- Insight

How WMArchitect™ Interchangeable Parts service strengthens single-use systems and avoids supply chain disruptions

Expert Q&A

Expert Q&A

Single-use systems have transformed biopharmaceutical manufacturing, offering flexibility and speed in delivering life-saving medicines to patients. However, the COVID-19 pandemic exposed significant vulnerabilities in the supply chain, creating challenges for manufacturers and suppliers across the value chain. To address these issues, the industry needed an innovative approach to maintain resilience and ensure uninterrupted production.

Watson-Marlow Fluid Technology Solutions launched WMArchitect™ Interchangeable Parts service in 2025 to provide greater supply agility for single-use assemblies. Interchangeable Parts incorporates pre-qualified, alternative components in the design stage of your single-use assembly.

In this expert Q+A, Dr. Nicole Hunter, Head of Global WMArchitect™ single-use solutions, outlines how biopharmaceutical manufacturers and suppliers can take steps to secure a resilient supply of single-use assemblies by including pre-qualified, alternative components in the design stage to avoid regulatory compliance interruptions and long lead times.

During the COVID-19 pandemic, demand for single-use technology surged, and lead times for critical components became painfully long. The entire biopharma supply chain struggled to keep pace. As an industry, we realised we weren’t resilient enough to handle sudden shifts in demand.

Another challenge was that when a single component in an assembly is validated, any delay in its delivery can stall the entire process. This often leads to production stoppages and delays that ultimately impact patients waiting for therapies. If you can’t get a component, you can’t build the assemblies. Because of the threat of delays for biomanufacturers, there was a lot of overordering and stockpiling, which just exacerbated the supply situation.

Our goal was clear: minimise the risk of production downtime when a component faces long lead times or becomes unavailable.

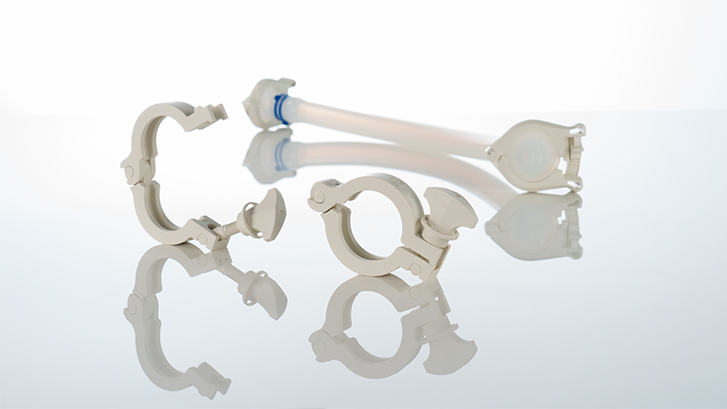

We introduced the WMArchitect™ Interchangeable Parts, designed to strengthen supply chain resilience and avoid production stoppages when a component either has a long lead time or becomes unavailable. By incorporating pre-qualified alternative components during the design stage, we help customers avoid regulatory compliance interruptions and reduce the risk of delays for critical items such as tubing, tri-clamps, and other fittings. Interchangeable Parts helps eliminate disruptions caused by limited component availability and the risk of production shutdowns. Instead, it provides a streamlined approach to substituting suitable components with shorter lead times.

To ensure compatibility, performance, and safety, we adopted BioPhorum’s best practice equivalency assessment method in our Interchangeable Parts service to address any concerns over compatibility, performance and safety. This approach maintains full compliance and traceability while enabling quick substitution of components with shorter lead times, which keeps workflows on track.

“To ensure compatibility, performance, and safety, we adopted BioPhorum’s best practice equivalency assessment method in our Interchangeable Parts service to address any concerns over compatibility, performance and safety.”

As a long-standing BioPhorum member, we were actively discussing how to prepare for future emergencies. It became clear that validating only one component in a process was a major constraint.

The concept of interchangeable parts gained strong support, leading to the development of the BioPhorum interchangeability assessment and qualification best practice guide. One of the biggest hurdles was uncertainty around validation requirements and regulatory perspectives. Through collaboration, we explored how to classify changes (whether they were like-for-like, functionally equivalent, or functional modifications) ensuring clarity for manufacturers and regulators alike.

Our Interchangeable Parts service removes the risk of disruptions caused by limited component availability and potential production shutdowns, offering a straightforward way to substitute suitable components with shorter lead times.

It incorporates pre-qualified alternative components into the assembly design, agreed upon during the initial stage. This proactive approach helps prevent supply constraints for critical parts such as tubing, tri-clamps, and other fittings.

At the design enquiry stage we would consult and look at component availability and agree if there are any opportunities for interchangeability. It might be multiple components in an assembly, it might be just one. Then when an order is placed we check if all of those components are easily available. Everything is done up front.

We continuously monitor component lead times to identify gradual or sudden changes. If a component is flagged, we can quickly pivot to a pre-approved alternative with a shorter lead time, whether sourced from WMFTS or a trusted third party. This ensures maximum versatility.

To future-proof supply, the service adds flexibility and versatility to processes, ensuring efficient change management and providing regulators with greater confidence in continuity and compliance.

Our vision is to expand the WMArchitect™ Interchangeable Parts service to cover a broader range of components. BioPhorum will continue to play a central role in aligning industry practices and embedding interchangeability as a standard approach, which future proofs supply chains for years to come.

News

Watson-Marlow Fluid Technology Solutions launches WMArchitect™ Interchangeable Parts to provide...

News/Insight

Your partner for fluid path excellence in the Pharmaceutical and Biotechnology sector

To order a product or ask a question call +91 97640 99666 or