- Case Study

Craft brewery Dr. Gab’s benefits from longer hose life with Aflex FaBLINE

PTFE hoses prove superior to conventional rubber hoses in lifetime and hygiene

PTFE hoses prove superior to conventional rubber hoses in lifetime and hygiene

Switzerland-based craft brewery Dr. Gab’s upgraded its production capabilities by adopting Aflex FaBLINE hoses for challenging transfer tasks.

FaBLINE, with its innovative PTFE liner and no adhesives, has given Dr. Gab’s a significant increase in operating time, reliability and process safety, compared to the rubber hoses previously used in the brewery, which is based in Puidoux (VD).

From starting with a home brewing kit given as a birthday gift, the modern brewery in Puidoux can produce 2.4 million litres of beer a year.

Impeccable hygiene and strict quality control over the entire production play a key role at one of the largest breweries in the French-speaking part of Switzerland. Particularly important are special hoses, indispensable for numerous transfer tasks in the brewing process and essential for a smooth and efficient operation.

But with the previously used rubber hoses, Dr. Gab’s experienced defective and burst hoses which resulted in excessive cleaning and loss of product.

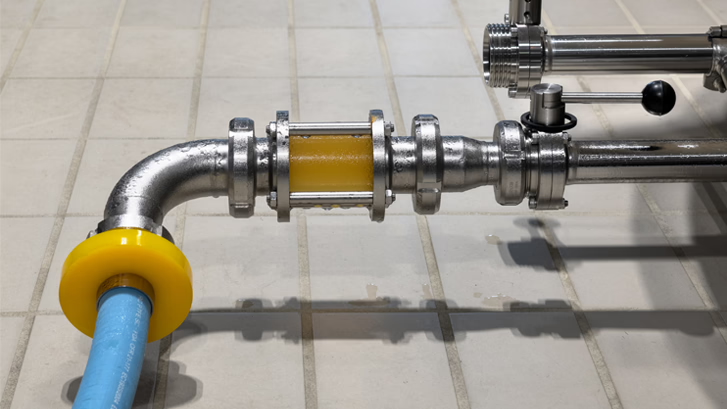

Therefore, Dr. Gab’s has increasingly relied on the new FaBLINE hoses from Aflex Hose for transferring the beer to and from the carbonator. Since purchasing over 25 FaBLINE hoses, Dr. Gab’s primarily uses them for challenging applications, such as final carbonation. After carbonic acid is added, the beer is transferred to the bottling line under high pressure. Here, the old hoses repeatedly failed.

Since switching to FaBLINE, Dr. Gab’s has seen a marked improvement in reliability. The PTFE hoses also provide significant cost advantages over conventional rubber hoses thanks to superiority in lifetime and hygiene.

Thanks to the patented PTFE liner design and reinforcement wire (316 SS), FaBLINE offers a significantly longer service life than rubber hoses.

Aflex FaBLINE offers further hygienic advantages. The fittings are made from one piece, are firmly crimped and offer a PTFE lined and flared design. The result is perfectly smooth surfaces without entrapment areas, and all wetted surfaces are PTFE-lined.

FaBLINE is also superior in handling, offering greater flexibility and at the same time being more kink-resistant, and has very good external protection with an anti-chafing spiral and protective scuff rings.

"With our previous rubber-lined hoses, we frequently encountered problems in challenging applications," said Reto Engler, Co-Founder and Production Director at Dr. Gab’s.

"Unlike the old rubber hoses, which usually only lasted a few months, there have been no problems with Aflex—no hose ruptures or burst hoses. On average, we had one rubber hose break per week, especially at the carbonator.We should concentrate on brewing beer and not repairing broken hoses.”

"Unlike the old rubber hoses, which usually only lasted a few months, there have been no problems with Aflex—no hose ruptures or burst hoses."

Due to FaBLINE’s longer hose life to the previously used rubber hoses, there is a reduced overall spend on hoses.

“All Aflex hoses feature a PTFE liner that is far superior to other materials such as rubber, silicone and PVC in comparable applications,” said Cedric Miotton, Sales Engineer at WMFTS. “PTFE offers unique non-stick properties, high chemical resistance and excellent temperature and pressure properties. It also does not absorb any product or cleaning chemicals.

"On FaBLINE hoses, the fittings are crimped, making a secure connection with the hose. Whereas with the previous rubber hoses, the fittings were screwed on by a clamp and could slip off the hose when pulled too hard.”

FaBLINE hoses also off these benefits for brewery companies:

Maximise the profitability of your food and beverage production with FaBLINE, the ultimate food...

Aflex

View our range of flexible PTFE-lined hoses from Aflex Hose

Case Study

Engineering experts at Aflex have developed FaBLINE to meet the latest hygiene standards.

Case Study

To order a product or ask a question call +44 1326 536 800 or