弹性软管组件

Hyperline FX

概览

Hyperline FX

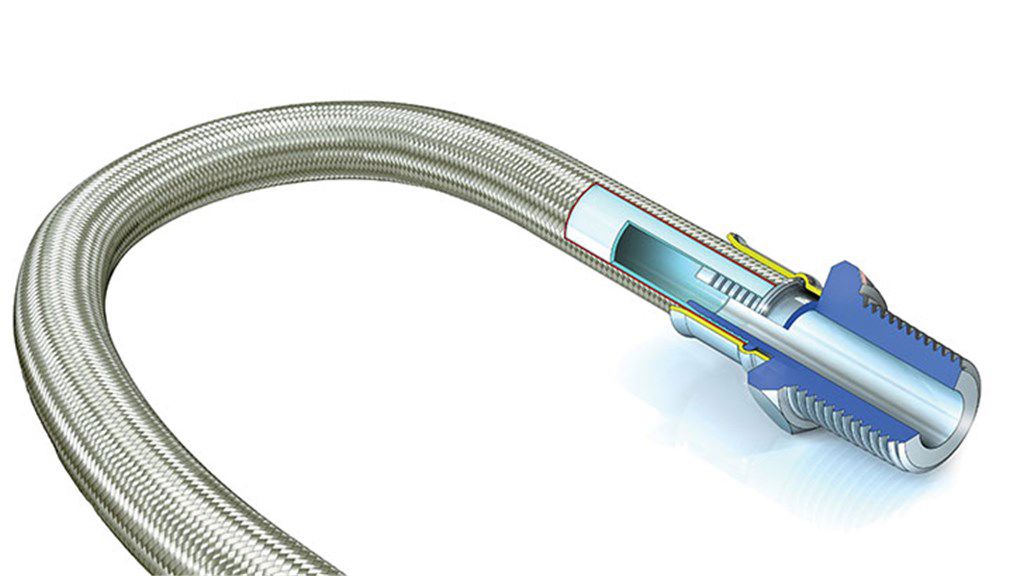

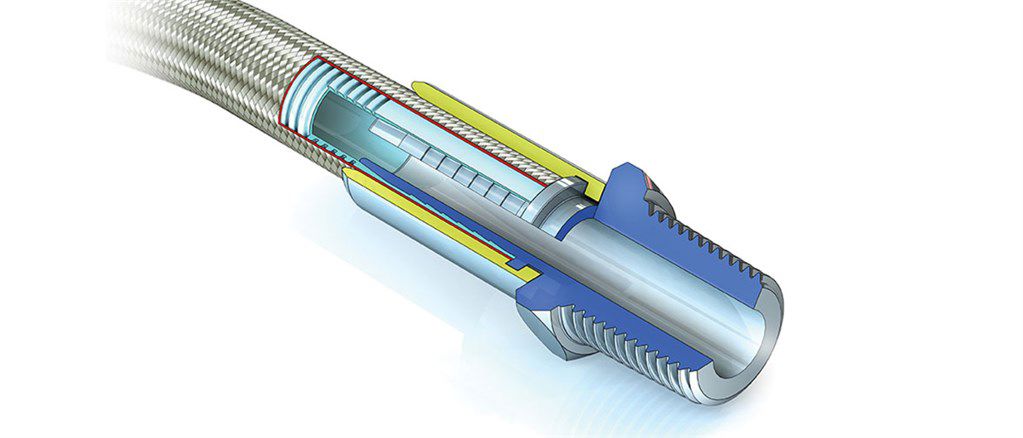

PTFE 内衬软管,用于汽车和通用应用

由于获得专利的 PTFE 内衬设计,Hyperline FX 软管比 Smoothbore 软管更加灵活,因此在需要提高灵活性的应用中,它是一种更好的替代产品。特别适合空间要求有限的汽车软管和航空航天软管应用中需求旺盛的紧凑型配置。

特点和优势

- 专利内衬提供无与伦比的灵活性和防扭结性能

- 出色的耐化学性

- 平滑孔径可实现快速流动和易于清洁

- 耐流体和气体扩散

技术摘要

| 标称孔径 | 6 - 25 mm |

| 标称孔径 | 0.25 - 1 in |

| 外径 | 9 - 31.7 mm |

| 外径 | 0.354 - 1.25 in |

| 最大工作压力 | 88 bar |

| 最大工作压力 | 1280 psi |

| 认证与合规 | 3.1 可追溯性, EN16643:2016, FDA(材料), SAE J1737, TS 16949:2016 |

| 弯曲半径 | 19 - 150 mm |

| 弯曲半径 | 0.75 - 6 in |

| Braid 类型 | 无 |

| 盖 | 无 |

“技术摘要”表列出了该范围内可用的功能。请参阅“规格”选项卡了解型号特定信息。

性能

Hyperline FX 聚醯胺纤维编织 (AM) 级软管 性能

| 软管孔径 | 实际软管孔径 | 软管 | 软管或编织层的外径 | 最小弯曲半径 | 最大工作压力 (MWP) | 爆破压力 | 单位长度的重量 | *零件号 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | 标号尺寸 | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.250 - 0.280 | 6.35 - 7.12 | AM | 0.360 - 0.400 | 9.14 - 10.16 | 1 1/2 | 38 | 77 | 1116 | 231 | 3350 | 0.056 | 0.038 | 92-100-04-01-55-01 |

| 5/16 | 5 | 0.290 - 0.320 | 7.36 - 8.13 | AM | 0.440 - 0.480 | 11.17 - 12.19 | 1 1/2 | 38 | 74 | 1073 | 222 | 3220 | 0.075 | 0.050 | 92-100-05-01-55-01 |

| 3/8 | 6 | 0.376 - 0.406 | 9.55 - 10.32 | AM | 0.515 - 0.555 | 13.08 - 14.10 | 2 | 50 | 70 | 1015 | 210 | 3046 | 0.100 | 0.094 | 92-100-06-01-55-01 |

| 1/2 | 8 | 0.515 - 0.545 | 13.08 - 13.85 | AM | 0.655 - 0.695 | 16.64 - 17.66 | 3 | 76 | 52 | 754 | 156 | 2263 | 0.140 | 0.094 | 92-100-08-01-55-01 |

| 5/8 | 10 | 0.635 - 0.665 | 16.13 - 16.89 | AM | 0.815 - 0.855 | 20.70 - 21.72 | 4 | 100 | 44 | 638 | 132 | 1915 | 0.204 | 0.137 | 92-100-10-01-55-01 |

| 3/4 | 12 | 0.760 - 0.790 | 19.30 - 20.07 | AM | 0.946 - 0.986 | 24.03 - 25.05 | 5 | 126 | 36 | 522 | 108 | 1566 | 0.236 | 0.158 | 92-100-12-01-55-01 |

| 1 | 16 | 1.005 - 1.035 | 25.52 - 26.29 | AM | 1.233 - 1.273 | 31.32 - 32.34 | 6 | 150 | 35 | 507 | 105 | 1523 | 0.354 | 0.237 | 92-100-16-01-55-01 |

*对于防静电等级,在 3 位数的零件号中添加 10,例如 92-100- 变为 92-110。

上表中的性能测试结果是在环境温度、受控实验室环境下以水为介质所得出。我们建议客户对软管进行严格的应用性能测试,在一定时间内以实际工作条件对软管进行验证。

Hyperline FX 不锈钢编织 (SS) 级软管 性能

| 软管孔径 | 实际软管孔径 | 软管 | 软管或编织层的外径 | 最小弯曲半径 | 最大工作压力 (MWP) | 爆破压力 | 单位长度的重量 | *零件号 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | 标号尺寸 | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.250 - 0.280 | 6.34 - 7.12 | SS | 0.355 - 0.395 | 9.02 - 10.04 | 3/4 | 19 | 110 | 1595 | 330 | 4786 | 0.092 | 0.062 | 92-100-04-01-02 |

| 5/16 | 5 | 0.302 - 0.328 | 7.66 - 8.33 | SS | 0.424 - 0.458 | 10.77 - 11.63 | 3/4 | 19 | 105 | 1522 | 315 | 4569 | 0.126 | 0.084 | 92-100-05-01-02 |

| 3/8 | 6 | 0.376 - 0.406 | 9.54 - 10.32 | SS | 0.502 - 0.542 | 12.75 - 13.64 | 1 | 25 | 100 | 1450 | 300 | 4351 | 0.160 | 0.151 | 92-100-06-01-02 |

| 1/2 | 8 | 0.515 - 0.545 | 13.07 - 13.85 | SS | 0.655 - 0.695 | 16.64 - 17.66 | 1 1/2 | 38 | 75 | 1087 | 225 | 3263 | 0.225 | 0.151 | 92-100-08-01-02 |

| 5/8 | 10 | 0.635 - 0.665 | 16.12 - 16.89 | SS | 0.810 - 0.850 | 20.57 - 21.59 | 2 | 50 | 62 | 899 | 186 | 2698 | 0.336 | 0.226 | 92-100-10-01-02 |

| 3/4 | 12 | 0.760 - 0.790 | 19.30 - 20.07 | SS | 0.950 - 0.990 | 24.13 - 25.15 | 2 1/2 | 63 | 52 | 754 | 156 | 2263 | 0.383 | 0.257 | 92-100-12-01-02 |

| 1 | 16 | 1.005 - 1.035 | 25.52 - 26.29 | SS | 1.227 - 1.269 | 31.15 - 32.23 | 3 | 75 | 50 | 725 | 150 | 2176 | 0.540 | 0.362 | 92-100-16-01-02 |

*对于防静电等级,在 3 位数的零件号中添加 10,例如 92-100- 变为 92-110。

上表中的性能测试结果是在环境温度、受控实验室环境下以水为介质所得出。我们建议客户对软管进行严格的应用性能测试,在一定时间内以实际工作条件对软管进行验证。

Hyperline FX 仅软管 (TO) 级软管 性能

| 软管孔径 | 实际软管孔径 | 软管 | 软管或编织层的外径 | 最小弯曲半径 | 最大工作压力 (MWP) | 爆破压力 | 单位长度的重量 | *零件号 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | 标号尺寸 | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.252 - 0.278 | 6.39 - 7.06 | 至 | 0.326 - 0.368 | 8.28 - 9.35 | 1 1/2 | 38 | 6 | 87 | 18 | 261 | 0.041 | 0.027 | 92-100-04 |

| 5/16 | 5 | 0.308 - 0.333 | 7.84 - 8.46 | 至 | 0.382 - 0.424 | 9.72 - 10.77 | 1 1/2 | 38 | 6 | 87 | 18 | 261 | 0.056 | 0.037 | 92-100-05 |

| 3/8 | 6 | 0.381 - 0.407 | 9.69 - 10.34 | 至 | 0.475 - 0.511 | 12.06 - 12.98 | 2 | 50 | 6 | 87 | 18 | 261 | 0.070 | 0.047 | 92-100-06 |

| 1/2 | 8 | 0.525 - 0.550 | 13.33 - 13.97 | 至 | 0.620 - 0.668 | 15.77 - 16.97 | 3 | 76 | 6 | 87 | 18 | 261 | 0.110 | 0.074 | 92-100-08 |

| 5/8 | 10 | 0.639 - 0.665 | 16.25 - 16.89 | 至 | 0.770 - 0.811 | 19.55 - 20.60 | 4 | 100 | 6 | 87 | 18 | 261 | 0.161 | 0.108 | 92-100-10 |

| 3/4 | 12 | 0.765 - 0.795 | 19.42 - 20.20 | 至 | 0.895 - 0.941 | 22.73 - 23.90 | 5 | 126 | 6 | 87 | 18 | 261 | 0.179 | 0.120 | 92-100-12 |

| 1 | 16 | 1.005 - 1.035 | 25.77 - 26.55 | 至 | 1.165 - 1.215 | 29.58 - 30.86 | 6 | 150 | 6 | 87 | 18 | 261 | 0.268 | 0.180 | 92-100-16 |

*对于防静电等级,在 3 位数的零件号中添加 10,例如 92-100- 变为 92-110。

上表中的性能测试结果是在环境温度、受控实验室环境下以水为介质所得出。我们建议客户对软管进行严格的应用性能测试,在一定时间内以实际工作条件对软管进行验证。

规格

技术规格

| Hyperline FX 聚醯胺纤维编织 (AM) 级软管 | Hyperline FX 不锈钢编织 (SS) 级软管 | Hyperline FX 仅软管 (TO) 级软管 | |

| 标称孔径 | 6 - 25 mm (0.25 - 1 in) | 6 - 25 mm (0.25 - 1 in) | 6 - 25 mm (0.25 - 1 in) |

| 实际孔径 | 6.8 - 26 mm (0.27 - 1.023 in) | 6.8 - 26 mm (0.27 - 1.023 in) | 6.8 - 26 mm (0.27 - 1.023 in) |

| 长度 | 18 m (60 ft) | 18 m (60 ft) | 18 m (60 ft) |

| 外径 | 9.6 - 31.7 mm (0.378 - 1.25 in) | 9.6 - 31.7 mm (0.378 - 1.25 in) | 9 - 30.3 mm (0.354 - 1.193 in) |

| 最大工作压力 | 62 bar (900 psi) | 88 bar (1280 psi) | 4 bar (60 psi) |

| 爆破压力 | 84 - 186 bar (1200 - 2,700 psi) | 120 - 264 bar (1740 - 3,840 psi) | 6 - 12 bar (87 - 180 psi) |

| 认证与合规 | 3.1 可追溯性, EN16643:2016, FDA(材料), SAE J1737, TS 16949:2016 | 3.1 可追溯性, EN16643:2016, FDA(材料), SAE J1737, TS 16949:2016 | 3.1 可追溯性, EN16643:2016, FDA(材料), SAE J1737, TS 16949:2016 |

| 工作温度 | -40 °C 至 180 °C (-40 °F 至 356 °F) | -73 °C 至 260 °C (-100 °F 至 500 °F) | -73 °C 至 260 °C (-100 °F 至 500 °F) |

| 弯曲半径 | 38 - 150 mm (1.5 - 6 in) | 19 - 75 mm (0.75 - 3 in) | 38 - 150 mm (1.5 - 6 in) |

| 单位长度的重量 | 0.056 - 0.354 kg/m (0.038 - 0.237 lb/ft) | 0.092 - 0.54 kg/m (0.062 - 0.362 lb/ft) | 0.041 - 0.268 kg/m (0.027 - 0.18 lb/ft) |

| Braid 类型 | 无 | ||

| 盖 | 无 | 无 | 无 |

| 端接头 | BSP 和 NPT 螺纹接头, DIN 11851 接头, ENCAP 端接头, JIC 接头, PTFE 水封管接头, 卫生级 Triclamp 接头, 快装接头, 旋转法兰接头 | BSP 和 NPT 螺纹接头, DIN 11851 接头, ENCAP 端接头, JIC 接头, PTFE 水封管接头, 卫生级 Triclamp 接头, 快装接头, 旋转法兰接头 | BSP 和 NPT 螺纹接头, DIN 11851 接头, ENCAP 端接头, JIC 接头, PTFE 水封管接头, 卫生级 Triclamp 接头, 快装接头, 旋转法兰接头 |

| 耐真空度 | 耐真空度为 -0.9 bar,最高可达 150 °C (302 °F) |

主要材料

| 衬套管 | 天然 PTFE, 防静电 PTFE |

| 编织 | 不锈钢, 聚醯胺纤维 |

文档

宣传手册

-

Hyperline FX technical brochure (EN).pdf

PDF - 987.8kb -

Aflex Automotive Brochure (EN).pdf

PDF - 1.6mb

数据表

-

Hyperline FX Stainless steel braid (SS) grade hoses datasheet (ZH).pdf

PDF - 403.6kb -

Hyperline FX Tube only (TO) grade hoses datasheet (ZH).pdf

PDF - 304.3kb -

Hyperline FX Aramid fibre braid (AM) grade hoses datasheet (ZH).pdf

PDF - 389kb

其他资源

-

configure-for-abrasion.pdf

PDF - 232.1kb -

configure-for-bend.pdf

PDF - 164.2kb -

length-calculation.pdf

PDF - 192.4kb -

special-usage-conditions-hypx.pdf

PDF - 137.1kb

可选配件和附件

编织、包裹和外部保护

| 软管 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| 仅软管 - TO | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 不锈钢 - SS | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 橡胶盖 - RC | ✔ | ✔ | ✔ | ✔ | |||||

| 聚丙烯编织 - PB | ✔ | ✔ | |||||||

| 铂金硫化 - SI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 编织 | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| 塑料橡胶选件 | ✔ | ✔ | ✔ | ||||||

| Aramid | ✔ | ||||||||

| Kynar 编织 | ✔ | ||||||||

| 哈氏合金编织 | ✔ | ||||||||

| 蓝色 EPDM | ✔ | ✔ | ✔ | ||||||

| 黑色 EPDM | ✔ | ✔ | ✔ | ||||||

| 外部保护 | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| 保护套 - SG | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 磨损环 - SR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 保护圈 - PC | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 双橡胶盖端保护 - RC300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 双橡胶盖端保护 - DBK300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

端接头

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

|---|---|---|---|---|---|---|---|---|---|

| 转节法兰接头 - 非内衬 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 转节法兰接头 - 内衬 | ✔ | ✔ | ✔ | ✔ | |||||

| 外螺纹非内衬快装接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 外螺纹内衬快装接头 | ✔ | ✔ | ✔ | ✔ | |||||

| 内螺纹非内衬快装接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 内螺纹内衬快装接头 | ✔ | ✔ | ✔ | ✔ | |||||

| 卫生级 Triclamp 接头 PTFE 内衬和展开 | ✔ | ✔ | ✔ | ||||||

| 卫生级 Triclamp 接头 - 非内衬 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 卫生级和微型卫生级 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| 卫生级 Triclamp 接头 - 90° 弯管接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| DIN 11851 / SMS 接头 - PTFE 内衬 | ✔ | ✔ | ✔ | ||||||

| DIN 11851 接头 - 非内衬 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| RJT 内螺纹接头 - 非内衬 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| BSP 和 NPT 螺纹接头 - NPT 和 BSPT 接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| BSP 和 NPT 螺纹接头 - BSP 60° 锥形阀座内螺纹接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| JIC 接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| PTFE 水封管接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 3-A 卫生级接头 | ✔ | ✔ | ✔ | ✔ | |||||

| 90° 弯管接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 槽形立柱接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| IDF 内螺纹/外螺纹 - 非内衬 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| ENCAP 接头 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| PTFE 尾部或液压接头 | ✔ | ✔ | ✔ | ||||||

| PTFE 尾部接头 | ✔ | ✔ | ✔ | ✔ |