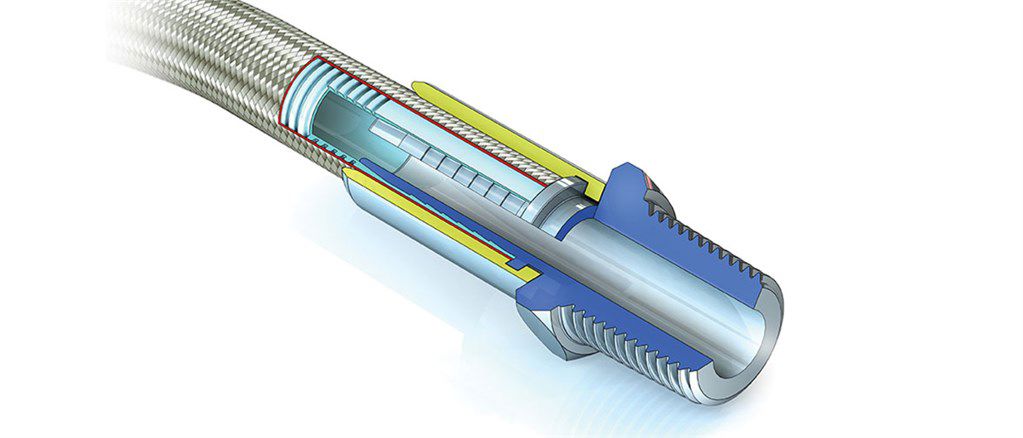

Smoothbore hose

Smooth bore hose for most automotive and general purpose applications. Usable at high pressures.

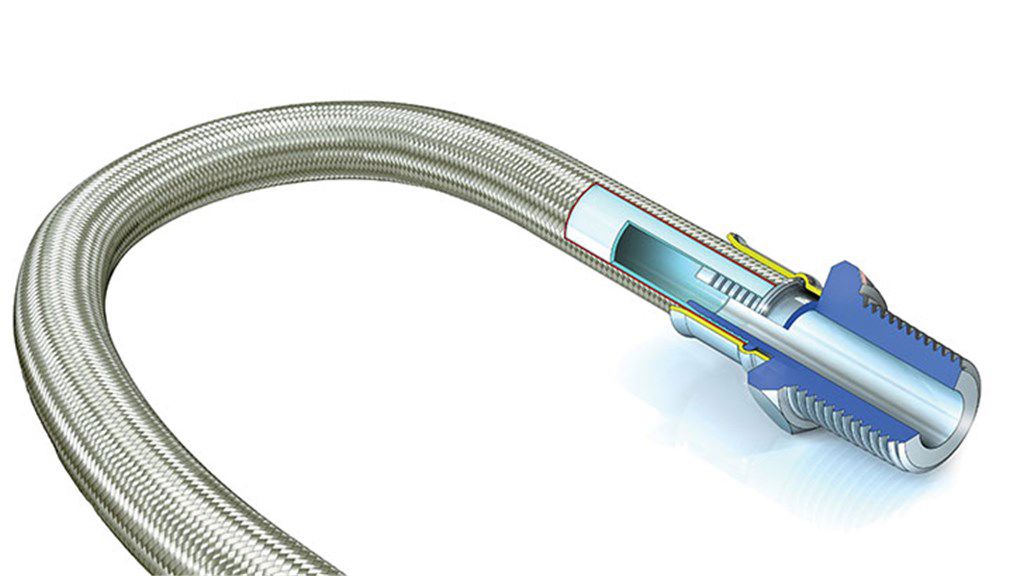

Flexible hose assemblies

PTFE-lined hose for automotive and general purpose applications

Hyperline FX hose is much more flexible than smoothbore hose, due to the patented design of the PTFE liner, and therefore represents a better alternative in applications where improved flexibility is required. Particularly applicable for the tight configurations increasingly necessary in automotive hose and aerospace hose applications, where space requirements are limited.

| Nominal bore size | 6 - 25 mm |

| Nominal bore size | 0.25 - 1 in |

| Outside diameter | 9 - 31.7 mm |

| Outside diameter | 0.354 - 1.25 in |

| Max. operating pressure | 88 bar |

| Max. operating pressure | 1280 psi |

| Certification and compliance | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1737, TS 16949:2016 |

| Bend radius | 19 - 150 mm |

| Bend radius | 0.75 - 6 in |

| Braid type | None |

| Cover | None |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| Hose Bore Size | Actual Hose Bore Size | Hose | Outside Diameter of Tube or Braid | Minimum Bend Radius | Maximum Working Pressure (MWP) | Burst Pressure | Weight per Unit Length | *Part Number | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | dash size | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.250 - 0.280 | 6.35 - 7.12 | AM | 0.360 - 0.400 | 9.14 - 10.16 | 1 1/2 | 38 | 77 | 1116 | 231 | 3350 | 0.056 | 0.038 | 92-100-04-01-55-01 |

| 5/16 | 5 | 0.290 - 0.320 | 7.36 - 8.13 | AM | 0.440 - 0.480 | 11.17 - 12.19 | 1 1/2 | 38 | 74 | 1073 | 222 | 3220 | 0.075 | 0.050 | 92-100-05-01-55-01 |

| 3/8 | 6 | 0.376 - 0.406 | 9.55 - 10.32 | AM | 0.515 - 0.555 | 13.08 - 14.10 | 2 | 50 | 70 | 1015 | 210 | 3046 | 0.100 | 0.094 | 92-100-06-01-55-01 |

| 1/2 | 8 | 0.515 - 0.545 | 13.08 - 13.85 | AM | 0.655 - 0.695 | 16.64 - 17.66 | 3 | 76 | 52 | 754 | 156 | 2263 | 0.140 | 0.094 | 92-100-08-01-55-01 |

| 5/8 | 10 | 0.635 - 0.665 | 16.13 - 16.89 | AM | 0.815 - 0.855 | 20.70 - 21.72 | 4 | 100 | 44 | 638 | 132 | 1915 | 0.204 | 0.137 | 92-100-10-01-55-01 |

| 3/4 | 12 | 0.760 - 0.790 | 19.30 - 20.07 | AM | 0.946 - 0.986 | 24.03 - 25.05 | 5 | 126 | 36 | 522 | 108 | 1566 | 0.236 | 0.158 | 92-100-12-01-55-01 |

| 1 | 16 | 1.005 - 1.035 | 25.52 - 26.29 | AM | 1.233 - 1.273 | 31.32 - 32.34 | 6 | 150 | 35 | 507 | 105 | 1523 | 0.354 | 0.237 | 92-100-16-01-55-01 |

*For anti-static grade, add 10 to the 3-digit part number e.g. 92-100- becomes 92-110.

The performance testing results stated in the above table have been carried out at ambient temperature, in a controlled laboratory environment, using water as the media. We recommend that the customer carries out stringent application performance testing on the hose, using the actual working conditions over a set period of time to validate the hose.

| Hose Bore Size | Actual Hose Bore Size | Hose | Outside Diameter of Tube or Braid | Minimum Bend Radius | Maximum Working Pressure (MWP) | Burst Pressure | Weight per Unit Length | *Part Number | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | dash size | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.250 - 0.280 | 6.34 - 7.12 | SS | 0.355 - 0.395 | 9.02 - 10.04 | 3/4 | 19 | 110 | 1595 | 330 | 4786 | 0.092 | 0.062 | 92-100-04-01-02 |

| 5/16 | 5 | 0.302 - 0.328 | 7.66 - 8.33 | SS | 0.424 - 0.458 | 10.77 - 11.63 | 3/4 | 19 | 105 | 1522 | 315 | 4569 | 0.126 | 0.084 | 92-100-05-01-02 |

| 3/8 | 6 | 0.376 - 0.406 | 9.54 - 10.32 | SS | 0.502 - 0.542 | 12.75 - 13.64 | 1 | 25 | 100 | 1450 | 300 | 4351 | 0.160 | 0.151 | 92-100-06-01-02 |

| 1/2 | 8 | 0.515 - 0.545 | 13.07 - 13.85 | SS | 0.655 - 0.695 | 16.64 - 17.66 | 1 1/2 | 38 | 75 | 1087 | 225 | 3263 | 0.225 | 0.151 | 92-100-08-01-02 |

| 5/8 | 10 | 0.635 - 0.665 | 16.12 - 16.89 | SS | 0.810 - 0.850 | 20.57 - 21.59 | 2 | 50 | 62 | 899 | 186 | 2698 | 0.336 | 0.226 | 92-100-10-01-02 |

| 3/4 | 12 | 0.760 - 0.790 | 19.30 - 20.07 | SS | 0.950 - 0.990 | 24.13 - 25.15 | 2 1/2 | 63 | 52 | 754 | 156 | 2263 | 0.383 | 0.257 | 92-100-12-01-02 |

| 1 | 16 | 1.005 - 1.035 | 25.52 - 26.29 | SS | 1.227 - 1.269 | 31.15 - 32.23 | 3 | 75 | 50 | 725 | 150 | 2176 | 0.540 | 0.362 | 92-100-16-01-02 |

*For anti-static grade, add 10 to the 3-digit part number e.g. 92-100- becomes 92-110.

The performance testing results stated in the above table have been carried out at ambient temperature, in a controlled laboratory environment, using water as the media. We recommend that the customer carries out stringent application performance testing on the hose, using the actual working conditions over a set period of time to validate the hose.

| Hose Bore Size | Actual Hose Bore Size | Hose | Outside Diameter of Tube or Braid | Minimum Bend Radius | Maximum Working Pressure (MWP) | Burst Pressure | Weight per Unit Length | *Part Number | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | dash size | in | mm | in | mm | in | mm | Bar | Psi | Bar | Psi | Kg/mtr | Lbs/Ft | * | |

| 1/4 | 4 | 0.252 - 0.278 | 6.39 - 7.06 | TO | 0.326 - 0.368 | 8.28 - 9.35 | 1 1/2 | 38 | 6 | 87 | 18 | 261 | 0.041 | 0.027 | 92-100-04 |

| 5/16 | 5 | 0.308 - 0.333 | 7.84 - 8.46 | TO | 0.382 - 0.424 | 9.72 - 10.77 | 1 1/2 | 38 | 6 | 87 | 18 | 261 | 0.056 | 0.037 | 92-100-05 |

| 3/8 | 6 | 0.381 - 0.407 | 9.69 - 10.34 | TO | 0.475 - 0.511 | 12.06 - 12.98 | 2 | 50 | 6 | 87 | 18 | 261 | 0.070 | 0.047 | 92-100-06 |

| 1/2 | 8 | 0.525 - 0.550 | 13.33 - 13.97 | TO | 0.620 - 0.668 | 15.77 - 16.97 | 3 | 76 | 6 | 87 | 18 | 261 | 0.110 | 0.074 | 92-100-08 |

| 5/8 | 10 | 0.639 - 0.665 | 16.25 - 16.89 | TO | 0.770 - 0.811 | 19.55 - 20.60 | 4 | 100 | 6 | 87 | 18 | 261 | 0.161 | 0.108 | 92-100-10 |

| 3/4 | 12 | 0.765 - 0.795 | 19.42 - 20.20 | TO | 0.895 - 0.941 | 22.73 - 23.90 | 5 | 126 | 6 | 87 | 18 | 261 | 0.179 | 0.120 | 92-100-12 |

| 1 | 16 | 1.005 - 1.035 | 25.77 - 26.55 | TO | 1.165 - 1.215 | 29.58 - 30.86 | 6 | 150 | 6 | 87 | 18 | 261 | 0.268 | 0.180 | 92-100-16 |

*For anti-static grade, add 10 to the 3-digit part number e.g. 92-100- becomes 92-110.

The performance testing results stated in the above table have been carried out at ambient temperature, in a controlled laboratory environment, using water as the media. We recommend that the customer carries out stringent application performance testing on the hose, using the actual working conditions over a set period of time to validate the hose.

| Hyperline FX Aramid fibre braid (AM) grade hoses | Hyperline FX Stainless steel braid (SS) grade hoses | Hyperline FX Tube only (TO) grade hoses | |

| Nominal bore size | 6 - 25 mm (0.25 - 1 in) | 6 - 25 mm (0.25 - 1 in) | 6 - 25 mm (0.25 - 1 in) |

| Actual bore size | 6.8 - 26 mm (0.27 - 1.023 in) | 6.8 - 26 mm (0.27 - 1.023 in) | 6.8 - 26 mm (0.27 - 1.023 in) |

| Length | 18 m (60 Ft) | 18 m (60 Ft) | 18 m (60 Ft) |

| Outside diameter | 9.6 - 31.7 mm (0.378 - 1.25 in) | 9.6 - 31.7 mm (0.378 - 1.25 in) | 9 - 30.3 mm (0.354 - 1.193 in) |

| Max. operating pressure | 62 bar (900 psi) | 88 bar (1280 psi) | 4 bar (60 psi) |

| Burst pressure | 84 - 186 bar (1200 - 2,700 psi) | 120 - 264 bar (1740 - 3,840 psi) | 6 - 12 bar (87 - 180 psi) |

| Certification and compliance | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1737, TS 16949:2016 | 3.1 Traceability, EN16643:2016, FDA (materials), SAE J1737, TS 16949:2016 |

| Operating temperature | -40 °C to 180 °C (-40 °F to 356 °F) | -73 °C to 260 °C (-100 °F to 500 °F) | -73 °C to 260 °C (-100 °F to 500 °F) |

| Bend radius | 38 - 150 mm (1.5 - 6 in) | 19 - 75 mm (0.75 - 3 in) | 38 - 150 mm (1.5 - 6 in) |

| Weight per unit length | 0.056 - 0.354 kg/m (0.038 - 0.237 lb/ft) | 0.092 - 0.54 kg/m (0.062 - 0.362 lb/ft) | 0.041 - 0.268 kg/m (0.027 - 0.18 lb/ft) |

| Braid type | None | ||

| Cover | None | None | None |

| End fitting | BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, ENCAP end fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, Swivel flange fittings | BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, ENCAP end fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, Swivel flange fittings | BSP and NPT threaded fittings, CAM and groove fittings, DIN 11851 fittings, ENCAP end fittings, JIC fittings, PTFE dip pipe fittings, Sanitary triclamp fittings, Swivel flange fittings |

| Vacuum resistance | Vacuum resistant to -0.9 bar up to 150 °C (302 °F) |

| Liner tube | Anti-static PTFE, Natural PTFE |

| Braid | Aramid fibre, Stainless steel |

| Hose | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Tube only -TO | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Stainless Steel - SS | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Rubber Covered - RC | ✔ | ✔ | ✔ | ✔ | |||||

| Polypropylene Braid - PB | ✔ | ✔ | |||||||

| Platinum Cured - SI | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Braids | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Plastic Rubber option | ✔ | ✔ | ✔ | ||||||

| Aramid | ✔ | ||||||||

| Kynar Braid | ✔ | ||||||||

| Hastelloy Braid | ✔ | ||||||||

| Blue EPDM | ✔ | ✔ | ✔ | ||||||

| Black EPDM | ✔ | ✔ | ✔ | ||||||

| External protections | |||||||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

| Safeguard Protection Sleeve - SG | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Scuff Ring - SR | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Protection Coil - PC | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Double Rubber Cover End Protection - RC300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Double Rubber Cover End Protection - DBK300 | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Bioflex Ultra | Pharmaline N | Pharmaline X | FaBLINE | Corroflon | Corroline+ | Smoothbore | Hyperline FX | Visiflon | |

|---|---|---|---|---|---|---|---|---|---|

| Swivel Flange Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Swivel Flange Fittings - Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Male Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Male Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Cam & Groove Fittings Female Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Cam & Groove Fittings Female Lined | ✔ | ✔ | ✔ | ✔ | |||||

| Sanitary Triclamp Fittings PTFE Lined and Flared | ✔ | ✔ | ✔ | ||||||

| Sanitary Triclamp Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary & Mini Sanitary | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| Sanitary Triclamp Fittings - 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| DIN 11851 / SMS Fittings - PTFE Lined | ✔ | ✔ | ✔ | ||||||

| DIN 11851 Fittings - Non-Lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| RJT Female Fittings - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||

| BSP & NPT Threaded Fittings - NPT & BSPT Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| BSP & NPT Threaded Fitting - BSP 60° Cone seat female fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| JIC Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| PTFE Dip Pipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| 3-A Sanitary Fittings | ✔ | ✔ | ✔ | ✔ | |||||

| 90° Elbow Fitting | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Grooved Standpipe Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| IDF Female / Male - Non-lined | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| ENCAP Fittings | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| PTFE Tail or Hydraulic Fittings | ✔ | ✔ | ✔ | ||||||

| PTFE Tail Fittings | ✔ | ✔ | ✔ | ✔ |

Smooth bore hose for most automotive and general purpose applications. Usable at high pressures.

Flexible hose assemblies

Convoluted bore hose for all applications where a smooth bore and/or high pressures are not required.

Flexible hose assemblies

To order a product or ask a question