Watson-Marlow 114DV pumphead meets the performance criteria of Anthogyr’s dental implant device

Compact peristaltic pump easily integrates into device for irrigation management

Case Study

The 100 series combines performance, practicality and design. With its iconic flip-top design it is an industry standard OEM product in medical device, biotechnology and diagnostic applications, and very popular in many other applications too.

Delivering accurate, repeatable and low-pulse flow rates in a compact size, the 100 series has a spring-loaded track to provide pressure control that can be set for standard and higher pressures. Pumps are highly engineered to deliver long tube life. Available in a range of colours and options including open/close sensor, rotation sensor and customised occlusion.

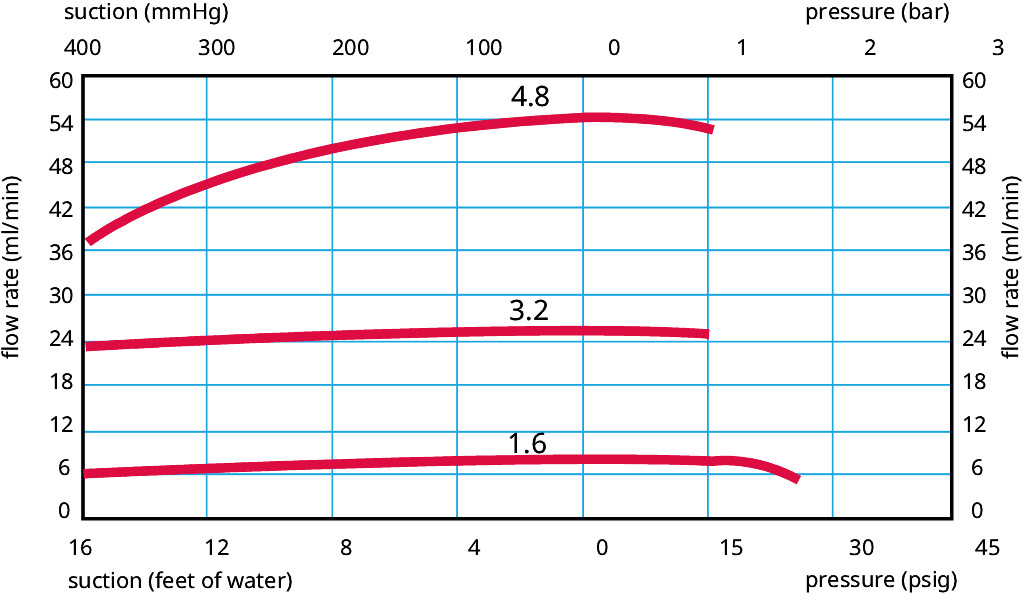

102R low-flow pumpheads accept, without adjustment, all Watson-Marlow tubing from 0.5 mm to 4.8 mm internal diameter with 1.6 mm wall thickness. The pumphead has a spring-loaded, two roller rotor and is suitable for continuous use up to 65 rpm providing flow rates up to 106 ml/min.

Capable of pumping in either direction, 102R set to clockwise rotation will give a longer tube life. Anticlockwise rotation is suitable for pumping against greater pressures. The pumphead is available with a choice of track materials and rotor springs and is suitable for either a 6 mm or 8 mm drive shaft if mounted on users' drive.

All 102R pumpheads have a choice of mounting points and a shatterproof clear polycarbonate guard which is hinged to allow easy access for tube changing.

Snap-in connectors are also available, in place of the sprung tube clamps.

| Max. flow rate continuous | 340 ml/min |

| Pump type | Cased, Panel mount |

| Weight | 0.1 kg |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| 114 pumphead for continuous 1.6mm wall tubing — Flow rates (ml/min) | |||||

|---|---|---|---|---|---|

| Speed (rpm) | |||||

| Tube bore (mm) | (ml/rev) | 100 | 400 | 600 (intermittent) | |

| 0.5 | 0.02 | 2.2 | 9.1 | 13.5 | |

| 0.8 | 0.04 | 4.3 | 17 | 26 | |

| 1.6 | 0.14 | 14 | 56 | 84 | |

| 2.4 | 0.29 | 29 | 115 | 175 | |

| 3.2 | 0.47 | 47.5 | 190 | 285 | |

| 4.0 | 0.67 | 67 | 270 | 405 | |

| 4.8 | 0.85 | 85 | 340 | 510 | |

| Custom options |

|---|

| Pumphead options |

| No visible rotation - covered holes |

| Logic off switch and rotation sensor |

| Custom colours |

| Models for thin wall tubing |

| Custom occlusion settings |

| Silent version available |

| 102R low flow pumphead for continuous 1.6mm wall tubing — Flow rates (ml/min) | |||

|---|---|---|---|

| Speed (rpm) | |||

| Tube bore (mm) | (ml/rev) | 65 | 130 |

| 0.5 | 0.02 | 1.38 | 2.76 |

| 0.8 | 0.05 | 3.22 | 6.44 |

| 1.6 | 0.22 | 14.0 | 28.0 |

| 3.2 | 0.81 | 52.0 | 104 |

| 4.8 | 1.66 | 106 | 212 |

| 1.6mm wall tubing | |||||

|---|---|---|---|---|---|

| Bore (mm) | 0.5 | 0.8 | 1.6 | 3.2 | 4.8 |

| Maximum continous speed (rpm) | 65 | 65 | 65 | 65 | 65 |

| Maximum intermittent speed (rpm) | 130 | 130 | 130 | 130 | 130 |

| With silicone tubing (standard springs, clockwise rotation) | |||||

| Required torque up to 0.5bar (kg cm) | 1.1 | 1.1 | 1.2 | 1.5 | 1.8 |

| Required torque up to 1bar (kg cm) | 1.2 | 1.2 | 1.25 | 1.8 | 2.1 |

| Maximum pressure (bar) | 3.0 | 3.0 | 3.0 | 1.0 | 1.0 |

| With Marprene tubing (hard springs, clockwise rotation) | |||||

| Required torque up to 0.5bar (kg cm) | 3.5 | 3.5 | 3.6 | 4.2 | 4.6 |

| Maximum pressure (bar) | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

Conditions:

Conversion Factors:

| 114DV pumphead | 102R pumphead | |

| Number of channels | 1 | 1 |

| Number of rollers | 4 | 2 |

| Max. flow rate continuous | 340 ml/min | 106 ml/min |

| Max. flow rate intermittent | 510 ml/min | 212 ml/min |

| Max. continuous operating speed | 400 rpm | 65 rpm |

| Operating torque | 0.25 N m | |

| Operating temperature | -10 °C to 45 °C (14 °F to 113 °F) | |

| Pump type | Cased, Panel mount | Cased, Panel mount |

| Weight | 0.1 kg (0.22 lbs) | |

| Compatible tubing bore size | 0.5, 0.8, 1.6, 2.4, 3.2, 4, 4.8 mm | 0.5, 0.8, 1.6, 3.2, 4.8 mm |

| Compatible tubing wall thickness | 1.6, 2.4 mm | 1.6 mm |

| Bearings | Stainless steel |

| Pumphead body assembly | Acetal copolymer (Kematal), Grilamid PA12, Polyacrylamide—IXEF (PARA), Polycarbonate (PC), PVDF |

| Pumphead guard | Polycarbonate (PC) |

| Pumphead track | Acetal copolymer (Kematal), Polyacrylamide—IXEF (PARA), PVDF |

| Pumphead roller assembly | MoS2 filled Nylon 6 (Nylatron), PTFE filled PBT |

| Pumphead rotor assembly | FPM rubber, IXEF (Polyarylamide), Polyacrylamide—IXEF (PARA), PTFE filled PBT, Stainless steel |

Information listed covers the complete range. For detailed specifications of individual models/components refer to user manual or contact WMFTS representative.

| Description | Part code |

|---|---|

| 114DV standard pumphead | 013.5000.00A |

| 114DVP +pressure pumphead | 013.5000.P0A |

| Bore/wall | Pumpsil | Marprene | Bioprene | STA-PURE PFL | PVC* |

|---|---|---|---|---|---|

| 0.5/1.6mm | 913.A005.016 | 902.0005.016 | 933.0005.016 | ||

| 0.8/1.6mm | 913.A008.016 | 902.0008.016 | 933.0008.016 | ||

| 1.6/1.6mm | 913.A016.016 | 902.0016.016 | 933.0016.016 | 966.0016.016 | E3603.016.16 |

| 2.4/1.6mm | 913.A024.016 | 902.0024.016 | 933.0024.016 | ||

| 3.2/1.6mm | 913.A032.016 | 902.0032.016 | 933.0032.016 | 966.0032.016 | E3603.032.16 |

| 4.0/1.6mm | 933.0040.016 | E3603.040.16 | |||

| 4.8/1.6mm | 913.A048.016 | 902.0048.016 | 933.0048.016 | 966.0048.016 | E3603.048.16 |

| Bore/wall | STA-PURE PCS | ||||

| 0.5/1.6mm | |||||

| 0.8/1.6mm | |||||

| 1.6/1.6mm | 961.0016.016 | ||||

| 2.4/1.6mm | |||||

| 3.2/1.6mm | 961.0032.016 | ||||

| 4.0/1.6mm | |||||

| 4.8/1.6mm | 961.0048.016 |

*recommended for 114DVP +pressure pumphead only

| For 6mm drive shaft | Suitable for | Part code |

|---|---|---|

| Kematal track with standard springs | Platinum cured Silicone | 013.2001.000 |

| Kematal track with hard springs | Marprene/PVC | 013.2011.000 |

| PVDF track with standard springs | Platinum cured Silicone | 013.3001.000 |

| PVDF track with hard springs | Marprene/PVC | 013.3011.000 |

| For 8mm drive shaft | Suitable for | Part code |

| Kematal track with standard springs | Platinum cured Silicone | 013.2101.000 |

| Kematal track with hard springs | Marprene/PVC | 013.2111.000 |

| PVDF track with standard springs | Platinum cured Silicone | 013.3101.000 |

| PVDF track with hard springs | Marprene/PVC | 013.3111.000 |

Compact peristaltic pump easily integrates into device for irrigation management

Case Study

Iconic flip-top pumps for flows up to 500 ml/min. Accurate flow performance to medium pressures.

Pumps - panel mount pumps

High quality silicone and chemical resistant TPE tubing. Over 50 bore/wall sizes and element lengths available.

Tubing - peristaltic

Thermoplastic tubing with long peristaltic life and low permeability. 5 ºC to 80 ºC (23 ºF to 176 ºF).

Tubing - peristaltic

Platinum-cured silicone tubing with ultra smooth bore and excellent flow stability. -20 ºC to 80 ºC (-4 ºF to 176 ºF).

Tubing - peristaltic

Iconic flip-top pumps for flows up to 500 ml/min. Accurate flow performance to medium pressures.

Pumps - panel mount pumps

Iconic flip-top pumps for medium flows to 2,000 ml/min. Extendable up to 6 channels.

Pumpheads

High accuracy microcassettes for manifold tubing for flow rates up to 53 ml/min.

Pumpheads

One to eight channel pumps for medium flows to 200 ml/min. Compact design and Luer connectors for 'fit and forget' applications.

Pumpheads

To order a product or ask a question