 | 0.030 | 6.85 | 0.270 | 20 | 7/8 | 360 | 5,238 | 0.100 | 0.067 | 70-100-02-02-02 |

| 3/16 | 4.76 | 0.188 | - | 0.76 | 0.025 | 8.70 | 0.343 | 30 | 11/4 | 330 | 4,802 | 0.135 | 0.091 | 70-100-03-02-02 |

| 1/4 | 6.35 | 0.250 | - | 0.63 | 0.025 | 10.05 | 0.396 | 40 | 15/8 | 290 | 4,220 | 0.160 | 0.107 | 70-100-04-02-02 |

| 5/16 | 7.94 | 0.313 | - | 0.63 | 0.025 | 11.55 | 0.455 | 50 | 2 | 250 | 3,638 | 0.190 | 0.127 | 70-100-05-02-02 |

| 3/8 | 9.53 | 0.375 | - | 0.63 | 0.025 | 13.35 | 0.526 | 60 | 23/8 | 230 | 3,347 | 0.214 | 0.143 | 70-100-06-02-02 |

| 1/2 | 12.70 | 0.500 | - | 0.76 | 0.030 | 16.40 | 0.646 | 90 | 35/8 | 180 | 2,629 | 0.341 | 0.229 | 70-100-08-02-02 |

| 5/8 | 15.88 | 0.625 | - | 0.76 | 0.030 | 19.95 | 0.785 | 130 | 51/8 | 135 | 1,964 | 0.416 | 0.279 | 70-100-10-02-02 |

| 3/4 | 19.05 | 0.750 | - | 0.76 | 0.030 | 23.10 | 0.910 | 170 | 63/4 | 100 | 1,455 | 0.503 | 0.337 | 70-100-12-02-02 |

| 1 | 25.40 | 1.000 | - | 1.00 | 0.039 | 29.60 | 1.165 | 270 | 103/4 | 70 | 1019 | 0.430 | 0.700 | 70-100-16-02-02 |

| * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 | ||||||||||||||

| Heavy Wall, double braid (HW, DB) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bore size (Nominal) | Bore size (Actual) | Dash size ref (if any) | PTFE tube wall thickness | Braid outside diameter | Minimum bend radius | Maximum working pressure | Weight per unit length | *Part number | ||||||

| mm | in | mm | in | mm | in | mm | in | bar | psi | kg/mt | lbs/ft | |||

| 1/8 | 3.17 | 0.125 | - | 1.00 | 0.039 | 7.05 | 0.278 | 18 | 3/4 | 350 | 5,093 | 0.108 | 0.072 | 70-200-02-02-02 |

| 3/16 | 4.76 | 0.188 | - | 1.00 | 0.039 | 8.90 | 0.350 | 25 | 1 | 320 | 4,656 | 0.140 | 0.094 | 70-200-03-02-02 |

| 1/4 | 6.35 | 0.250 | - | 1.00 | 0.039 | 10.75 | 0.423 | 26 | 11/8 | 310 | 4,511 | 0.183 | 0.123 | 70-200-04-02-02 |

| 5/16 | 7.94 | 0.313 | - | 1.00 | 0.039 | 12.35 | 0.486 | 35 | 11/2 | 275 | 4,001 | 0.210 | 0.141 | 70-200-05-02-02 |

| 3/8 | 9.53 | 0.375 | - | 1.00 | 0.039 | 14.10 | 0.555 | 50 | 2 | 240 | 3,492 | 0.243 | 0.163 | 70-200-06-02-02 |

| 13/32 | 10.32 | 0.406 | - | 1.00 | 0.039 | 15.05 | 0.593 | 60 | 23/8 | 230 | 3,347 | 0.258 | 0.173 | 70-500-13-02-02 |

| 1/2 | 12.70 | 0.500 | - | 1.00 | 0.039 | 16.90 | 0.665 | 75 | 3 | 200 | 2,900 | 0.374 | 0.251 | 70-200-08-02-02 |

| 5/8 | 15.88 | 0.625 | - | 1.30 | 0.051 | 20.75 | 0.817 | 100 | 4 | 155 | 2,255 | 0.452 | 0.303 | 70-200-10-02-02 |

| 3/4 | 19.05 | 0.750 | - | 1.30 | 0.051 | 23.80 | 0.937 | 135 | 53/8 | 110 | 1,601 | 0.532 | 0.356 | 70-200-12-02-02 |

| 1 | 25.40 | 1.000 | - | 1.50 | 0.059 | 30.70 | 1.209 | 250 | 97/8 | 84 | 1,222 | 0.730 | 0.489 | 70-200-16-02-02 |

| * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 * For Anti-Static Grade, add 10 to the 3-digit part number e.g. 70-100- becomes 70-110 | ||||||||||||||

| Standard wall, single braid hoses | Medium wall, single braid hoses | Heavy wall, single braid hoses | Standard wall, double braid hoses | Medium wall, double braid hoses | Heavy wall, double braid hoses | |

| Nominal bore size | 0.1875 - 1 in (5 - 25 mm) | 0.0625 - 1 in (1.5 - 25 mm) | 0.125 - 1 in (3 - 25 mm) | 0.125 - 1 in (3 - 25 mm) | 0.0625 - 1 in (1.5 - 25 mm) | 0.125 - 2 in (3 - 50 mm) |

| Actual bore size | 0.188 - 1 in (4.76 - 25.4 mm) | 0.079 - 1.04 in (2 - 26.4 mm) | 0.125 - 1 in (3.17 - 25.4 mm) | 0.125 - 1 in (3.17 - 25.4 mm) | 0.079 - 1.04 in (2 - 26.4 mm) | 0.125 - 2 in (3.17 - 50.8 mm) |

| Outside diameter | 0.291 - 1.108 in (7.4 - 28.15 mm) | 0.197 - 1.19 in (5 - 30.1 mm) | 0.24 - 1.134 in (6.1 - 28.8 mm) | 0.27 - 1.165 in (6.85 - 29.6 mm) | 0.236 - 1.249 in (6 - 31.7 mm) | 0.278 - 2.221 in (7.05 - 56.4 mm) |

| Max. operating pressure | 2910 psi (265 bar) | 6500 psi (450 bar) | 4220 psi (290 bar) | 5238 psi (360 bar) | 7800 psi (540 bar) | 5093 psi (350 bar) |

| Burst pressure | 2400 - 8,730 psi (165 - 795 bar) | 3480 - 19,500 psi (240 - 1,350 bar) | 3012 - 12,660 psi (207 - 870 bar) | 3057 - 15,714 psi (210 - 1,080 bar) | 4200 - 23,400 psi (300 - 1,620 bar) | 1746 - 15,279 psi (120 - 1,050 bar) |

| Certification and compliance | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1401, SAE J1737, TS 16949:2016 |

| Operating temperature | -100 °F to 500 °F (-73 °C to 260 °C) | -100 °F to 500 °F (-73 °C to 260 °C) | -100 °F to 500 °F (-73 °C to 260 °C) | -100 °F to 500 °F (-73 °C to 260 °C) | -100 °F to 500 °F (-73 °C to 260 °C) | -100 °F to 500 °F (-73 °C to 260 °C) |

| Bend radius | 1.625 - 11.875 in (40 - 300 mm) | 0.5 - 9 in (13 - 230 mm) | 0.875 - 10.25 in (20 - 260 mm) | 0.875 - 10.75 in (20 - 270 mm) | 0.5 - 8.25 in (11 - 210 mm) | 0.75 - 47.25 in (18 - 1,200 mm) |

| Weight per unit length | 0.054 - 0.288 lb/ft (0.08 - 0.43 kg/m) | 0.03 - 0.351 lb/ft (0.045 - 0.524 kg/m) | 0.046 - 0.315 lb/ft (0.068 - 0.47 kg/m) | 0.067 - 0.469 lb/ft (0.1 - 0.7 kg/m) | 0.05 - 0.55 lb/ft (0.075 - 0.83 kg/m) | 0.072 - 1.079 lb/ft (0.108 - 1.61 kg/m) |

| Braid | Single | Single | Single | Double | Double | Double |

| Cover | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber | EPDM rubber, Flexible PVC, Hytrel, Nylon II, Sarlink, Silicone rubber |

| End fitting | Hydraulic tail end fittings, PTFE tail end fittings | Hydraulic tail end fittings, PTFE tail end fittings | Hydraulic tail end fittings, PTFE tail end fittings | Hydraulic tail end fittings, PTFE tail end fittings | Hydraulic tail end fittings, PTFE tail end fittings | Hydraulic tail end fittings, PTFE tail end fittings |

| Vacuum resistance | Vacuum resistant to -0.9bar | Vacuum resistant to -0.9bar |

| Liner tube | Antistatic PTFE, HPG PTFE, Natural PTFE |

| Wire braid | Aramid fiber, Stainless steel |

| Hose | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Tube only -TO | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Stainless Steel - SS | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Rubber Covered - RC | ✔ | ✔ | ✔ | ✔ | |||||

| Polypropylene Braid - PB | ✔ | ✔ | |||||||

| Platinum Cured - SI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Braids | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Plastic Rubber option | ✔ | ✔ | ✔ | ||||||

| Aramid | ✔ | ||||||||

| Kynar Braid | ✔ | ||||||||

| Hastelloy Braid | ✔ | ||||||||

| Blue EPDM | ✔ | ✔ | ✔ | ||||||

| Black EPDM | ✔ | ✔ | ✔ | ||||||

| External protections | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Safeguard Protection Sleeve - SG | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Scuff Ring - SR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Protection Coil - PC | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Double Rubber Cover End Protection - RC300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Double Rubber Cover End Protection - DBK300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

|---|---|---|---|---|---|---|---|---|---|

| Swivel Flange Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Swivel Flange Fittings - Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Male Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Male Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Female Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Female Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Sanitary Triclamp Fittings PTFE Lined and Flared | ✔ | ✔ | ✔ | ||||||

| Sanitary Triclamp Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary & Mini Sanitary | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary Triclamp Fittings - 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| DIN 11851 / SMS Fittings - PTFE Lined | ✔ | ✔ | ✔ | ||||||

| DIN 11851 Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| RJT Female Fittings - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| BSP & NPT Threaded Fittings - NPT & BSPT Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| BSP & NPT Threaded Fitting - BSP 60° Cone seat female fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| JIC Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| PTFE Dip Pipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 3-A Sanitary Fittings | ✔ | ✔ | ✔ | ✔ | |||||

| 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Grooved Standpipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| IDF Female / Male - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| ENCAP Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| PTFE Tail or Hydraulic Fittings | ✔ | ✔ | ✔ | ||||||

| PTFE Tail Fittings | ✔ | ✔ | ✔ | ✔ |

Specify all requirements in order shown below:

| Example | ||

|---|---|---|

| Written description | 4 off x 1” bore Bioflex Ultra, AS, SS, RC, DRC-300 hose x 3.00 metres long. Both ends non-lined ANSI 150# S/S Flanges |

|

| Part numbers | 4 off Part No. 16-BFXU/AS-RC-00-3.00m-12-12, with DRC 300 at both ends. | |

Special requirements:

Specify full written description on enquiry or purchase order:

| PTFE liner | Braids | Rubber covers |

|---|---|---|

| Natural (GP) | 316 stainless steel (SS) | Platinum cured silicone |

| Antistatic (AS) | Polypropylene (PB) | Blue EPDM rubber cover (RC) |

| Black EPDM rubber cover (BK) |

External protections available – see braid, covers and end fittings page.

LISTED MINIMUM LENGTHS DO NOT INCLUDE FITTINGS.

Hose length + end fittings = Total hose assembly length (sealing face to sealing face)

Lengths made to customer requirement. Tolerance +2 %/-0 %. Closer tolerances available to special order.

| Nominal Size of Hose | Minimum Hose Length Between Fittings | Maximum Hose Assembly Length Longer lengths may be available by special order |

||

|---|---|---|---|---|

| Used Straight | Flexed Through 90° | |||

| All Grades | TO, KYB Grades | SS, PB RC Grades | ||

| inches (mm) | inches (mm) | inches (mm) | inches (mm) | Metres (ft) |

| 3/8 (10) | 3 (75) | 3.00 (75) | 3.00 (75) | 100 (30) |

| 1/2 (15) | 3 (75) | 3.00 (75) | 3.00 (75) | 100 (30) |

| 5/8 (16) | 3 (75) | 4.00 (100) | 3.00 (75) | 100 (30) |

| 3/4 (20) | 3 (75) | 4.72 (120) | 4.00 (100) | 100 (30) |

| 7/8 (22) | 3 (75) | 5.71 (145) | 4.00 (100) | 100 (30) |

| 1 (25) | 3 (75) | 6.89 (175) | 4.33 (110) | 100 (30) |

| 11/4 (32) | 4 (100) | 8.66 (220) | 6.30 (160) | 100 (30) |

| 13/8 (35) | 4 (100) | 10.04 (255) | 7.48 (190) | 100 (30) |

| 11/2 (40) | 4 (100) | 11.22 (285) | 8.66 (220) | 100 (30) |

| 17/8 (48) | 4 (100) | 17.32 (440) | 11.81 (300) | 100 (30) |

| 2 (50) | 4 (100) | 18.70 (475) | 12.40 (315) | 100 (30) |

| 21/2 (65) | 4 (100) | 27.95 (710) | 18.70 (475) | 60 (18) |

| 3 (80) | 4 (100) | 32.48 (825) | 21.65 (550) | 50 (15) |

Large range of ‘standard’ end fittings available.

Special order—non-standard grades of SS or materials such as Hastelloy or Monel.

| Specification Equivalents | |||

|---|---|---|---|

| Grade | BS British Standard |

AISI American Standard or C = Casting Grade |

EN European Norm |

| 316L SS | BS 316 S11 | AISI 316 L | EN1.4404 |

| 316C SS | BS 316 C16 | CF8M | EN 1.4408 |

| 304 SS | BS 304 S15 | AISI 304 | EN 1.4301 |

Smooth bore hose for all applications where improved flexibility and kink resistance are required.

Flexible hose assemblies

Convoluted bore hose for all applications where a smooth bore and/or high pressures are not required.

Flexible hose assemblies

To order a product or ask a question