How do rotary lobe pumps work?

Rotary lobe pumps are a high-value positive displacement pump technology used widely across the pharmaceutical, food and beverage industries.

Call +61 2 8787 1400

Rotary lobe pumps are a high-value positive displacement pump technology used widely across the pharmaceutical, food and beverage industries.

Rotary lobe pumps are a type of positive displacement pump technology used widely across the pharmaceutical, industrial, hygienic and food and beverage industries. The pumps are typically constructed from stainless steel materials which gives them sanitary qualities, including clean-in-place (CIP) and steam-in-place (SIP) capabilities.

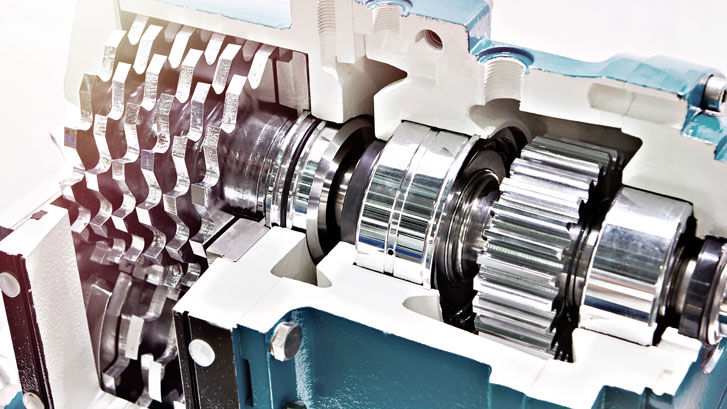

Lobe pumps make use of one or more lobes that rotate around parallel shafts to trap a volume of fluid into a chamber. Driven by timing gears, lobes rotate independently to create a vacuum on the priming side of the pump, which draws the product into the pump chamber and into the pressure area. Flow moves from the pump’s inlet port around the outside of the lobes to the outlet port. The product is forced out through the outlet port by continuous pumping.

Updated

Low shear, zero pulsation and self-draining pump certified with EHEDG Type EL Class I and EHEDG Type EL Aseptic Class I.

Pumps - sine pumps

Updated

Flow rates to 3.5 L/min (55 USGPH) and pressures up to 7 bar (100 psi). Precise 2,200:1 speed control range.

Pumps - cased pumps

In food and beverage, cosmetic and hygienic applications, Certa Sine pumps are a popular technology choice able to handle wide range of viscosities without performance loss. Designed to deliver lower shear and virtually no pulsation, Certa Sine pumps offer the optimum combination of gentle handling, high suction capability and superior energy efficiency to optimise a process.

Mee (MasoSine energy efficiency) curves demonstrate that sine pump technology delivers significant energy saving benefits for users in hygienic applications.

South African Breweries (SAB), a major brewery and subsidiary of Anheuser-Busch InBev SA/NV, has introduced three Certa Sine 400 pumps to use as part of a yeast cropping application. SAB made the purchase decision after assessing energy consumption comparisons between Certa Sine pumps and comparable lobe or circumferential piston pumps.

Efficiency - uses up to 50% less power than alternative pump technologies:

Certa Sine pumps provide lower energy costs for high viscosity applications, from frozen orange juice to cheese curd, to reduce electricity costs and carbon emissions.

Lower total cost of ownership:

One shaft, one rotor, one seal and no timing gears.

Handles viscosity:

Best NIPR/NPSHR in the market to reduce risk of cavitation.

Prevents aeration and foaming:

Certa Sine pumps have eliminated gas locking and boosted pump efficiency in yeast handling after they replaced rotary lobe pumps at Germany-based Hofmann brewery.

Smaller footprint:

The space-saving Certa Compact model of the Certa Sine pump range has a 30% footprint reduction compared to the existing Certa Sine pump range and competitive technologies.

Reliably hygienic and energy efficient. Certa pumps offer EHEDG (Type EL Class I and EL Aseptic Class I) and 3A certification as standard.