- Case Study

First Milk enhances cheese yield and reduces maintenance with Certa Sine pumps

First Milk maximises quality, cuts cost and increases output with two Certa Sine pumps

First Milk maximises quality, cuts cost and increases output with two Certa Sine pumps

Increasing cheese yield while retaining fat and moisture was an important priority for First Milk when it needed to select new pumps capable of supporting an increase in production at its Haverfordwest Creamery in Wales.

Increasing cheese yield while retaining fat and moisture was an important priority for First Milk when it needed to select new pumps capable of supporting an increase in production at its Haverfordwest Creamery in Wales.

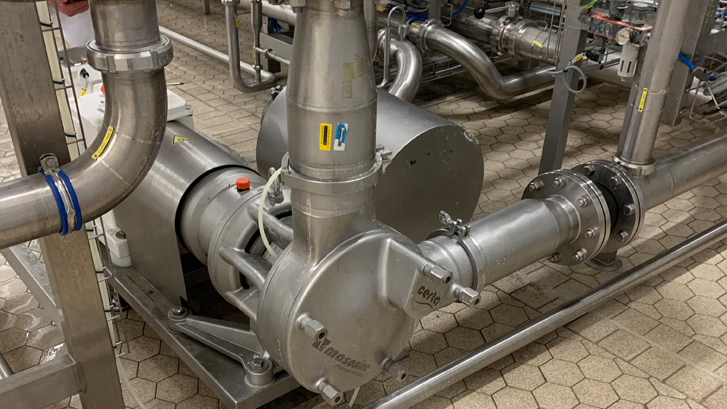

As part of a major investment into its Haverfordwest Creamery, First Milk needed to replace rotary lobe pumps with more efficient and lower-maintenance hygienic pumps.

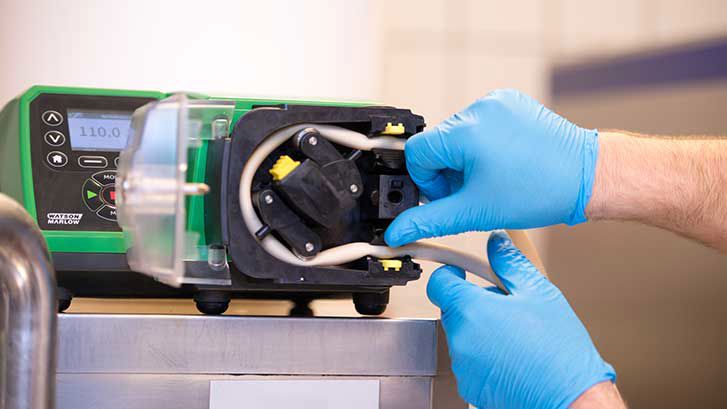

As the dairy farmer-owned co-operative was increasing its output, it needed to invest in pumps which would minimise damage to curds, as cheese yield decreases with the degradation of curds. After seeing a video that demonstrated how Certa Sine pumps from MasoSine gently transferred chicken breast fillets, and witnessing a live demonstration at the Haverfordwest site, First Milk installed two Certa 600 pumps to work alongside each other serving 10 specialised cheese vats.

Since their installation in 2022, the Certa pumps have played a key role in an increase in production at the Haverfordwest site as their gentle handling pump action ensures the curds and whey mixture is carefully transferred from coagulation vats to the draining stage. The low shear handling provided by the two Certa pumps results in minimal degradation of cheese curds during transfer.

The Certa pumps have succeeded in reducing cheese fines and retaining fat and moisture within the cheese curds to ensure high product integrity for First Milk, which won 12 awards at the 2025 British and Irish Cheese Awards. The low shear pumping also prevents aeration and foaming during the transfer of the curds-whey mixture.

By preserving the integrity of the curds, the Certa pumps ensure a consistently high-quality product from First Milk, which manufactures award-winning cheese, specialist chilled dairy products, whey and dairy ingredients which it sells into the B2B market.

Nigel Roberts, Engineering Manager at First Milk Ltd in Haverfordwest, said: “Low shear, low maintenance and Clean-In-Place were the most important points about the Certa pumps. Significant investment in many parts of the plant was necessary during 2022 to achieve a capacity increase. The existing lobe pumps were proving very expensive to service and we needed to replace them.

“After we saw a video how Certa pumps successfully transferred chicken breasts, it got us thinking that the pumps could be as equally gentle with our curd. We had a site demonstration and the installing contractor confirmed the Certa pumps had been seen operating successfully at a dairy in Ireland.

“We want to maintain moisture retention and minimise whey fat losses in the curd particles. If a pump damages the curds, the result may affect yields and an inability to meet a customer’s profile specification. The primary reasons for replacing the lobe pumps during the plant upgrade with the Certa pumps was cheese yield, fat and moisture retention, but maintenance was also an issue.”

“The primary reasons for replacing the lobe pumps during the plant upgrade with the Certa pumps was cheese yield, fat and moisture retention, but maintenance was also an issue. The Certa pumps have been easy to maintain.”

The two Certa 600 pumps have reduced maintenance downtime, compared to the previously used lobe pumps, and are used for 22 hours a day, every day apart from 11 days of planned maintenance downtime at Haverfordwest Creamery in Wales since they were installed in 2022.

Certa pumps are also energy efficient. At First Milk’s site, each Certa pump is running at 63% of its capacity to transfer the curds and whey mixture.

Nigel Roberts, Engineering Manager at First Milk Ltd in Haverfordwest, added: “When we had extra cheese vats installed, we looked at replacing the rotary lobe pumps because they were proving very expensive to service. They couldn’t be serviced on site and the cost was getting very high.

“The only part we've changed so far is the food safe gates. We have flow metres online so you can see if efficiency does drop off. We have experienced good seal life as well. The Certa pumps have been easy to maintain. Oil seals had become an issue on the gearboxes of the rotary lobe pumps, thereby prompting maintenance/swap outs, but we don’t experience that with the Certa pump.”

First Milk has also benefited from enhanced process efficiency with the Certa’s full Clean-In-Place (CIP) capability and savings in chemical and water usage and disposal. A hygienic pump design is essential to reduce cleaning of the entire system and reduce the amount of cleaning agents needed.

The gentle, energy-efficient pumping technology of MasoSine has proven to be an asset in the ongoing success of First Milk’s creamery in Haverfordwest.

Nigel Roberts, Engineering Manager at First Milk Ltd, added: “CIP efficiency is important and the Certa pumps clean very well. During CIP testing, it was essential the plant was cleaned sufficiently and verification of the clean confirmed.

“The planned maintenance is quite simple on them, we carry out condition monitoring, and are yet to find any issues, replacement of the gate can easily be pre-empted.

“Efficient transfer and suction are important because we have a set time for each vat to fill, go through the coagulation process and empty, and the pumps have got to do their job and not hold the process up.”

From producing 2,000 litre vat production rates to 100,000 tonnes of cheese per year from 830 million litres of milk, WMFTS supplies pumping and hose solutions for dairy companies of all sizes.

Andrew Freeman, Sales Engineer for Food and Beverage and Clean Process at WMFTS, said: “The low shear was very important for First Milk because of the quality of cheese curds and the potential to reduce the number of cheese fines. Reducing the downtime was also important as was the overview training we gave pre-installation on site for two shifts at First Milk. Employees at First Milk were able to learn about best practices and were supervised while they stripped the pump and reassembled.

“As well as the product benefits, we provide unparalleled specialist support. First Milk has had support on the ground from MasoSine and Watson-Marlow engineers post-installation and guidance on best practices, such as how to avoid common mistakes, to give First Milk the best possibility of pump longevity.”

Case Study

Certa clear winner in pump tests at Emmi in Switzerland.

Case Study

Case Study

Fast-growing cheese producer switches from centrifugal pump to Certa sine pump.

Case Study

Case Study

Certa three times more energy efficient than pneumatic pumps at transferring double and single...

Case Study

Case Study

View full case study on peristaltic pumps for hot sauce dosing.

Case Study

To order a product or ask a question call +63 2 295 6392 or