Certa plus pump

Low shear, zero pulsation and self-draining pump certified with EHEDG Type EL Class I and EHEDG Type EL Aseptic Class I.

Pumps - sine pumps

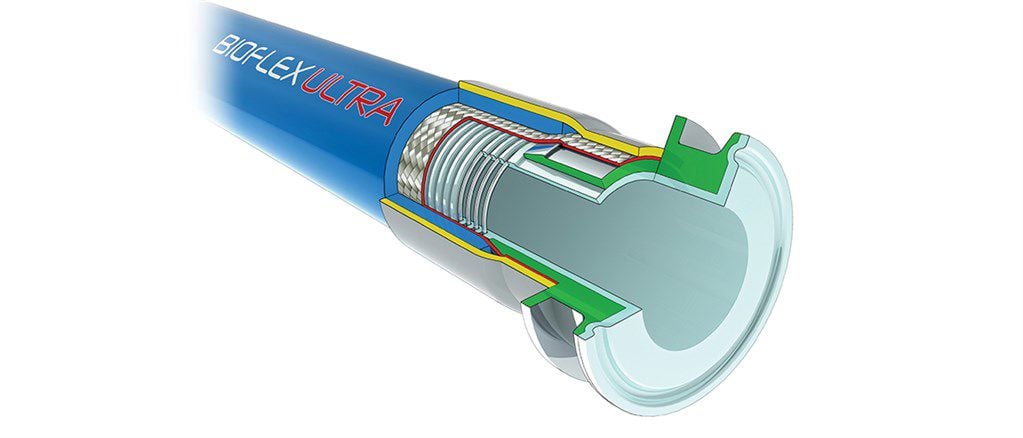

PTFE-lined hose for biotechnology and pharmaceutical fluid transfers

Chemically inert and easy to clean, Bioflex Ultra is a corrosion resistant hose for the pharmaceutical, food and beverage and chemical industries. This flexible hose provides reliability, performance and long service life.

| Nominal bore size | 9.5 - 80 mm |

| Nominal bore size | 0.375 - 3 in |

| Outside diameter | 12 - 94.8 mm |

| Outside diameter | 0.47 - 3.732 in |

| Max. operating pressure | 80 bar |

| Max. operating pressure | 1160 psi |

| Certification and compliance | 3.1 Traceability, 3-A 62-02, Anti-static to BS5173 section 103.13 part 6.2 and 6.3, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), Fireproof to BS5173 section 103.13 part 6.2 and 6.3, ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class |

| Bend radius | 19 - 350 mm |

| Bend radius | 0.75 - 13.75 in |

| Braid type | None |

| Cover | EPDM, None, Silicone rubber |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| Nominal hose bore size | Actual bore size | Bioflex Ultra grade (cover) | Helical wire | Maximum working pressure of hose | Burst pressure | Minimum bend radius | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | bar | psi | bar | psi | in | mm | ||

| 3⁄8 | 9.5 | 0.382 | 9.7 | RC/BK/SI | - | 80 | 1160 | 500 | 7200 | 3⁄4 | 19 |

| 1⁄2 | 15 | 0.516 | 13.1 | RC/BK/SI | ✓ | 70 | 1015 | 400 | 5800 | 11⁄2 | 38 |

| 5⁄8 | 16 | 0.638 | 16.2 | RC/BK/SI | ✓ | 65 | 940 | 380 | 5500 | 13⁄4 | 45 |

| 3⁄4 | 20 | 0.760 | 19.3 | RC/BK/SI | ✓ | 60 | 870 | 300 | 4350 | 2 | 50 |

| *7⁄8 | 22 | 0.870 | 22.1 | RC/BK/SI | ✓ | 55 | 800 | 220 | 3200 | 21⁄8 | 55 |

| 1 | 25 | 1.012 | 25.7 | RC/BK/SI | ✓ | 50 | 720 | 200 | 2900 | 23⁄4 | 70 |

| 11⁄4 | 32 | 1.268 | 32.2 | RC/BK/SI | ✓ | 45 | 650 | 180 | 2600 | 4 | 100 |

| *13⁄8 | 35 | 1.370 | 34.8 | RC/BK/SI | ✓ | 40 | 580 | 160 | 2320 | 4 | 100 |

| 11⁄2 | 40 | 1.516 | 38.5 | RC/BK/SI | ✓ | 40 | 580 | 160 | 2320 | 51⁄2 | 140 |

| *17⁄8 | 48 | 1.866 | 47.4 | RC/BK/SI | ✓ | 35 | 500 | 140 | 2000 | 65⁄8 | 170 |

| 2 | 50 | 2.012 | 51.1 | RC/BK/SI | ✓ | 30 | 430 | 120 | 1750 | 8 | 200 |

| 21⁄2 | 65 | 2.508 | 63.7 | RC/BK/SI | ✓ | 20 | 290 | 80 | 1160 | 117⁄8 | 300 |

| 3 | 80 | 3.024 | 76.8 | RC/BK/SI | ✓ | 15 | 218 | 60 | 870 | 133⁄4 | 350 |

| RC = Blue EPDM rubber cover, BK = Black EPDM rubber cover, SI = Silicone rubber cover | |||||||||||

*The 7⁄8", 13⁄8" and 17⁄8" hose sizes are only suitable for use with PTFE lined sanitary clamp (or triclover) end fittings and PTFE lined I-Line end fittings.

** The maximum working pressure (MWP) of a hose assembly is limited to the lowest of the MWP’s of either of the two end fittings, or of the hose itself as listed above. The MWP of the hose reduces as the operating temperature increases, consult Aflex Hose for guidance.

| Nominal hose bore size | Actual bore size | Bioflex Ultra grade (braid) | Helical wire | Maximum working pressure of hose | Burst pressure | Minimum bend radius | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | bar | psi | bar | psi | in | mm | ||

| ½ | 15 | 0.516 | 13.1 | PB | ✓ | 35 | 500 | 140 | 2000 | 1½ | 38 |

| ⅝ | 16 | 0.638 | 16.2 | PB | ✓ | 33 | 480 | 130 | 1900 | 1¾ | 45 |

| ¾ | 20 | 0.760 | 19.3 | PB | ✓ | 30 | 440 | 120 | 1750 | 2 | 50 |

| *⅞ | 22 | 0.870 | 22.1 | PB | ✓ | 27.5 | 400 | 110 | 1600 | 2⅛ | 55 |

| 1 | 25 | 1.012 | 25.7 | PB | ✓ | 25 | 360 | 100 | 1450 | 2¾ | 70 |

| 1¼ | 32 | 1.268 | 32.2 | PB | ✓ | 23 | 330 | 90 | 1300 | 4 | 100 |

| *1⅜ | 35 | 1.370 | 34.8 | PB | ✓ | 20 | 290 | 80 | 1160 | 4 | 100 |

| 1½ | 40 | 1.516 | 38.5 | PB | ✓ | 20 | 290 | 80 | 1160 | 5½ | 140 |

| *1⅞ | 48 | 1.866 | 47.4 | PB | ✓ | 18 | 250 | 72 | 1040 | 6⅝ | 170 |

| 2 | 50 | 2.012 | 51.1 | PB | ✓ | 15 | 215 | 60 | 870 | 8 | 200 |

| 2½ | 65 | 2.508 | 63.7 | PB | ✓ | 12 | 174 | 48 | 696 | 11⅞ | 300 |

| 3 | 80 | 3.024 | 76.8 | PB | ✓ | 10 | 145 | 40 | 580 | 13¾ | 350 |

| PB = Polypropylene braid | |||||||||||

*The ⅞", 1⅜" and 1⅞" hose sizes are only suitable for use with PTFE lined sanitary clamp (or triclover) end fittings and PTFE lined I-Line end fittings.

** The maximum working pressure (MWP) of a hose assembly is limited to the lowest of the MWP’s of either of the two end fittings, or of the hose itself as listed above. The MWP of the hose reduces as the operating temperature increases, consult Aflex Hose for guidance.

| Nominal hose bore size | Actual bore size | Bioflex Ultra grade (cover) | Helical wire | Maximum working pressure of hose | Burst pressure | Minimum bend radius | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | bar | psi | bar | psi | in | mm | ||

| 3⁄8 | 9.5 | 0.382 | 9.7 | RC/BK/SI | - | 80 | 1160 | 500 | 7200 | 3⁄4 | 19 |

| 1⁄2 | 15 | 0.516 | 13.1 | RC/BK/SI | ✓ | 70 | 1015 | 400 | 5800 | 11⁄2 | 38 |

| 5⁄8 | 16 | 0.638 | 16.2 | RC/BK/SI | ✓ | 65 | 940 | 380 | 5500 | 13⁄4 | 45 |

| 3⁄4 | 20 | 0.760 | 19.3 | RC/BK/SI | ✓ | 60 | 870 | 300 | 4350 | 2 | 50 |

| *7⁄8 | 22 | 0.870 | 22.1 | RC/BK/SI | ✓ | 55 | 800 | 220 | 3200 | 21⁄8 | 55 |

| 1 | 25 | 1.012 | 25.7 | RC/BK/SI | ✓ | 50 | 720 | 200 | 2900 | 23⁄4 | 70 |

| 11⁄4 | 32 | 1.268 | 32.2 | RC/BK/SI | ✓ | 45 | 650 | 180 | 2600 | 4 | 100 |

| *13⁄8 | 35 | 1.370 | 34.8 | RC/BK/SI | ✓ | 40 | 580 | 160 | 2320 | 4 | 100 |

| 11⁄2 | 40 | 1.516 | 38.5 | RC/BK/SI | ✓ | 40 | 580 | 160 | 2320 | 51⁄2 | 140 |

| *17⁄8 | 48 | 1.866 | 47.4 | RC/BK/SI | ✓ | 35 | 500 | 140 | 2000 | 65⁄8 | 170 |

| 2 | 50 | 2.012 | 51.1 | RC/BK/SI | ✓ | 30 | 430 | 120 | 1750 | 8 | 200 |

| 21⁄2 | 65 | 2.508 | 63.7 | RC/BK/SI | ✓ | 20 | 290 | 80 | 1160 | 117⁄8 | 300 |

| 3 | 80 | 3.024 | 76.8 | RC/BK/SI | ✓ | 15 | 218 | 60 | 870 | 133⁄4 | 350 |

| RC = Blue EPDM rubber cover, BK = Black EPDM rubber cover, SI = Silicone rubber cover | |||||||||||

*The 7⁄8", 13⁄8" and 17⁄8" hose sizes are only suitable for use with PTFE lined sanitary clamp (or triclover) end fittings and PTFE lined I-Line end fittings.

** The maximum working pressure (MWP) of a hose assembly is limited to the lowest of the MWP’s of either of the two end fittings, or of the hose itself as listed above. The MWP of the hose reduces as the operating temperature increases, consult Aflex Hose for guidance.

| Nominal hose bore size | Actual bore size | Bioflex Ultra grade (braid) | Helical wire | Maximum working pressure of hose | Burst pressure | Minimum bend radius | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | bar | psi | bar | psi | in | mm | ||

| 3⁄8 | 9.5 | 0.382 | 9.7 | SS | - | 80 | 1160 | 500 | 7200 | 3⁄4 | 19 |

| 1⁄2 | 15 | 0.516 | 13.1 | SS | ✓ | 70 | 1015 | 400 | 5800 | 11⁄2 | 38 |

| 5⁄8 | 16 | 0.638 | 16.2 | SS | ✓ | 65 | 940 | 380 | 5500 | 13⁄4 | 45 |

| 3⁄4 | 20 | 0.760 | 19.3 | SS | ✓ | 60 | 870 | 300 | 4350 | 2 | 50 |

| *7⁄8 | 22 | 0.870 | 22.1 | SS | ✓ | 55 | 800 | 220 | 3200 | 21⁄8 | 55 |

| 1 | 25 | 1.012 | 25.7 | SS | ✓ | 50 | 720 | 200 | 2900 | 23⁄4 | 70 |

| 11⁄4 | 32 | 1.268 | 32.2 | SS | ✓ | 45 | 650 | 180 | 2600 | 4 | 100 |

| *13⁄8 | 35 | 1.370 | 34.8 | SS | ✓ | 40 | 580 | 160 | 2320 | 4 | 100 |

| 11⁄2 | 40 | 1.516 | 38.5 | SS | ✓ | 40 | 580 | 160 | 2320 | 51⁄2 | 140 |

| *17⁄8 | 48 | 1.866 | 47.4 | SS | ✓ | 35 | 500 | 140 | 2000 | 65⁄8 | 170 |

| 2 | 50 | 2.012 | 51.1 | SS | ✓ | 30 | 430 | 120 | 1750 | 8 | 200 |

| 21⁄2 | 65 | 2.508 | 63.7 | SS | ✓ | 20 | 290 | 80 | 1160 | 117⁄8 | 300 |

| 3 | 80 | 3.024 | 76.8 | SS | ✓ | 15 | 218 | 60 | 870 | 133⁄4 | 350 |

| SS = Stainless steel braid | |||||||||||

*The 7⁄8", 13⁄8" and 17⁄8" hose sizes are only suitable for use with PTFE lined sanitary clamp (or triclover) end fittings and PTFE lined I-Line end fittings.

** The maximum working pressure (MWP) of a hose assembly is limited to the lowest of the MWP’s of either of the two end fittings, or of the hose itself as listed above. The MWP of the hose reduces as the operating temperature increases, consult Aflex Hose for guidance.

| Nominal hose bore size | Actual bore size | Bioflex Ultra grade | Helical wire | Maximum working pressure of hose | Burst pressure | Minimum bend radius | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | in | mm | bar | psi | bar | psi | in | mm | ||

| 3⁄8 | 9.5 | 0.382 | 9.7 | TO | - | 5 | 72 | 20 | 290 | 1⁄8 | 35 |

| 1⁄2 | 15 | 0.516 | 13.1 | TO | ✓ | 5 | 72 | 20 | 290 | 23⁄8 | 60 |

| 5⁄8 | 16 | 0.638 | 16.2 | TO | ✓ | 5 | 72 | 20 | 290 | 21⁄2 | 64 |

| 3⁄4 | 20 | 0.760 | 19.3 | TO | ✓ | 5 | 72 | 20 | 290 | 3 | 75 |

| *7⁄8 | 22 | 0.870 | 22.1 | TO | ✓ | 4 | 60 | 16 | 230 | 31⁄2 | 90 |

| 1 | 25 | 1.012 | 25.7 | TO | ✓ | 4 | 60 | 16 | 230 | 43⁄4 | 110 |

| 11⁄4 | 32 | 1.268 | 32.2 | TO | ✓ | 3 | 43 | 12 | 175 | 51⁄2 | 140 |

| *13⁄8 | 35 | 1.370 | 34.8 | TO | ✓ | 2 | 29 | 8 | 116 | 61⁄2 | 160 |

| 11⁄2 | 40 | 1.516 | 38.5 | TO | ✓ | 2 | 29 | 8 | 116 | 7 | 180 |

| *17⁄8 | 48 | 1.866 | 47.4 | TO | ✓ | 2 | 29 | 8 | 116 | 11 | 280 |

| 2 | 50 | 2.012 | 51.1 | TO | ✓ | 2 | 29 | 8 | 116 | 12 | 200 |

| TO = Tube only | |||||||||||

*The 7⁄8", 13⁄8" and 17⁄8" hose sizes are only suitable for use with PTFE lined sanitary clamp (or triclover) end fittings and PTFE lined I-Line end fittings.

** The maximum working pressure (MWP) of a hose assembly is limited to the lowest of the MWP’s of either of the two end fittings, or of the hose itself as listed above. The MWP of the hose reduces as the operating temperature increases, consult Aflex Hose for guidance.

Note: 21⁄2" & 3" tube only (TO grade) cannot be ordered as an assembly.

| EPDM rubber covered (RC/BK) grade hoses | Polypropylene braid (PB) grade hoses | Silicone rubber covered (SI) grade hoses | Stainless steel braid (SS) grade hoses | Tube only (TO) grade hoses | |

| Nominal bore size | 9.5 - 80 mm (0.375 - 3 in) | 15 - 80 mm (0.5 - 3 in) | 9.5 - 80 mm (0.375 - 3 in) | 9.5 - 80 mm (0.375 - 3 in) | 9.5 - 50 mm (0.375 - 2 in) |

| Actual bore size | 9.7 - 76.8 mm (0.382 - 3.024 in) | 13.1 - 76.8 mm (0.516 - 3.024 in) | 9.7 - 76.8 mm (0.382 - 3.024 in) | 9.7 - 76.8 mm (0.382 - 3.024 in) | 9.7 - 51.1 mm (0.382 - 2.012 in) |

| Length | 15 - 30 m (50 - 100 Ft) | 15 - 30 m (50 - 100 Ft) | 15 - 30 m (50 - 100 Ft) | 15 - 30 m (50 - 100 Ft) | 25 - 30 m (80 - 100 Ft) |

| Outside diameter | 15.5 - 92.8 mm (0.61 - 3.654 in) | 20.5 - 94.8 mm (0.8 - 3.732 in) | 15.5 - 92.8 mm (0.61 - 3.654 in) | 12.8 - 87.8 mm (0.5 - 3.457 in) | 12 - 58.9 mm (0.47 - 2.32 in) |

| Max. operating pressure | 80 bar (1160 psi) | 35 bar (500 psi) | 80 bar (1160 psi) | 80 bar (1160 psi) | 5 bar (72 psi) |

| Burst pressure | 60 - 500 bar (870 - 7,200 psi) | 40 - 140 bar (580 - 2,000 psi) | 60 - 500 bar (870 - 7,200 psi) | 60 - 500 bar (870 - 7,200 psi) | 8 - 20 bar (116 - 290 psi) |

| Certification and compliance | 3.1 Traceability, 3-A 62-02, Anti-static to BS5173 section 103.13 part 6.2 and 6.3, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), Fireproof to BS5173 section 103.13 part 6.2 and 6.3, ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class | 3.1 Traceability, 3-A 62-02, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class VI | 3.1 Traceability, 3-A 62-02, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class VI | 3.1 Traceability, 3-A 62-02, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class VI | 3.1 Traceability, 3-A 62-02, ATEX, EN16643:2016, EU Regulation 10/2011, FDA (materials), ISO 14001:2015, ISO 9001:2015, OHSAS 18001:2015, USP Class VI |

| Operating temperature | -40 °C to 150 °C (-40 °F to 302 °F) | -30 °C to 100 °C (-22 °F to 212 °F) | -73 °C to 240 °C (-100 °F to 400 °F) | -73 °C to 260 °C (-100 °F to 500 °F) | |

| Bend radius | 19 - 350 mm (0.75 - 13.75 in) | 38 - 350 mm (1.5 - 13.75 in) | 19 - 350 mm (0.75 - 13.75 in) | 19 - 350 mm (0.75 - 13.75 in) | 35 - 300 mm (1.375 - 12 in) |

| Weight per unit length | 0.22 - 4.3 kg/m (0.15 - 2.96 lb/ft) | 0.22 - 3.02 kg/m (0.15 - 2.02 lb/ft) | 0.22 - 4.3 kg/m (0.15 - 2.96 lb/ft) | 0.14 - 3.13 kg/m (0.09 - 2.1 lb/ft) | 0.06 - 1.25 kg/m (0.04 - 0.84 lb/ft) |

| Braid type | None | ||||

| Cover | EPDM | None | Silicone rubber | None | None |

| Hose external protection options | Protection coil, Safegard, Scuff rings | Protection coil, Safegard, Scuff rings | Protection coil, Safegard, Scuff rings | Protection coil, Safegard, Scuff rings | Protection coil, Safegard, Scuff rings |

| End fitting | 3-A sanitary fittings, 90° elbow fittings, BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, SMS and RJT fittings, Swivel flange fittings | 3-A sanitary fittings, 90° elbow fittings, BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, SMS and RJT fittings, Swivel flange fittings | 3-A sanitary fittings, 90° elbow fittings, BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, SMS and RJT fittings, Swivel flange fittings | 3-A sanitary fittings, 90° elbow fittings, BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, SMS and RJT fittings, Swivel flange fittings | 3-A sanitary fittings, 90° elbow fittings, BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, SMS and RJT fittings, Swivel flange fittings |

| Labelling options | Colour Coding, Standard | Colour Coding, Standard | Colour coding, Standard, Streamline tagging | Colour Coding, Standard | Colour Coding, Standard |

| Vacuum resistance | Usable at vacuum -0.9 bar up to 200 °C (392 °F) | Usable at vacuum -0.9 bar up to 200 °C (392 °F) | Usable at vacuum -0.9 bar up to 200 °C (392 °F) | Usable at vacuum -0.9 bar up to 200 °C (392 °F) | Usable at vacuum -0.9 bar up to 200 °C (392 °F) |

| Helical wire | Stainless steel 316 |

| Liner tube | PTFE |

| Braid | Polypropylene, Stainless steel |

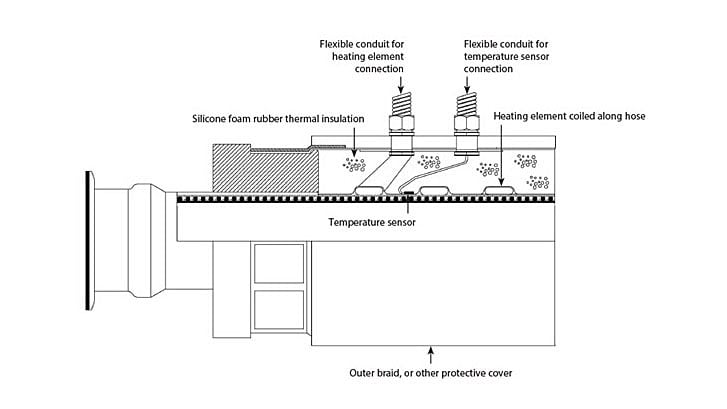

For use in applications where the temperature of the process fluid must be regulated as it passes through the hose. In some applications, an additional ‘melt out’ facility may also be required.

The heating element comprises self-regulating element spirally wrapped around the hose assembly. Self-regulating elements may require a sensor and controller if a specific maintain temperature is required. Please consult Aflex Hose for clarification. The power leads and (if applicable) temperature sensor leads emerge from the hose assembly at one end, through glands and conduits. The thermal insulation is foam rubber, silicone foam rubber. The outer cover may be a polypropylene braid or SS wire braid with a blue or black EPDM rubber cover.

Each hose is custom designed and built. Application details must be supplied by filling in an “ETH Hose Questionnaire”, available from the website. Generally, for hazardous areas, particularly “Zone 1”, the Self-Regulating type of heating element is employed, with or without a temperature sensor and control, and flameproof glands and conduit are also required. The watts per metre of the heating element, the pitch of the spiral on the hose, and the thickness of the thermal insulation are all calculated in accordance with established formulae to give the required maintained temperature.

As for Bioflex Ultra GP, SS in Specifications, except that the minimum bend radius is tripled and the outside diameter and weight are significantly increased in line with the particular design. The maximum length of a CH/ETH hose is 10m (33ft).

1” PTFE lined PN10 flange spigots on heated hoses can only have a maximum flare diameter of 50mm, not 63mm. If the hose is “hanging”, straight or at 90˚, under its own weight, special construction is required, so advise Aflex Hose accordingly. Minimum ETH Hose assembly length, when collars are used 1mtr.

| Hose | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Tube only -TO | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Stainless Steel - SS | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Rubber Covered - RC | ✔ | ✔ | ✔ | ✔ | |||||

| Polypropylene Braid - PB | ✔ | ✔ | |||||||

| Platinum Cured - SI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Braids | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Plastic Rubber option | ✔ | ✔ | ✔ | ||||||

| Aramid | ✔ | ||||||||

| Kynar Braid | ✔ | ||||||||

| Hastelloy Braid | ✔ | ||||||||

| Blue EPDM | ✔ | ✔ | ✔ | ||||||

| Black EPDM | ✔ | ✔ | ✔ | ||||||

| External protections | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Safeguard Protection Sleeve - SG | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Scuff Ring - SR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Protection Coil - PC | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Double Rubber Cover End Protection - RC300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Double Rubber Cover End Protection - DBK300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

|---|---|---|---|---|---|---|---|---|---|

| Swivel Flange Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Swivel Flange Fittings - Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Male Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Male Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Female Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Female Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Sanitary Triclamp Fittings PTFE Lined and Flared | ✔ | ✔ | ✔ | ||||||

| Sanitary Triclamp Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary & Mini Sanitary | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary Triclamp Fittings - 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| DIN 11851 / SMS Fittings - PTFE Lined | ✔ | ✔ | ✔ | ||||||

| DIN 11851 Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| RJT Female Fittings - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| BSP & NPT Threaded Fittings - NPT & BSPT Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| BSP & NPT Threaded Fitting - BSP 60° Cone seat female fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| JIC Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| PTFE Dip Pipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 3-A Sanitary Fittings | ✔ | ✔ | ✔ | ✔ | |||||

| 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Grooved Standpipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| IDF Female / Male - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| ENCAP Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| PTFE Tail or Hydraulic Fittings | ✔ | ✔ | ✔ | ||||||

| PTFE Tail Fittings | ✔ | ✔ | ✔ | ✔ |

Specify all requirements in order shown below:

| Example | ||

|---|---|---|

| Written description | 4 off x 1” bore Bioflex Ultra, AS, SS, RC, DRC-300 hose x 3.00 metres long. Both ends non-lined ANSI 150# S/S Flanges |

|

| Part numbers | 4 off Part No. 16-BFXU/AS-RC-00-3.00m-12-12, with DRC 300 at both ends. | |

Special requirements:

Specify full written description on enquiry or purchase order:

| PTFE liner | Braids | Rubber covers |

|---|---|---|

| Natural (GP) | 316 stainless steel (SS) | Platinum cured silicone |

| Antistatic (AS) | Polypropylene (PB) | Blue EPDM rubber cover (RC) |

| Black EPDM rubber cover (BK) |

External protections available – see braid, covers and end fittings page.

LISTED MINIMUM LENGTHS DO NOT INCLUDE FITTINGS.

Hose length + end fittings = Total hose assembly length (sealing face to sealing face)

Lengths made to customer requirement. Tolerance +2 %/-0 %. Closer tolerances available to special order.

| Nominal Size of Hose | Minimum Hose Length Between Fittings | Maximum Hose Assembly Length Longer lengths may be available by special order |

||

|---|---|---|---|---|

| Used Straight | Flexed Through 90° | |||

| All Grades | TO, KYB Grades | SS, PB RC Grades | ||

| inches (mm) | inches (mm) | inches (mm) | inches (mm) | Metres (ft) |

| 3/8 (10) | 3 (75) | 3.00 (75) | 3.00 (75) | 100 (30) |

| 1/2 (15) | 3 (75) | 3.00 (75) | 3.00 (75) | 100 (30) |

| 5/8 (16) | 3 (75) | 4.00 (100) | 3.00 (75) | 100 (30) |

| 3/4 (20) | 3 (75) | 4.72 (120) | 4.00 (100) | 100 (30) |

| 7/8 (22) | 3 (75) | 5.71 (145) | 4.00 (100) | 100 (30) |

| 1 (25) | 3 (75) | 6.89 (175) | 4.33 (110) | 100 (30) |

| 11/4 (32) | 4 (100) | 8.66 (220) | 6.30 (160) | 100 (30) |

| 13/8 (35) | 4 (100) | 10.04 (255) | 7.48 (190) | 100 (30) |

| 11/2 (40) | 4 (100) | 11.22 (285) | 8.66 (220) | 100 (30) |

| 17/8 (48) | 4 (100) | 17.32 (440) | 11.81 (300) | 100 (30) |

| 2 (50) | 4 (100) | 18.70 (475) | 12.40 (315) | 100 (30) |

| 21/2 (65) | 4 (100) | 27.95 (710) | 18.70 (475) | 60 (18) |

| 3 (80) | 4 (100) | 32.48 (825) | 21.65 (550) | 50 (15) |

Large range of ‘standard’ end fittings available.

Special order—non-standard grades of SS or materials such as Hastelloy or Monel.

| Specification Equivalents | |||

|---|---|---|---|

| Grade | BS British Standard |

AISI American Standard or C = Casting Grade |

EN European Norm |

| 316L SS | BS 316 S11 | AISI 316 L | EN1.4404 |

| 316C SS | BS 316 C16 | CF8M | EN 1.4408 |

| 304 SS | BS 304 S15 | AISI 304 | EN 1.4301 |

Low shear, zero pulsation and self-draining pump certified with EHEDG Type EL Class I and EHEDG Type EL Aseptic Class I.

Pumps - sine pumps

Convoluted bore hose for transferring process fluids where a smooth bore is not a specific requirement.

Flexible hose assemblies

Smooth bore hose for chemical and other fluid flow applications where rough usage may occur.

Flexible hose assemblies

Smooth bore hose for replacing silicone rubber hoses for improved compatibility and cleanability.

Flexible hose assemblies

To order a product or ask a question