In beer production, damaged yeast can lead to wasted product, lost time and increased costs. To avoid these problems, St Austell Brewery has depended on the reliable and shear-sensitive peristaltic pumps from Watson-Marlow Fluid Technology Solutions (WMFTS) for over a decade.

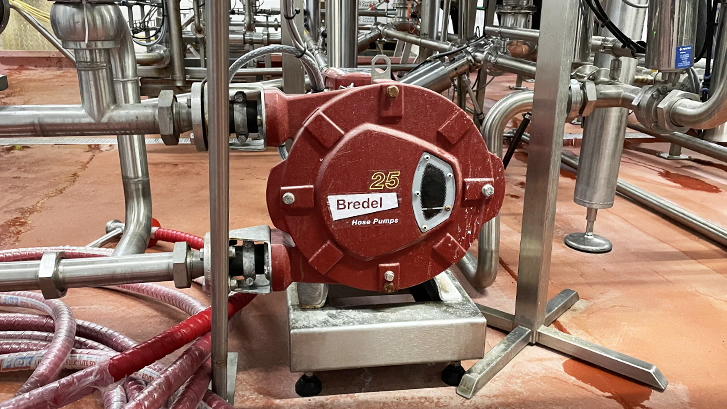

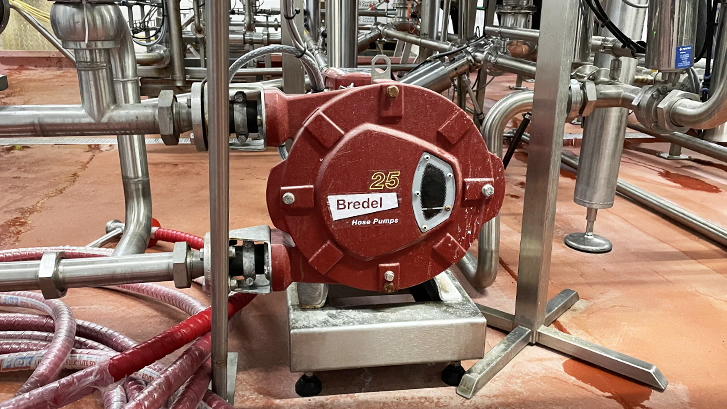

St Austell Brewery, which produces award-winning pale ale Tribute and korev lager among other beers, uses three types of Bredel hose pumps in its production:

• Bredel 15: for yeast dosing and recirculation, and handling beer slurry in the bottling hall

• Bredel 25: for daily yeast dosing during production

• Bredel 50: for transferring beer to cask filling heads

Yeast, a delicate organism crucial to the brewing process, can be easily damaged by aggressive pumping methods, which leads to waste products, rising costs and increased production times.

St Austell Brewery has prevented disruptions and additional costs from damaged yeast by relying on Bredel hose pumps for dosing, transferring or harvesting shear-sensitive yeast and circulating beer, due to their gentle, low shear pumping action which preserves yeast integrity. This maintains a high quality of beer, reduces yeast costs, and minimises the generation of waste sludge.

The accuracy of the pumps and performance in handling various viscosities are also important as under or overdosing of yeast would result in slow or incomplete fermentation, and an inconsistent beer. Recovering yeast (or yeast harvesting) following fermentation requires a pump which can handle thicker viscosities. Bredel hose pumps deliver a fixed volume of liquid every revolution, dosing the required amount irrespective of fluid viscosity or process conditions, without shear and without oxygen being introduced.

Hugely reliable pumps

St Austell Brewery also uses a Watson-Marlow 630UN at its historic brewery in Cornwall to dose peracetic acid during Clean-in-Place (CIP) sterilisation of vessels and process pipework. The 630 pump is chosen for its robust chemical resistance, containment of a harmful chemical and dosing accuracy, which helps minimise chemical costs. The 630 pump is also backed up by a five-year warranty.

Lee Walker, St Austell Group Engineering Development Manager, said: “Most importantly the pumps are low shear. We want healthy yeast going into our beers and the gentle handling of the Bredel pumps makes sure this is the case.

“Most importantly the pumps are low shear. We want healthy yeast going into our beers and the gentle handling of the Bredel pumps makes sure this is the case. It’s also important the pumps are sanitary, if they weren’t it could ruin a batch of beer. The correct dosing of peracetic acid with the Watson-Marlow 630 is very important for cleaning applications, so it just doses the amount we need to keep chemical costs to a minimum.

Lee Walker, St Austell Group Engineering Development Manager

“We can trust the Bredel pumps to handle yeast carefully. Damaged or roughly pumped yeast would result in increased costs, time lost, product waste, filtration issues, low yeast viability, and incomplete bottle conditioning.

“It’s also important the pumps are sanitary, if they weren’t it could ruin a batch of beer. The correct dosing of peracetic acid with the Watson-Marlow 630 is very important for cleaning applications, so it just doses the amount we need to keep chemical costs to a minimum.

“We like it that the pumps are also self-priming, there is an easy change of pump element, and they rarely fail. Maintenance is really easy, simple to change the hoses and really reliable. We have found the Bredel and Watson-Marlow pumps hugely reliable, one of the most reliable pieces of our plant.”

St Austell Brewery's long-standing partnership with WMFTS highlights the reliability and efficiency of Bredel hose pumps and Watson-Marlow cased pumps. By selecting the right pump for each specific application, the award-winning brewery has optimised its operations and maintained its commitment to producing high-quality beer.

St Austell Brewery values Bredel hose pumps for their:

- Ability to handle viscous fluids

- Gentle, low shear pumping action

- High accuracy

- High suction capability

- Minimal, easy and low-cost maintenance

- Hygienic, CIP capability

Learn more about Bredel hose pump

Learn more about Watson-Marlow 600 series cased pump