- Insight

Maximising productivity, minimising impact: how to choose the right pumps for efficient and sustainable mining

Expert Q+A

Expert Q+A

If mining companies are to increase production while minimising downtime and their environmental impact, choosing the right pumps is critically important in 2025. As well as limiting costs, other considerations such as water scarcity, power consumption and meeting regulations are also priorities.

Wilfried Staijen (Mining Sector Specialist at Watson-Marlow Fluid Technology Solutions) has visited mining and construction sites around the world to advise on how WMFTS products can be applied to improve plant productivity. Wilfried explains here which pumps can be applied to improve plant productivity, how to overcome challenges such as water scarcity and lowering power consumption, while minimising maintenance and pump downtime.

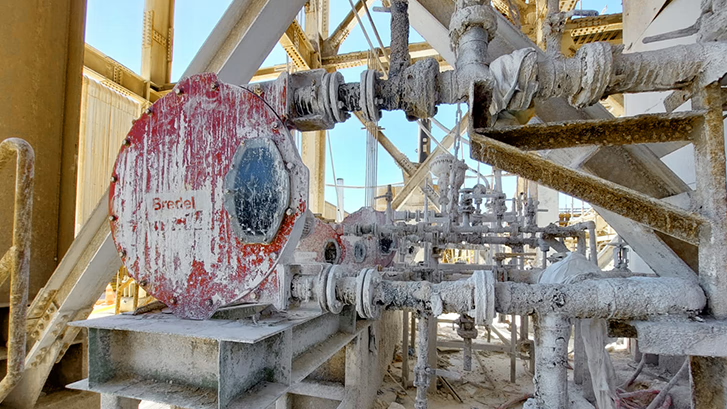

First of all, water availability. If you go to Chile, South Africa or Australia, water scarcity is a challenge for mining companies. In some cases, they pump desalinated sea water into the mountains or deserts where the mining sites are located. A progressive cavity pump and centrifugal pump has seals inside and those seals need to be flushed continuously with a lot of fresh water, and that is a problem for certain mines in areas where there is water scarcity. These pumps need clean water and not sea water too, and the mining companies must treat the used water to use it again, and the environment at the site becomes muddy. But if you look at the design of peristaltic pumps such as the Bredel hose pump, it doesn’t have a mechanical seal. With peristaltic pumps, you don’t need to flush them so that is a major saving on fresh water. A Bredel pump can transfer a product with solids up to 80%, and that means the water content is much lower than what it must be for a centrifugal pump.

Then there is power consumption: if you look at centrifugal pumps they need 50-60% more motor power to operate at the same flow as the peristaltic pump. Peristaltic pumps take up 40-50% of pump of power compared to the centrifugal pump. When you change the speed of a centrifugal pump it moves away from the best efficiency point and the power consumption is even more. With the Bredel, when you bring down the pump speed you also consume less power. Bredel is a lot more efficient with electricity than a centrifugal pump, which allows mining companies to save on power and diesel to generate the electricity on site.

Leakage, and mining’s impact on the local environment, is becoming increasingly important. When you walk on a mining site you will see pumps leaking water, slurry and reagents. Our pumps can do the dosing job without a problem and when the tubing in the pumphead eventually fails and needs replacing on a Qdos pump, it is detected by the controller and the pump stops so there is no leakage of chemical reagents, it stays in the pump. The Bredel also has a pump housing and when the hose fails, the chemical remains inside, so it is contained.

Having a robust and reliable pump is important. The centrifugal pump at some point will stop pumping and it will not deliver the slurry to the analyser, where as the peristaltic will always deliver. I have seen centrifugal pumps used for sampling at mine sites and they were leaking water, which created a dangerous situation.

Costs are always a priority. Overdosing reagents is expensive, while underdosing results in the loss of valuable minerals and an extra expensive step in the process to extract the minerals from the slurry. Watson-Marlow cased pumps and Qdos chemical metering pumps provide accurate and controlled dosing of chemical reagents, which ensures that mining companies do not overdose in their processes and so make savings on chemical reagents costs. The precise dosing capabilities of Qdos and Watson-Marlow peristaltic pumps ensure that only the necessary amount of reagents are used. This minimises chemical waste, lowers effluent treatment costs, and reduces the risk of spills that could contaminate soil and water.

Mining is a 24/7 process: the ore comes in and it leaves the plant, it never stops. If production stops it is a major issue and it can take days, or weeks to get the process up again. If a mining company stops the process, it has to clean and drain the system completely, and empty all the tanks and vessels. But all critical processes have a back-up process line. When the duty pump fails, the backup pump will take over. If the standby pump fails, then you have a serious problem. It is therefore important that the defective pump is repaired quickly and safely, which is easily done with Bredel pumps. If the process has an uncontrolled breakdown it would cost millions of dollars and weeks to ramp up again.

There are other consequences of a pump failure. Once I saw at a customer’s site how a competitor pump installed under a thickener had a leakage, and the whole plant got flooded with sludge and slurry. Everything needed to be cleaned, and motors and equipment needed to be repaired. It can lead to a costly clean up and buying new parts.

The number of staff on mining sites is being minimised as much as possible, and the staff might not be trained enough into how to run and maintain the equipment. Failure to detect maintenance issues can result in the pump breaking down overnight, leaving the morning shift with an empty tank and extensive damage to the pump. With a less skilled workforce, it is important to have reliable and long-lasting products.

At Cornish Metals’ South Crofty tin mine in England, eight Bredel hose pumps are transferring sludge at the mine’s water treatment plant. Three Qdos chemical metering pumps also reliably dose hydrogen peroxide to oxidise the contaminated metals in the mine water at the water treatment plant. By treating the contaminated mine water which has been pumped out of a flooded mineshaft, Cornish Metals has hugely improved the quality of water of a nearby river.

Concentrated mineral slurries are pumped through a filter press where a filter cake is formed that is transported to the smelters for further processing. The less water in the slurry, the smaller the filters can be and the smaller the filter press pumps. By increasing the solid content in the thickeners, less water passes through the pump and filter, but traditional slurry pumps can only pump 40% solids content. The Bredel hose pump, with its peristaltic design, can pump up to 80% dry matter. So by using a Bredel pump, you can ultimately save on filter capacity. The Bredel pump can also be controlled with a frequency controller. The volumetric capacity remains 100%, regardless of the speed of the pump. A traditional slurry pump cannot run with frequency control, because it then deviates from the ‘best efficiency point’ and does not perform profitably or even fails in functioning.

Sampling of slurries is one. In the flotation cells mining companies continuously take samples of the slurries to measure the copper or gold content for example, and if they have enough reagent to extract all the copper or gold. That slurry content contains solids, reagents, air and the line length can be long in a harsh environment. Sometimes you need a positive suction of five or six metres to transfer up. The line length and suction are different per application. If the process is not under control, the slurry will have more solids, or it will be more viscous, and they will have to adjust the dosing of the reagents. Those parameters have an impact on a pump’s performance but with a Bredel pump it doesn’t really matter because it is self-priming and it can pump air, solids and viscous products up to 16 bar. Inconsistency in the slurry does not impact the Bredel pump’s performance over a 24/7 operation.

Watson-Marlow and Qdos pumps are used for reagents dosing for their accuracy, easy control by VFD/PLC, with easy maintenance and short downtime.

Back fill is another application where Bredel pumps are being used in. When mining companies extract the minerals, the waste is a mud slurry which goes into a dam and they mix the slurry with cement and pump it back into the opening of the mine to reinforce it.

Again, it is high solid content. Again, it is a challenging high solid content application, but we have been successful at sites in Brazil and Scandinavia where they are pumping tailings with cement.

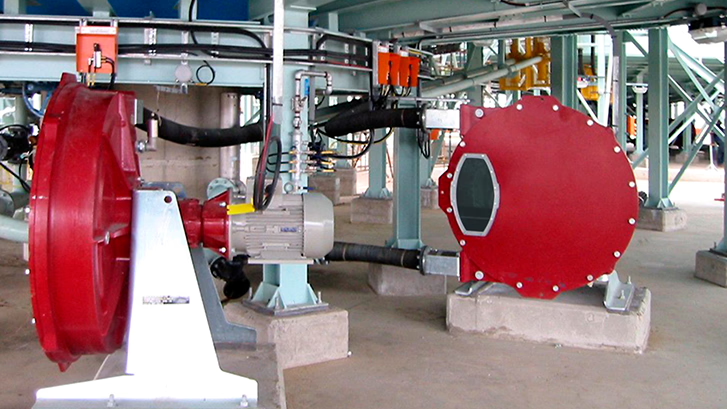

The mining industry demands maximum output from its processes and does not accept unexpected failures. The Heavy Duty pump has increased safety features and improved durability thanks to its bearing construction, reinforced flange brackets and protection of the inspection window. This in combination with the excellent pump hose guarantees maximum uptime and a continuous production process.

Because on-site safety requirements are becoming increasingly strict, the frame is equipped with an extra reinforced base so that the entire pump unit can be lifted and moved with a forklift truck, which avoids situations of dangerous lifting with chains and hoists.

Wilfried Staijen is the Mining Sector Specialist at Watson-Marlow Fluid Technology Solutions, after joining Bredel Hose Pumps in 1991. Wilfried is our heavy industry pump specialist who can explain to customers how peristaltic pumps transform slurry handling with efficiency, reliability, and zero seal failures.

Product

The Bredel Heavy Duty pump provides an enhanced level of safety and reliability for harsh environments.

Pumps - hose pumps

Product

Flow rates to 17,520 L/h (4,623 USGPH) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

Product

Flow rates to 2,000 ml/min (31.7 USGPH) and pressures up to 7 bar (100 psi).

Pumps - cased pumps

Product

Flow rates to 3.5 L/min (55 USGPH) and pressures up to 7 bar (100 psi). Precise 2,200:1 speed control range.

Pumps - cased pumps

To order a product or ask a question call +353 (21) 4757 030 or