Bioprene hose

Bioprene hose elements. Meets FDA standards, resistant to alcohols, acids and oxidising products.

Hose pump elements

Call +44 1326 370 370

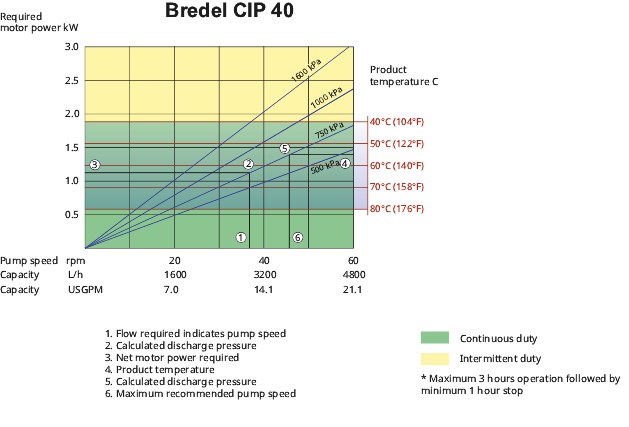

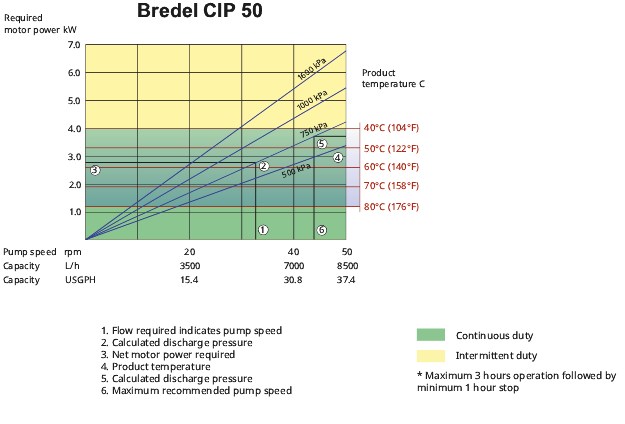

The Bredel CIP 40 and CIP 50 pumps are designed for food manufacture and other processes that require regular clean in place, with all the advantages of low shear, hygienic pumping. Recommended for sanitary processes, or other applications requiring regular cleaning of the process lines.

| Max. flow rate continuous | 8760 L/h |

| Max. flow rate continuous | 2311 USGPH |

| Volume per revolution | 1.33 - 2.92 L |

| Max. continuous operating speed | 50 - 60 rpm |

| Max. operating pressure | 16 bar |

| Max. operating pressure | 232 psi |

| Min. starting torque | 320 - 620 N m |

| Min. starting torque | 2832 - 5,487 in.lbs |

| Weight | 175 - 265 kg |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| CIP 40 | CIP 50 | |

|---|---|---|

| Max. flow rate continuous | 4788 L/h | 8760 L/h |

| Max. flow rate continuous | 1263 USGPH | 2311 USGPH |

| Max. flow rate intermittent | 4788 L/h | 8760 L/h |

| Max. flow rate intermittent | 1263 USGPH | 2311 USGPH |

| Volume per revolution | 1.33 L | 2.92 L |

| Volume per revolution | 0.35 USG | 0.77 USG |

| Max. continuous operating speed | 60 rpm | 50 rpm |

| Max. intermittent operating speed | 60 rpm | 50 rpm |

| Max. operating pressure | 16 bar | 16 bar |

| Max. operating pressure | 232 psi | 232 psi |

| Max. suction capability | 9.5 mWC | 9.5 mWC |

| Max. suction capability | 374 inWC | 374 inWC |

| Suction capability (80% Flow rate) | 9 mWC | 8 mWC |

| Suction capability (80% Flow rate) | 354 inWC | 315 inWC |

| Operating temperature range | -20 °C to 45 °C | -20 °C to 45 °C |

| Operating temperature range | -4 °F to 113 °F | -4 °F to 113 °F |

| Fluid temperature range | -20 °C to 80 °C | -20 °C to 80 °C |

| Fluid temperature range | -4 °F to 176 °F | -4 °F to 176 °F |

| Min. starting torque | 320 N m | 620 N m |

| Min. starting torque | 2832 in.lbs | 5487 in.lbs |

| Weight | 175 kg | 265 kg |

| Weight | 386 lbs | 584 lbs |

| Pumphead weight | 139 kg | 195 kg |

| Pumphead weight | 306 lbs | 430 lbs |

| Hose lubricant required | 10 L | 20 L |

| Hose lubricant required | 2.6 USG | 5.3 USG |

| Port configurations | Down, Left, Right, Up | Down, Left, Right, Up |

| Compatible hose materials | CSM, EPDM, F-NBR, NBR, NR, NR-Metering, NR-Transfer | CSM, EPDM, F-NBR, NBR, NR, NR-Metering, NR-Transfer |

| Compatible tube materials | Bioprene | Bioprene |

| Flange assembly type | ANSI, DIN, JIS | ANSI, DIN, JIS |

| Sanitary connector options | DIN 11851, DIN 11864, IDF, RJT, SMS, Tri-clamp | DIN 11851, DIN 11864, IDF, RJT, SMS, Tri-clamp |

| Type | A | B | C | C | D | Ød | E | F | G | H | H1 | Jmax | K | L | L1 | L2 | M | N | O | Q | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel CIP 40 (mm) | 702 | 412 | 2.5 | 10 | 430 | 40 | 110 | 454 | 508 | 615 | 325 | 414 | 64 | * | 260 | 80 | 25 | 700 | 25 | 18 | 110 |

| Bredel CIP 40 (inches) | 27.6 | 16.2 | 0.1 | 0.4 | 16.9 | 1.57 | 4.3 | 17.9 | 20.0 | 24.2 | 12.8 | 16.3 | 2.5 | * | 10.2 | 3.1 | 1.0 | 27.6 | 1.0 | 0.7 | 4.3 |

| Type | A | B | C | C | D | Ød | E | F | G | H | H1 | Jmax | K | L | L1 | L2 | M | N | O | Q | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bredel CIP 50 (mm) | 835 | 475 | 3 | 10 | 554 | 50 | 123 | 444 | 496 | 760 | 400 | 433 | 78 | * | 325 | 100 | 25 | 870 | 25 | 18 | 125 |

| Bredel CIP 50 (inches) | 32.9 | 18.7 | 0.1 | 0.4 | 21.8 | 1.97 | 4.8 | 17.5 | 19.5 | 29.9 | 15.7 | 17.0 | 3.1 | * | 12.8 | 3.6 | 1.0 | 34.3 | 1.0 | 0.7 | 4.9 |

| Hose material | Bioprene (tube), CSM, EPDM, F-NBR, Natural rubber (NR), NBR, NBR for food, NR-Metering |

| Housing | Cast iron |

| Rotor assembly | Cast iron |

| Cover assembly | Cast iron |

| Brackets and fasteners | Stainless steel 316 |

| Support frame | Galvanised steel, Stainless steel 316 |

| Hose clamps | Stainless steel 316 |

| Seals | NBR |

Bioprene hose elements. Meets FDA standards, resistant to alcohols, acids and oxidising products.

Hose pump elements

F-NBR hose elements. Suitable for all food products including oils and greases. Meets FDA, EC, EHEDG and 3A standards.

Hose pump elements

NBR (Buna N) hose elements. Resistant to oils, greases, alkalis and detergents.

Hose pump elements

Flow rates to 6,200 L/h (27.3 USGPM) and pressures up to 8 bar (116 psi). Optimised for process uptime.

Pumps - hose pumps

Flow rates to 5,250 L/h (23.1 USGPM) and pressures up to 16 bar (232 psi). Paint-free electroplated pump housing.

Pumps - hose pumps

Flow rates to 17,520 L/h (4,623 USGPH) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

Flow rates to 108,000 L/h (475 GPM) and pressures up to 16 bar (232 psi). Eliminate ancillary equipment.

Pumps - hose pumps

To order a product or ask a question