- Case Study

South African Breweries turns to Certa pumps for yeast cropping

South African Breweries purchases MasoSine Certa 400 based on energy consumption comparisons

South African Breweries purchases MasoSine Certa 400 based on energy consumption comparisons

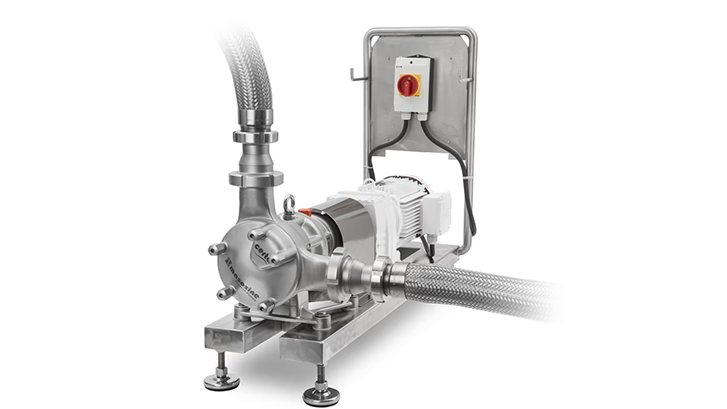

South African Breweries (SAB) has added to an existing process by introducing three MasoSine Certa 400 pumps from Watson-Marlow Fluid Technology Solutions (WMFTS). Intended for use as part of a yeast cropping application, SAB made the purchase decision after assessing energy consumption comparisons between Certa pumps and comparable lobe or circumferential piston pumps.

South Africa has been home to SAB since the company’s humble beginnings over a century ago during Johannesburg’s pioneering gold rush days. Since then, SAB has grown into a landmark South African organisation, with brands such as Castle Lager, and belongs to the AB InBev Group, which owns globally established brands such as Becks, Budweiser, Corona and Stella Artois.

WMFTS South Africa visited SAB to fulfil an enquiry regarding a project that involved the use of pumps for yeast-related processes. Having in mind previous success with Certa pumps for yeast cropping at other brewery sites in South Africa, such as SAB Chamdor and Rosslyn, WMFTS was able to support these project examples with energy and carbon dioxide (CO2) emissions savings calculations that were difficult to ignore. As a result, SAB duly placed an order for three MasoSine Certa 400 pumps.

Notably, the energy efficient pumping action of the Certa pumps, which SAB controls via its in-house SCADA system, will contribute to the brewery achieving AB InBev’s 100+ sustainability target.

The yeast application at SAB, with a viscosity of 2000 cP, demands power requirements from the MasoSine Certa of 3.1 kW, which compares favourably to a comparable lobe or circumferential piston pump, which would typically require 6kW.

“The yeast application at SAB, with a viscosity of 2000 cP, demands power requirements from the MasoSine Certa of 3.1 kW, which compares favourably to a comparable lobe or circumferential piston pump, which would typically require 6kW.”

The energy savings presented to SAB were based on the pumps running for four hours a day, seven days per week, although this will of course be variable. Energy was based on a price per kWh of €0.15. The yearly (50 weeks) electricity costs for a Certa 400 pump can therefore be shown as €651, against €1, 260 for a competitor pump, giving an annual saving of €609 per pump.

The result is equally impressive for CO2 emissions, just 2625.7 kg for a Certa pump versus 5082 kg for a lobe or circumferential piston pump.

SAB will also gain from many other MasoSine Certa pump advantages:

The average yeast harvest time for one yeast strain was reduced by 56%.

Case Study

The pump is used to transfer viscous yeast from multiple tanks located around the brewery.

Case Study

Certa Sine pumps have replaced rotary lobe pumps at the family-owned Hofmann brewery in Germany.

Case Study

Updated

Low shear, virtually no pulsation EHEDG Type EL Aseptic Class I certifed pump. Up to 50 % less power than other pumps.

Pumps - sine pumps

To order a product or ask a question call +65 6455 7411 or