EPDM gaskets

Achieves a smooth bore, contamination free fluid path under clamping compression. Superior Steam-in-Place (SIP) stability.

Fluid path - gaskets

Call +61 2 8787 1400

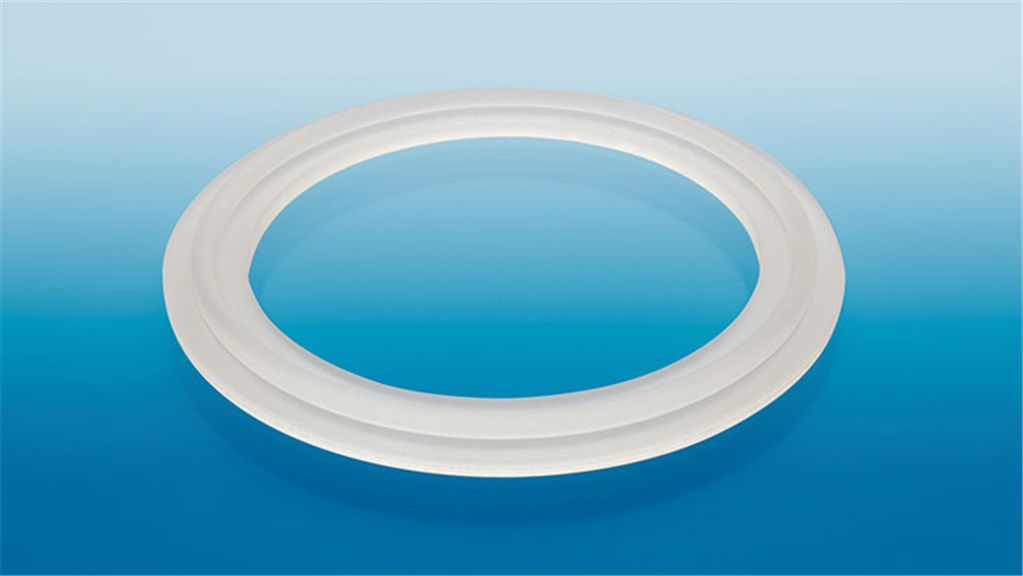

Manufactured and packed within an ISO 14644-1 Class 7 cleanroom, these high purity silicone gaskets are ideally suited for bioprocessing fluid paths. Demonstrating comprehensive knowledge of the materials involved in packaging components, the 5000 series gaskets have a low extractable profile. They are also gamma stable for irradiation up to 50 kGY, and autoclavable.

Product validation performed on post gamma-irradiated gaskets.

Extractable studies have been performed using a multi-solvent approach to BPOG guidelines.

| Gasket type | Unflanged |

| Certification and compliance | ADCF, ISO 10993, ISO Class 7, Ph. Eur. 3.1.9, USP <788>, USP <95>, USP <97>, USP Class VI |

| Shelf life | 5 years |

| Gamma stability | Max 50 kGy |

Technical Summary table lists features available within the range. See ‘Specifications’ tab for model specific information.

| Small Silicone 5000 Gaskets | Standard Silicone 5000 Gaskets | |

|---|---|---|

| Gasket type | Unflanged | Unflanged |

| Internal diameter | 10.9 - 16 mm | 22.9 - 147.8 mm |

| Internal diameter | 0.43 - 0.63 in | 0.9 - 5.82 in |

| External diameter | 21.6 mm | 50.3 - 165.4 mm |

| External diameter | 0.85 in | 1.98 - 6.51 in |

| Size | 0.5, 0.75 in | 1, 1.5, 2, 2.5, 3, 4, 6 in |

| Quantity | 25 PCS | 25 PCS |

| Certification and compliance | ADCF, ISO 10993, ISO Class 7, Ph. Eur. 3.1.9, USP <788>, USP <95>, USP <97>, USP Class VI | ADCF, ISO 10993, ISO Class 7, Ph. Eur. 3.1.9, USP <788>, USP <95>, USP <97>, USP Class VI |

| Operating temperature range | -55 °C to 210 °C | -55 °C to 210 °C |

| Operating temperature range | -67 °F to 410 °F | -67 °F to 410 °F |

| Shelf life | 5 years | 5 years |

| Gamma stability | Max 50 kGy | Max 50 kGy |

| Material | Platinum-cured silicone |

| BioPure High Purity Platinum-Cured Silicone Gasket—Laser Etched | ||||

|---|---|---|---|---|

| Part number | Size inch | O.D inch (A) | I.D inch (B) | Quantity |

| 5001.0050.025 | 1/2 | 0.85 (21.6) | 0.43 (10.9) | 25 |

| 5001.0075.025 | 3/4 | 0.85 (21.6) | 0.63 (16.0) | 25 |

| BioPure High Purity Platinum-Cured Silicone Gasket | ||||

|---|---|---|---|---|

| Part number | Size inch | O.D inch (A) | I.D inch (B) | Quantity |

| 5201.0050.025 | 1/2 | 0.85 (21.6) | 0.43 (10.9) | 25 |

| 5201.0075.025 | 3/4 | 0.85 (21.6) | 0.63 (16.0) | 25 |

| BioPure High Purity Platinum-Cured Silicone Gasket—Laser Etched | ||||

|---|---|---|---|---|

| Part number | Size inch | O.D inch (A) | I.D inch (B) | Quantity |

| 5001.0100.025 | 1 | 1.98 (50.3) | 0.90 (22.9) | 25 |

| 5001.0150.025 | 1 1/2 | 1.98 (50.3) | 1.40 (35.6) | 25 |

| 5001.0200.025 | 2 | 2.52 (64.0) | 1.90 (48.3) | 25 |

| 5001.0250.025 | 2 1/2 | 3.05 (77.5) | 2.40 (61.0) | 25 |

| 5001.0300.025 | 3 | 3.58 (90.9) | 2.90 (73.7) | 25 |

| 5001.0400.025 | 4 | 4.68 (118.9) | 3.87 (98.3) | 25 |

| 5001.0600.025 | 6 | 6.51 (165.4) | 5.82 (147.8) | 25 |

| BioPure High Purity Platinum-Cured Silicone Gasket | ||||

|---|---|---|---|---|

| Part number | Size inch | O.D inch (A) | I.D inch (B) | Quantity |

| 5201.0100.025 | 1 | 1.98 (50.3) | 0.90 (22.9) | 25 |

| 5201.0150.025 | 1 1/2 | 1.98 (50.3) | 1.40 (35.6) | 25 |

| 5201.0200.025 | 2 | 2.52 (64.0) | 1.90 (48.3) | 25 |

| 5201.0250.025 | 2 1/2 | 3.05 (77.5) | 2.40 (61.0) | 25 |

| 5201.0300.025 | 3 | 3.58 (90.9) | 2.90 (73.7) | 25 |

| 5201.0400.025 | 4 | 4.68 (118.9) | 3.87 (98.3) | 25 |

| 5201.0600.025 | 6 | 6.51 (165.4) | 5.82 (147.8) | 25 |

Achieves a smooth bore, contamination free fluid path under clamping compression. Superior Steam-in-Place (SIP) stability.

Fluid path - gaskets

PTFE/stainess steel composite gasket. Minimal cold flow and creep compared to solid PTFE.

Fluid path - gaskets

Solid PTFE gasket for ultimate chemical resistance and purity. Precision engineered.

Fluid path - gaskets

USP Class VI compliant and animal derived component free (ADCF). Compliant with FDA regulations CFR 21 177.2600.

Fluid path - gaskets

Provide improved heat, acid and chemical resistance. Manufactured in accordance with ASME-BPE standards.

Fluid path - gaskets

To order a product or ask a question