- Food and beverage

The hose is the key

The precision manufactured hose is the single most vital component for the performance, durability, and efficiency of the hose pump. To ensure perfect compression and consistent, reliable performance, Bredel manufactures hoses from high quality compounded rubbers, reinforced with four individual layers of braided nylon. Perfect compression eliminates slip which, in other pumps, can destroy shear sensitive product, reduce metering accuracy, or allow abrasive slurries to wreak havoc on wet parts. Bredel engineers hoses to meet the flow, pressure and temperature characteristics of your toughest applications.

Hose construction

The essential component of high-performance hose pumps is a hose that is constructed of layers of rubber reinforced by winding several layers of nylon cords. The inner layer is available in a range of rubber compounds.

Designed to perfection

Bredel is on the cutting edge of technology to engineer, manufacture and test our pumps.

Innovation

As the global leader in hose pumps, we pride ourselves on new ideas and innovative products that bring the benefits of hose pumps to our customers in an ever expanding range of applications. For example, retractable pressing shoes bring ultimate clean-in-place capability.

Design

Using tools like finite element analysis (FEA), we design our hoses to perfection – right down to the position of the reinforcing layers, angles and thickness of the cord reinforcement, and the thickness of the rubber. Everything from the geometry of the pressing shoe to the pump housing is engineered to optimise the performance of the hose.

Production

Unique in the world, Bredel’s state-of-the-art automated hose grinding facility machines every hose within fine tolerances – guaranteeing proper compression for efficiency and longevity. At our ISO9001:2000 factory, each pump and hose is constructed to the most rigorous quality controls standards.

Precision hose ensure

- Tight tolerances for low stress on bearings

- Perfect compression for long life

- Consistent capacity independent of varying suction and discharge conditions

Products

-

![Natural rubber (NR) Metering hose]()

Natural rubber (NR) Metering hose

Natural Rubber hose elements. Outstanding abrasion resistance. Generally resistant to diluted acids and alcohols.

Hose pump elements

-

![Natural rubber (NR) Transfer hose]()

Natural rubber (NR) Transfer hose

Natural Rubber hose elements. Outstanding abrasion resistance. Generally resistant to diluted acids and alcohols.

Hose pump elements

-

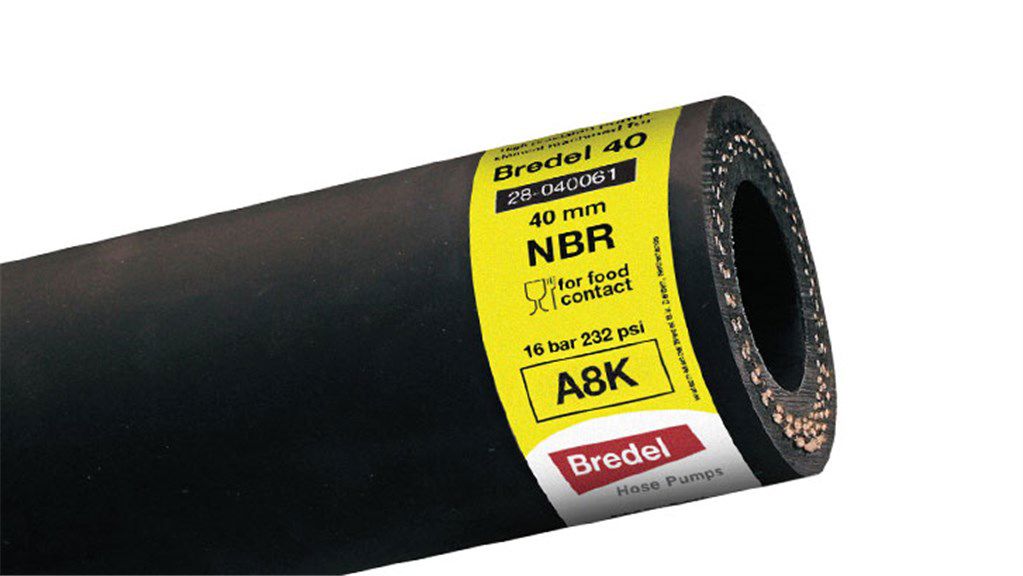

![NBR for food hose]()

NBR for food hose

NBR for Food hose elements. Suitable for a wide range of food products. Resistant to most cleaning chemicals.

Hose pump elements

-

![F-NBR hose]()

F-NBR hose

F-NBR hose elements. Suitable for all food products including oils and greases. Meets FDA, EC, EHEDG and 3A standards.

Hose pump elements

-

![Bioprene hose]()

Bioprene hose

Bioprene hose elements. Meets FDA standards, resistant to alcohols, acids and oxidising products.

Hose pump elements

-

![APEX NBR for food hose]()

APEX NBR for food hose

NBR for Food hose element for APEX hose pumps. Suitable for a wide range of food products including fatty foodstuff. Compliant to EC1935/2004

Hose pump elements

-

![APEX F-NBR hose]()

APEX F-NBR hose

F-NBR hose element for APEX hose pumps. Suitable for a wide range of food products including dairy. Compliant to EC1935/2004 and FDACFR177.2600

Hose pump elements

Contact a specialist from the Bredel team

To order a product or ask a question call +64 9 273 3166 or